Manometric bomb for primer performance test

A blaster and test technology, applied in ammunition tests, weapon accessories, ammunition, etc., can solve the problem of single test parameters, and achieve the effect of good assembly process and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

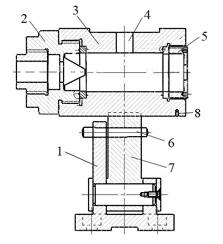

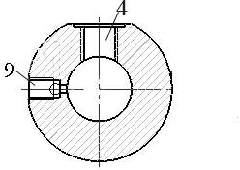

[0017] Refer to attached Figures 1 to 7 Shown, the designed airtight blaster of the present invention adopts special steel material, by blaster support 1, blaster pillar 7, blaster cover 3, blaster through cover 2, blaster end cap 10, primer end cap 5, It consists of a pressure-resistant light-transmitting glass sheet 11, a copper sealing gasket and a pressure relief plug.

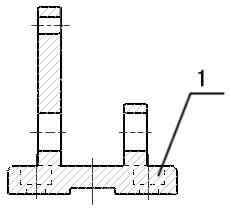

[0018] attached by figure 1 , 2 As can be seen, there are two supports, high and low, on the base plate of the blaster support 1, and the high support has two holes up and down, and the low support has a hole. The inner diameter of cylindrical explosive device cover 3 is 35.68mm, and the outer diameter is 80mm. In the middle part of the side of the explosive device cover, a cuboid pillar 7 is welded, and two holes are arranged on the pillar upper and lower. When installing, align the two holes of the pillar 7 with the corresponding holes on the support 1, wherein the lower holes are connected together...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com