Hot runner nozzle with composite structure and manufacturing method thereof

A technology of hot runner nozzle and composite structure, which can be used in manufacturing tools, welding media, gas flame welding equipment, etc., and can solve the problems of good wear resistance, poor thermal conductivity, and no wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

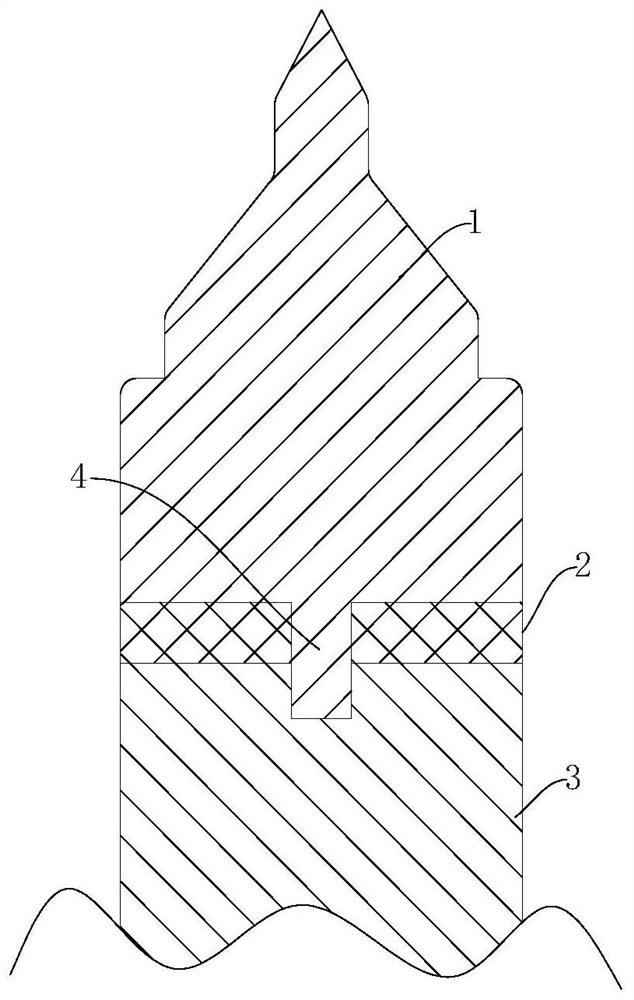

[0041] Such as figure 1 As shown, a hot runner nozzle with a composite structure provided in the embodiment of the present application includes a cemented carbide tip 1 and a part body 3 , and the cemented carbide tip 1 and the part body 3 are welded.

[0042] In the prior art, uniform materials are used, among which beryllium copper has good thermal conductivity, but is not wear-resistant; ordinary mold steel has poor thermal conductivity, but good wear resistance; and the cost of hard alloy is too high. This patent is to use a brazing process to compositely manufacture the hot runner nozzle on the basis of cost control. The use of a composite structure of different materials improves the wear resistance of the head of the hot runner nozzle, thereby increasing the service life.

Embodiment 2

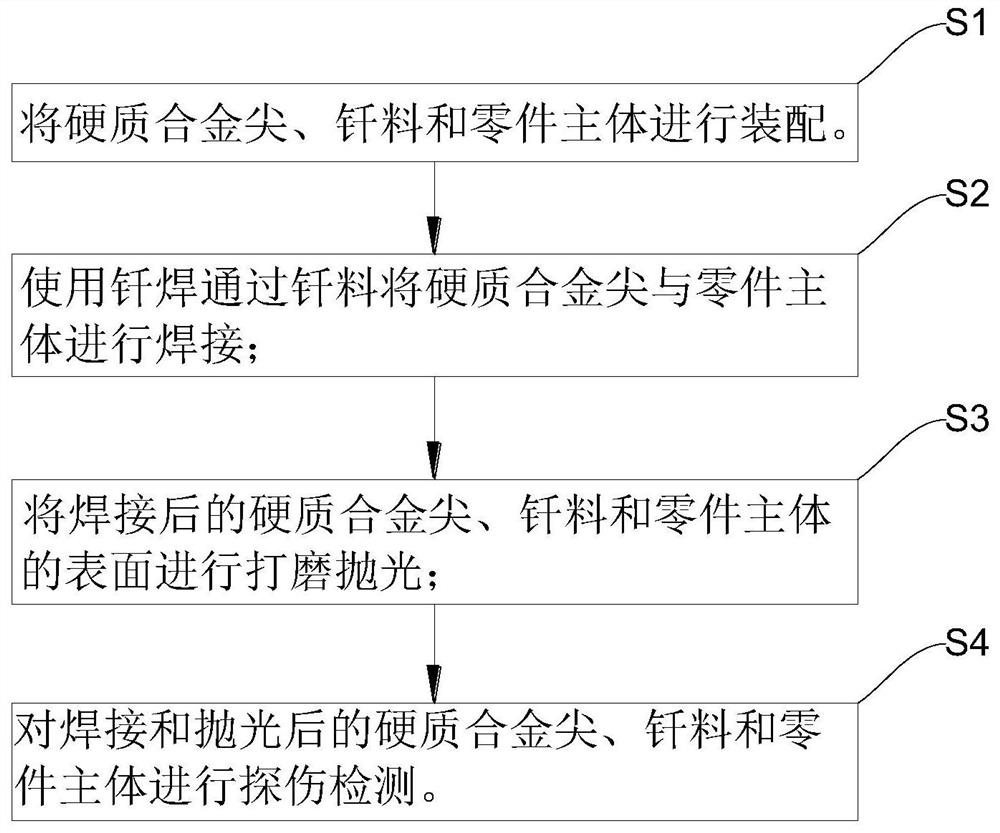

[0044] Such as figure 2 As shown, a method for manufacturing a hot runner nozzle with a composite structure provided in the embodiment of the present application includes the following steps:

[0045]S1: Assemble the cemented carbide tip 1, the solder 2 and the part body 3;

[0046] S2: use brazing to weld the cemented carbide tip 1 and the part main body 3 through the solder 2;

[0047] S3: grinding and polishing the surfaces of the welded cemented carbide tip 1, brazing material 2 and part main body 3;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com