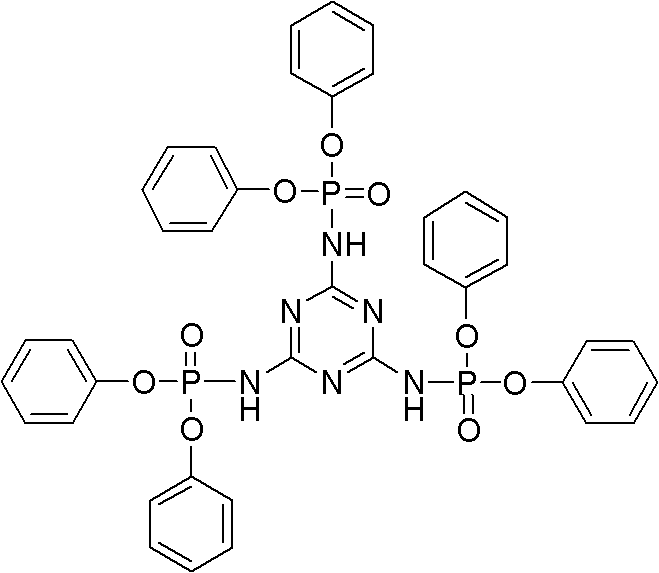

Hexaphenyl phosphate ester melamine salt fire retardant and method for preparing same

The technology of hexaphenyl phosphate melamine salt and melamine is applied in the field of hexaphenyl phosphate melamine salt flame retardant and its preparation, which can solve the problems of releasing toxic gas, generating corrosive substances, generating smoke, etc., and preventing dripping Falling phenomenon, good thermal insulation, the effect of preventing the spread and spread of flames

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

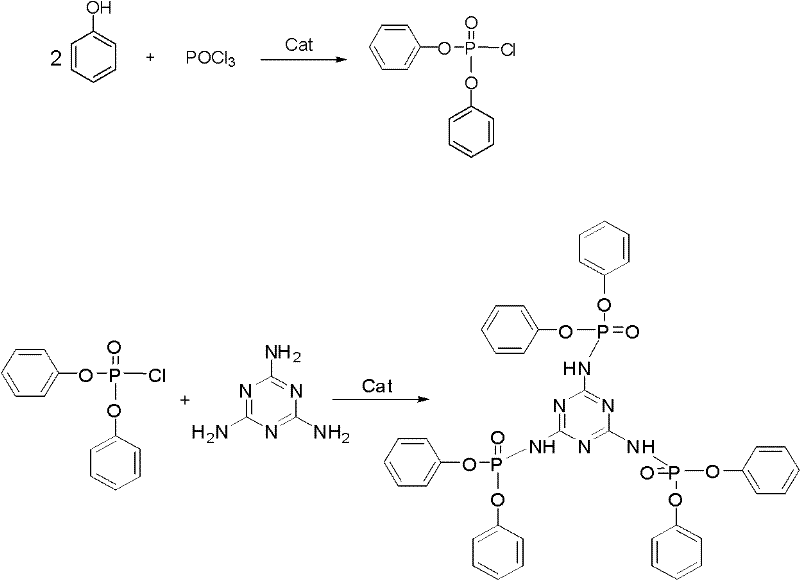

[0021] Add 0.1 mol of phosphorus oxychloride and 0.002 mol of anhydrous magnesium chloride to a 250ml three-necked flask equipped with a constant pressure dropping funnel, agitator and reflux device, stir and heat mechanically, add phenol in batches at 110°C and within 3 hours 0.2mol, heat preservation, mechanical stirring and reflux reaction for 36 hours, and then under reduced pressure distillation to obtain a pale yellow liquid, namely diphenylphosphoryl chloride (DPCP).

[0022] Put 0.03 mol of diphenylphosphoryl chloride from the previous step in a 500ml three-necked flask equipped with a stirrer and reflux device, mix 100ml of distilled water and 100ml of N,N-dimethylformamide (DMF) and add to In a three-necked flask, when the temperature is raised to 90°C, slowly add 0.01 mol of melamine, keep refluxing for 9 hours, then cool in an ice bath, filter with suction, wash with water, and dry to constant weight to obtain a white solid, which is hexaphenyl phosphate melamine salt....

Embodiment 2

[0024] Add 0.35mol of phosphorus oxychloride and 0.007mol of anhydrous magnesium chloride into a 500ml three-necked flask equipped with a constant pressure dropping funnel, stirrer and reflux device, stir and heat mechanically, and add phenol in batches at 110°C and within 3h 0.81mol, heat preservation, mechanical stirring and reflux reaction for 36h, and then under reduced pressure distillation to obtain a pale yellow liquid, namely diphenylphosphoryl chloride (DPCP).

[0025] Put 0.102 mol of diphenylphosphoryl chloride from the previous step in a 500ml three-necked flask equipped with a stirrer and reflux device, mix 150ml of distilled water and 150ml of N,N-dimethylformamide (DMF) and add to In a three-necked flask, when the temperature is raised to 90°C, slowly add 0.03 mol of melamine, keep refluxing for 9 hours, then cool in an ice bath, filter with suction, wash with water, and dry to constant weight to obtain a white solid, which is hexaphenyl phosphate melamine salt.

Embodiment 3

[0027] Add 1.15 mol of phosphorus oxychloride and 0.0115 mol of anhydrous magnesium chloride into a 500ml three-necked flask equipped with a constant pressure dropping funnel, agitator and reflux device, stir and heat mechanically, add phenol in batches at 110°C and within 3h 2.76mol, heat preservation, mechanical stirring, reflux reaction for 36h, and then under reduced pressure distillation to obtain a light yellow liquid, namely diphenylphosphoryl chloride (DPCP).

[0028] Put 0.18 mol of diphenylphosphoryl chloride from the previous step in a 500ml three-necked flask equipped with a stirrer and reflux device. Mix 200ml of distilled water and 200ml of N,N-dimethylformamide (DMF) and add to In a three-necked flask, when the temperature is raised to 90°C, slowly add 0.05 mol of melamine, keep refluxing for 9 hours, then cool in an ice bath, filter with suction, wash with water, and dry to constant weight to obtain a white solid, which is hexaphenyl phosphate melamine salt.

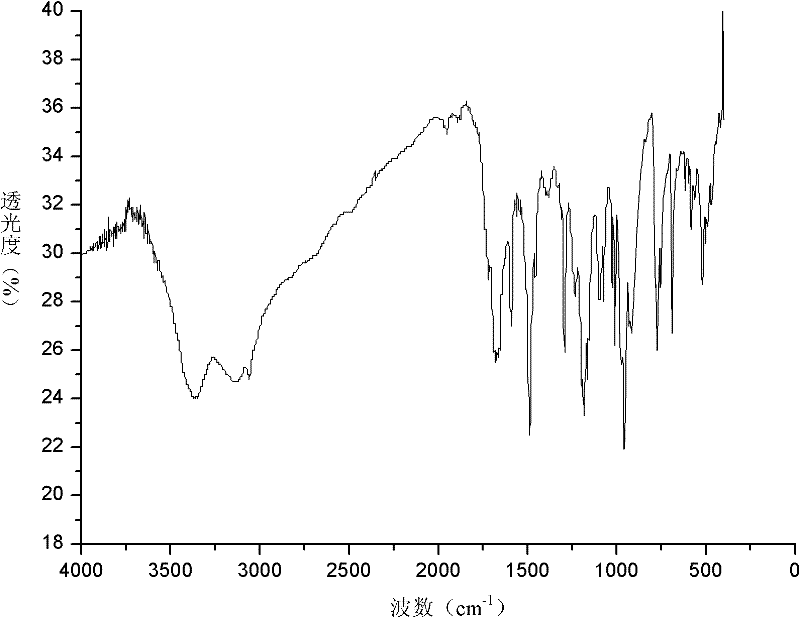

[0029...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com