Paperboard atomizing device of water-based printing machine

A processing device and printing machine technology, which is applied to printing machines, general parts of printing machinery, printing, etc., can solve problems such as bursting lines, improve the compressive strength of empty boxes, and solve the effects of low moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

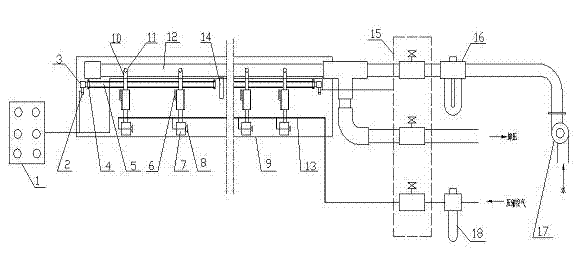

[0008] From figure 1 It can be seen that the water-based printing machine cardboard atomization treatment device of the present invention includes a control part, a transmission part, a spray part, and a baffle plate 9; Infrared detection probe 14; the transmission part is divided into left and right groups, each group includes motor 3, linear bearing 4, and screw rod 5: motor 3 is connected to control panel 1, encoder 2 is connected to motor 3, and screw rod 5 passes through the shaft coupling The device is connected with the motor 3, and its two ends are equipped with linear bearings 4, and the linear bearings 4 are installed in the sleeve connected with the baffle 9; the spray part includes the nozzle 7, the water pipe 12, and the air pipe 13: the nozzle 7 passes through the sleeve on the screw rod The water distribution pipe 10 on the 5, the flexible pipe 11 communicate with the water pipe 12, and the nozzle 7 links to each other with the air pipe 13 through the flexible p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com