Gloss composition, preparation method and gloss method

A composition and glossy technology, applied in the field of industrial manufacturing, can solve the problems of high production cost, low production efficiency, affecting physical and chemical indicators, etc., and achieve the effect of increasing decontamination and cleaning ability, reducing surface tension, and improving surface brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This example relates to a gloss composition of the present invention.

[0055] A glossy composition comprising (1) citric acid (CA), (2) hydroxyethylene diphosphoric acid (HEDP), (3) dodecylbenzenesulfonic acid (DBSA), wherein citric acid, hydroxy The mass ratio of ethyl diphosphoric acid and dodecylbenzenesulfonic acid is (1-1.5): (2-4): (1-1.5).

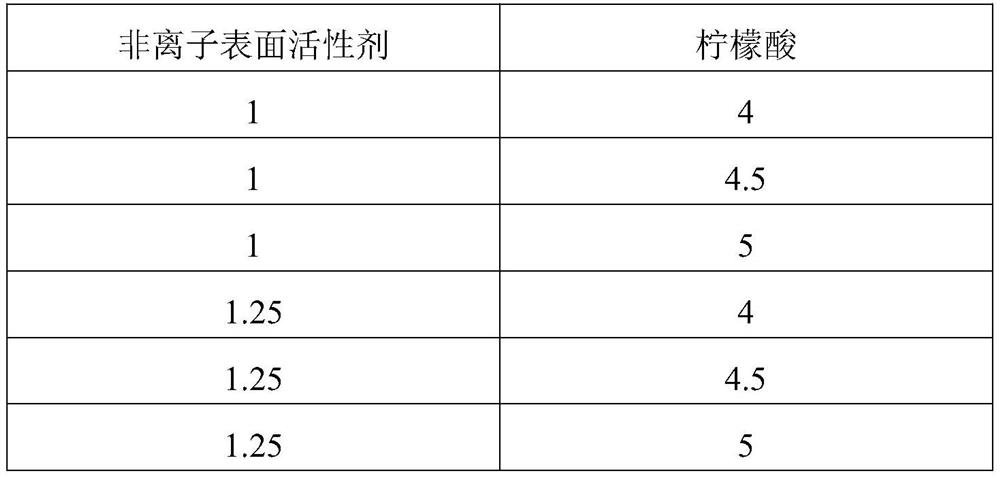

[0056] In some of these embodiments, the mass ratios of citric acid, hydroxyethylene diphosphoric acid, and dodecylbenzenesulfonic acid are as shown in the table below:

[0057]

[0058] Further, the luster composition further includes (4) a nonionic surfactant, wherein the mass ratio of the nonionic surfactant to citric acid is (1-1.5):(4-5).

[0059] In some of these embodiments, the nonionic surfactant is fatty alcohol polyoxyethylene ether.

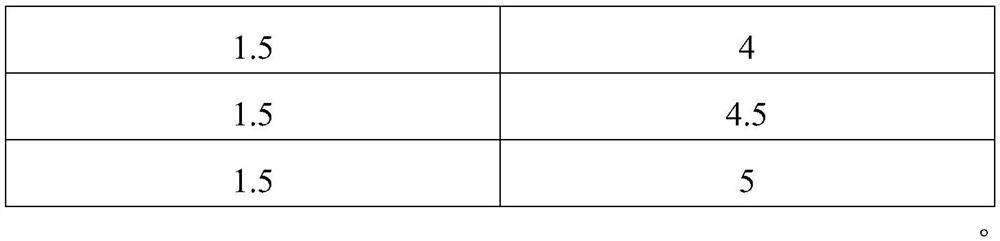

[0060] In some of these embodiments, the mass ratio of nonionic surfactant and citric acid is shown in the table below:

[0061]

[0062]

[0063] Further, the luster co...

Embodiment 2

[0080] This example relates to the preparation method of the glossy composition of the present invention.

[0081] A preparation method of gloss composition, comprising:

[0082] Step S102, adding a certain amount of citric acid to the aqueous solution at a temperature of 50-60°C to form a first solution;

[0083] Step S104, adding a certain amount of hydroxyethylene diphosphoric acid to the first solution, stirring and reacting at 50-60°C for 1-2 hours to form a second solution;

[0084] Step S106, when the free acidity of the second solution is 3-8 mgKOH / g and the total acidity is 40-70 mgKOH / g, add a certain amount of dodecylbenzenesulfonic acid to the second solution and stir evenly to form The third solution, wherein the third solution is transparent.

[0085] In step S102, the aqueous solution at 50-60°C is to pump a certain amount of water into a stainless steel reactor or an enamel reactor, and heat it to 50-60°C.

[0086] In some of the embodiments, the water is an...

Embodiment 3

[0100] This example relates to the gloss method of the present invention.

[0101] A gloss method of the present invention uses the gloss composition of Example 1 to perform gloss treatment on stainless steel fasteners.

[0102] An illustrative embodiment of the invention, the gloss method, comprises:

[0103] Step S202, immerse the stainless steel fastener into the solution containing the luster composition, immerse and rotate at 30-60°C for 3-15 minutes.

[0104] In step S202, the stainless steel fastener is a stainless steel fastener that has undergone molding, degreasing, and polishing.

[0105] In some of the embodiments, in the solution containing the gloss composition, the mass ratio of the gloss composition is 5-25%.

[0106] In some of these embodiments, the preparation method of the solution containing the luster composition is:

[0107] The luster composition is diluted by mass ratio of 5-25%.

[0108] In step S202, the solution containing the luster composition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com