Field device for determining or monitoring a physical or chemical process variable

A field equipment, chemical process technology, applied in the direction of program control, general control system, CAD circuit design, etc., can solve problems such as high risk, impact partition, functional failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

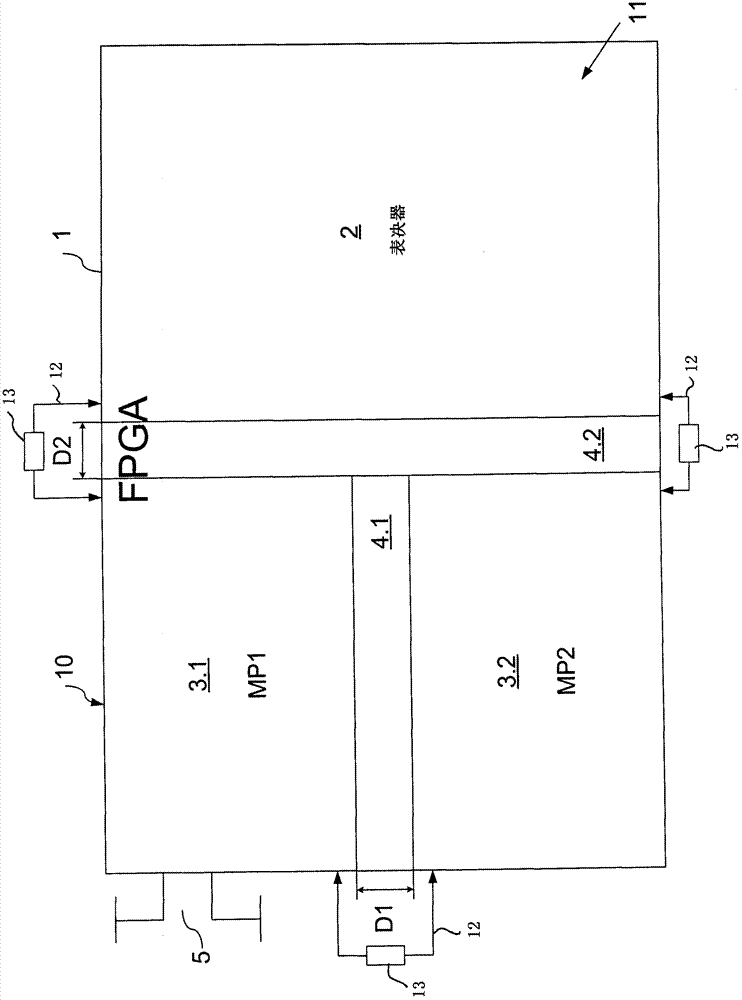

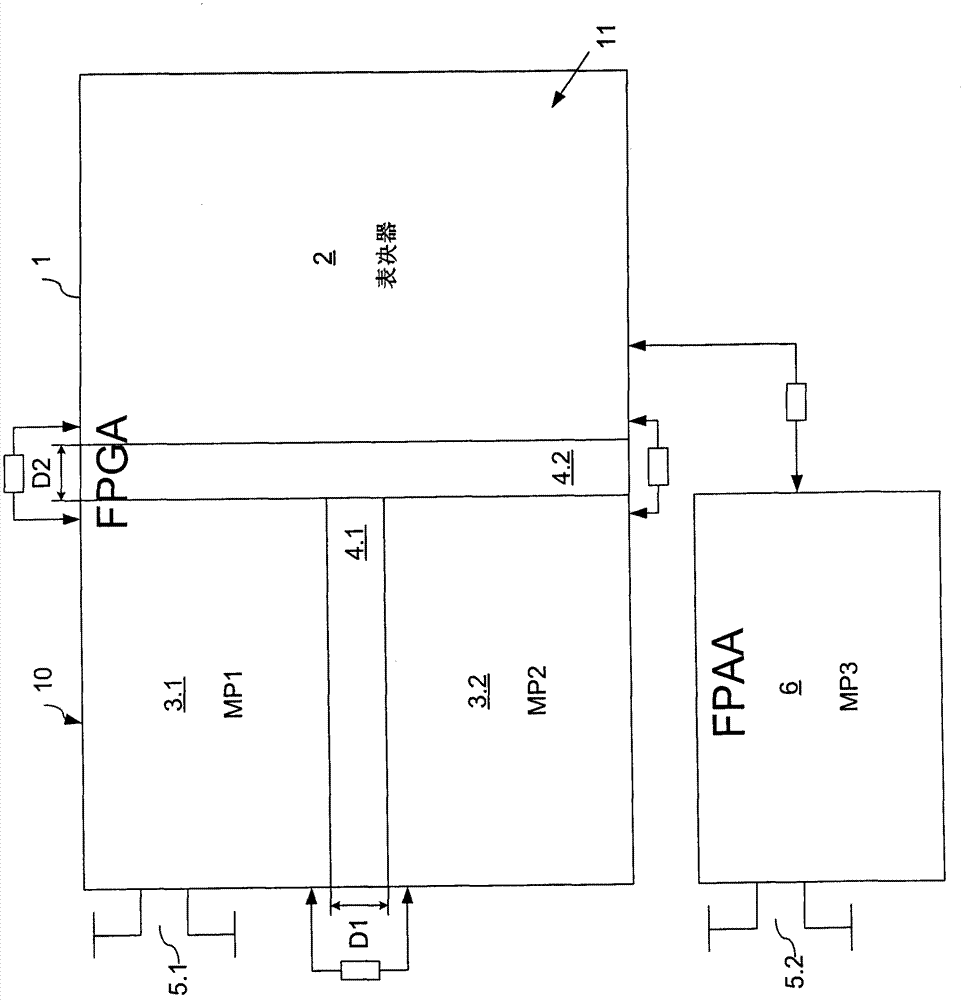

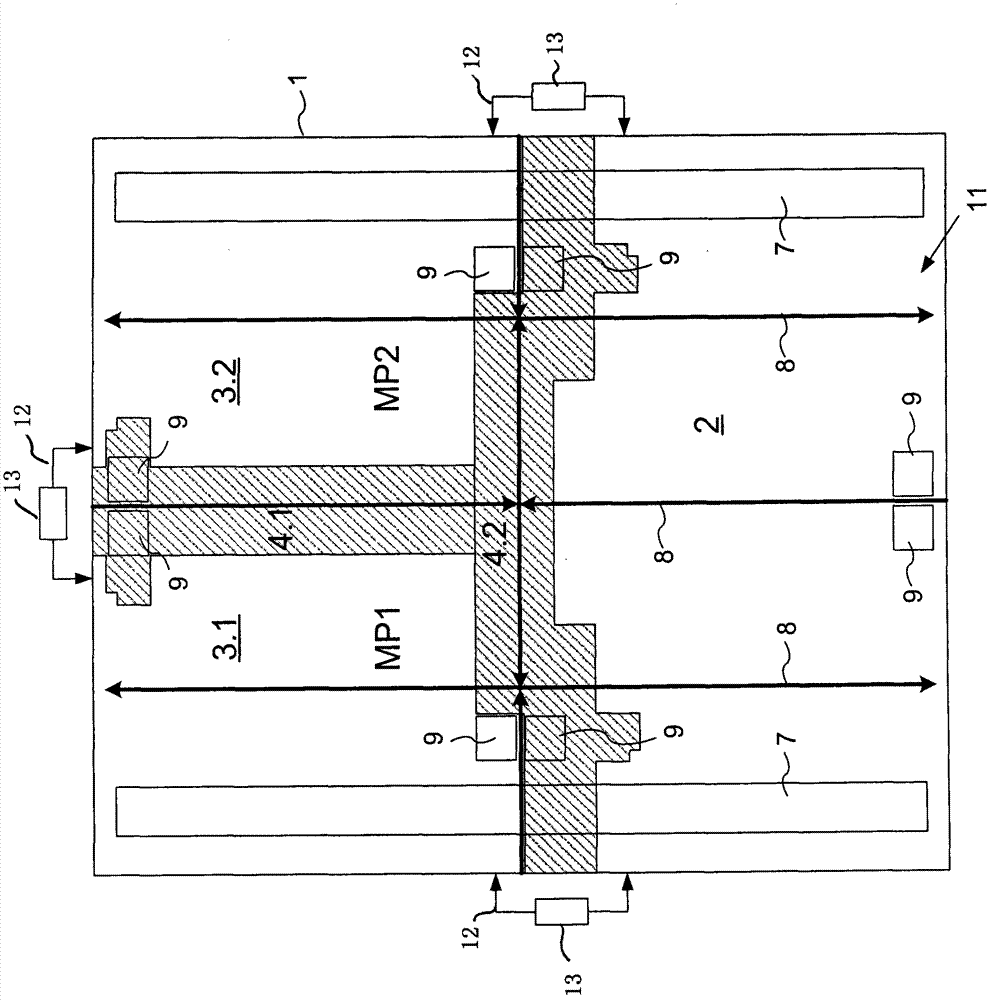

[0031] figure 1 Shows a schematic diagram of a control / evaluation unit 10 of a field device according to the invention with two partitions 3.1, 3.2 in which a digital measurement path MP1, MP2 is partially dynamically reconfigured. The field device itself is not shown separately in the figures. Different types of field devices are supplied and sold by the Endress+Hauser group.

[0032] Each of the two equivalent measurement paths MP1, MP2 consists of one or more software-based and / or hardware-based functional modules, which are also in figure 1 not shown separately. The control / evaluation unit 10 is implemented on the FPGA 1 . Preferably, a standard FPGA 1 is used as basis for the solution according to the invention. Depending on the required safety standards, the two measurement paths MP1 , MP2 are designed in a redundant and / or diverse manner. In the measurement paths MP1, MP2, the required functional modules are partially dynamically reconfigured as required. The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com