Extrusion-resistant and fatigue-resistant steel wire rope for rotary digging machine

A fatigue-resistant and steel wire rope technology, applied in the field of steel wire ropes, can solve the problems of heavy load bearing, poor flexibility of steel wire ropes, inability to withstand pressure, etc., to improve extrusion resistance and impact resistance, increase effective area and density, and enhance softness The effect of resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

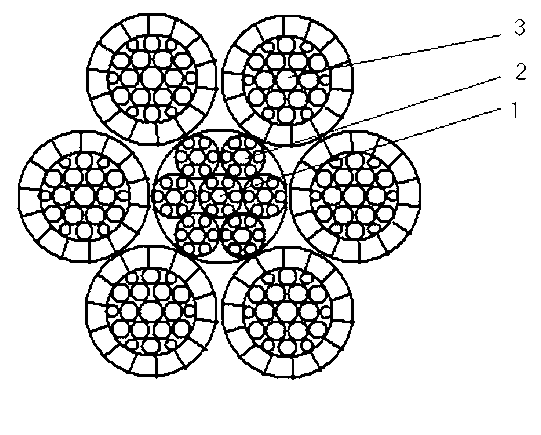

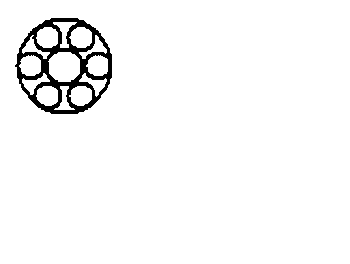

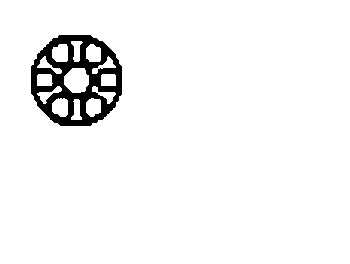

[0022] see Figure 1-4 , Extrusion-resistant, fatigue-resistant steel wire rope for rotary excavators, type 6×K33WS -¢28mm, including central strand 1 (¢3.9mm), outer strand 2 (¢3.6mm), main strand 3 (¢9.4mm) ; The central strand 1 and the outer strand 2, the center includes a central steel wire and 6 steel wires evenly wrapped and twisted outside the central steel wire; the main strand 3 adopts the combined structure of "WS" Valinton-Silu type: the central steel wire 1 Steel wires with a diameter of 1.5mm, 6 steel wires in the first layer, 1.4mm in diameter, 12 steel wires in the second layer, including 6 thick steel wires with a diameter of 1.5mm, 6 thin steel wires with a diameter of 1.1mm, and the third layer There are 14 steel wires, 6 thin steel wires are embedded in the outer raised parts of the first layer of steel wires, thick steel wires are respectively embedded in the 6 gaps formed between the 6 steel wires of the inner layer; the first layer of steel wires are in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com