Electronic circuit board moistureproof process

An electronic circuit board and process technology, which is applied to the secondary treatment of printed circuits and the application of non-metallic protective layers. The effect of parameter guarantees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

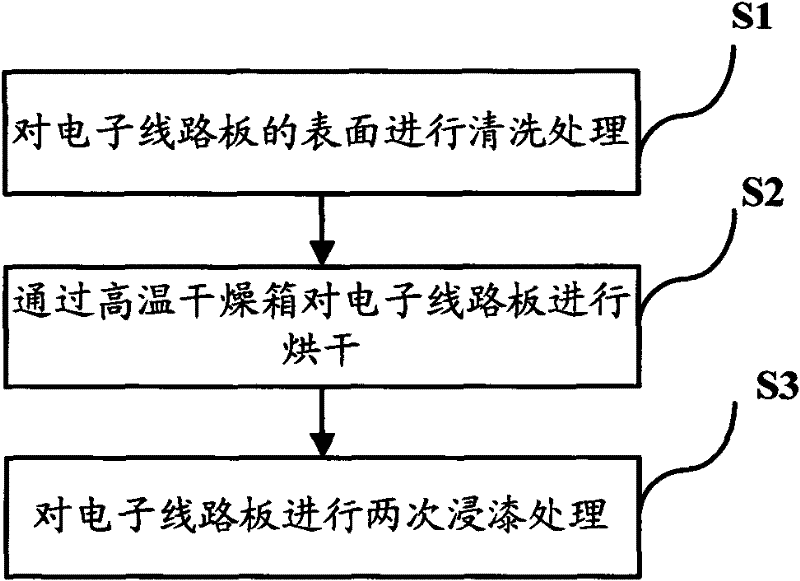

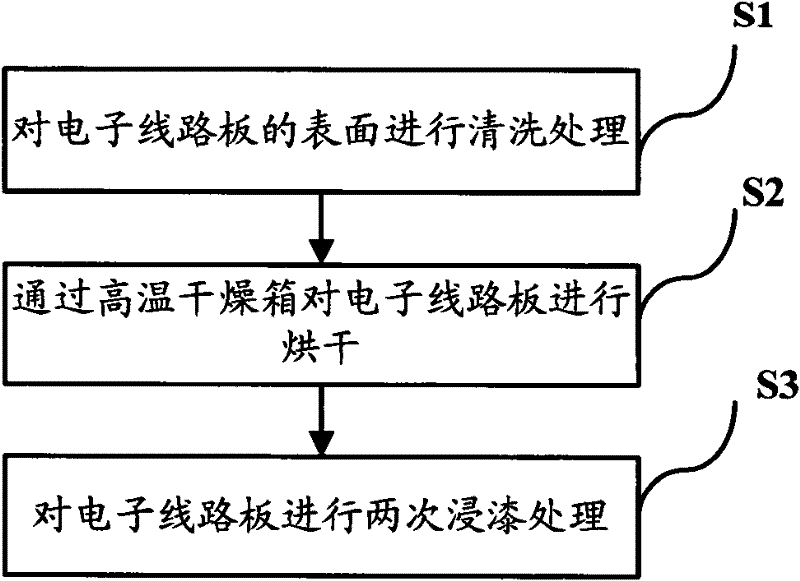

[0018] figure 1 It is a flow chart of the electronic circuit board moisture-proof process of the present invention, as shown in the figure. The electronic circuit board moisture-proof process of the present invention comprises the following steps:

[0019] Step S1, cleaning the surface of the electronic circuit board, including cleaning oil mist, dust and metal powder on the surface of the electronic circuit board.

[0020] Oil mist, dust and metal powder on the surface of the electronic circuit board can easily cause a decrease in the insulation resistance between components, and even cause damage to components and electronic circuit boards.

[0021] In step S2, the electronic circuit board is dried in a high-temperature drying ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com