Cigarette paper with low ignition tendency and preparation method

A cigarette paper and tendency technology, which is applied in the field of preparation of cigarette paper with low ignition tendency, to achieve the effect of improving good runnability, high flame-out rate, and ensuring coating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation of a cigarette paper with low ignition tendency basically adopts the existing papermaking process, such as dispersing and beating the fiber raw materials, adjusting the ratio of long and short fibers, adding fillers and functional additives, and then forming by dehydrating paper, and then Squeezing, drying, coiling and rewinding complete the manufacture of cigarette paper.

[0023] The low ignition tendency cigarette paper of the present invention comprises a kind of ordinary cigarette paper made by papermaking process, which is characterized in that the inner surface of the ordinary cigarette paper is painted or printed with film-forming agent, viscosity The coating liquid film layer composed of regulator and filler constitutes a coating tape.

[0024] The film-forming agent is one or more combinations of starch, cyclodextrin, maltodextrin, pectin, gelatin; the viscosity modifier is alkali metal alginate, polyvinyl alcohol, sodium carboxymethyl cellulos...

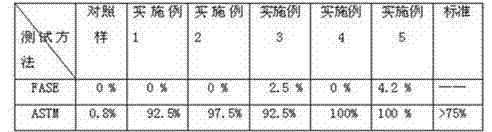

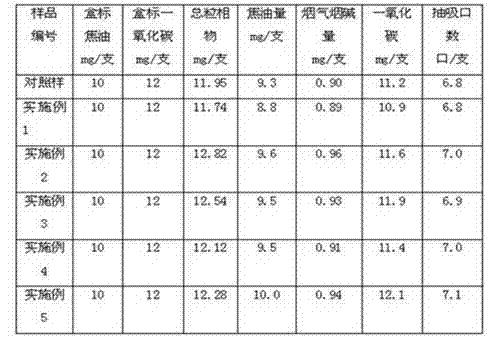

Embodiment

[0034] The preparation and screen printing coating of the cigarette paper in the low-ignition cigarette paper proposed by the present invention will be described below.

[0035] 1. Cigarette paper

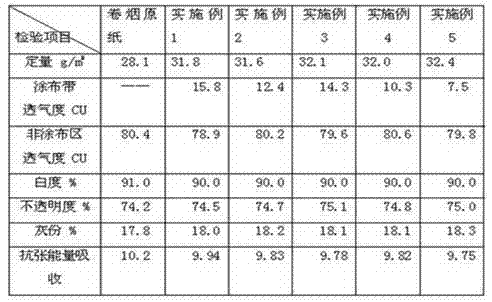

[0036] 1. Characteristics of cigarette paper

[0037] The quantitative range of cigarette paper is 20-100 g / m 2 , the air permeability of cigarette paper is 20-90 Coresta (CORESTA);

[0038] 2. Using a variety of inorganic fillers

[0039] (1) Calcium carbonate, light calcium carbonate powder or freshly prepared calcium carbonate suspension, the amount used is in the range of 15-50% by weight in the finished paper;

[0040] (2) Magnesium-containing substances with a large specific surface area can be magnesium oxide powder, magnesium hydroxide powder or freshly prepared magnesium hydroxide, and the magnesium ion content in the finished paper is in the range of 5-40% by weight based on magnesium hydroxide;

[0041] (3) Trihydric aluminum and aluminum salt compounds ...

Embodiment 1

[0054] Get 700 kg of wood pulp, add 500 kg of calcium carbonate, prepare 40% by weight of potassium citrate and 6% by weight of sodium citrate, add it at the place where the combustion aid is added, and produce cigarette paper according to the conventional papermaking method, and control it on the equipment The characteristics of cigarette paper are: quantitative 28 g / m 2 , Air permeability 80 Coresta.

[0055] At room temperature, add a certain mass of calcium carbonate as a filler in the coating liquid preparation barrel to prepare a suspension with a mass percentage concentration of 50%, and stir evenly; add 2% mass percentage concentration of alkali metal algae to it. salt and 1% polyvinyl alcohol as a viscosity regulator, after stirring evenly; then add 5% starch, 8% cyclodextrin and 12% maltodextrin with a concentration of mass percent to it, as a film-forming agent, stir uniform. The screen printing coated tape width was 6mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com