Furnace body of microwave oven

A microwave and furnace technology, which is used in household stoves/stoves, roasters/barbecue grids, and household heating, etc., can solve the problems of low efficiency, single heating method, and easy smell, so as to maintain nutrition and moisture, improve Cooking environment, improving the effect of a single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

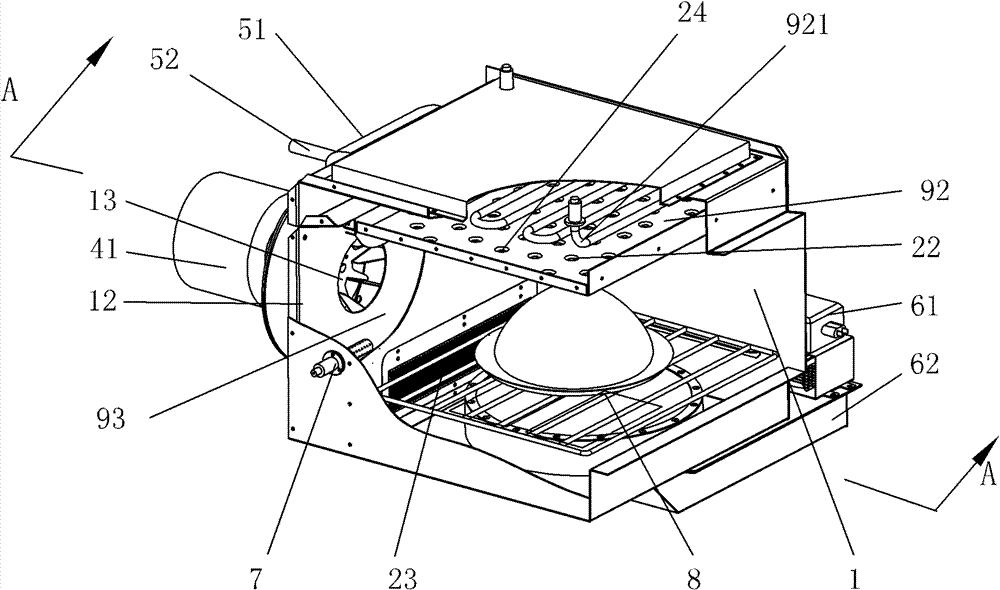

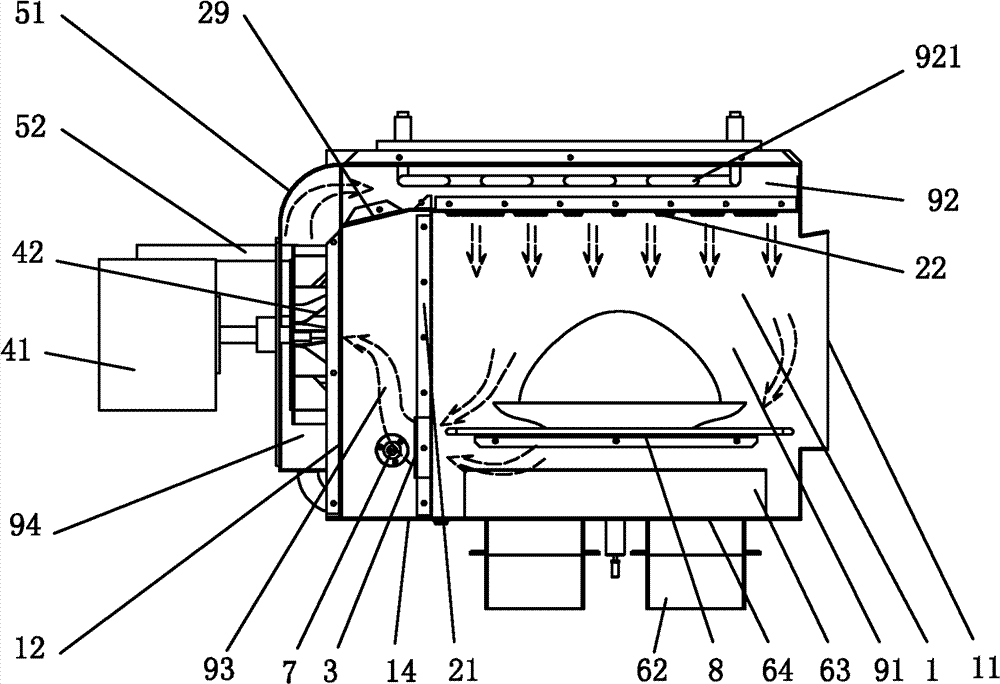

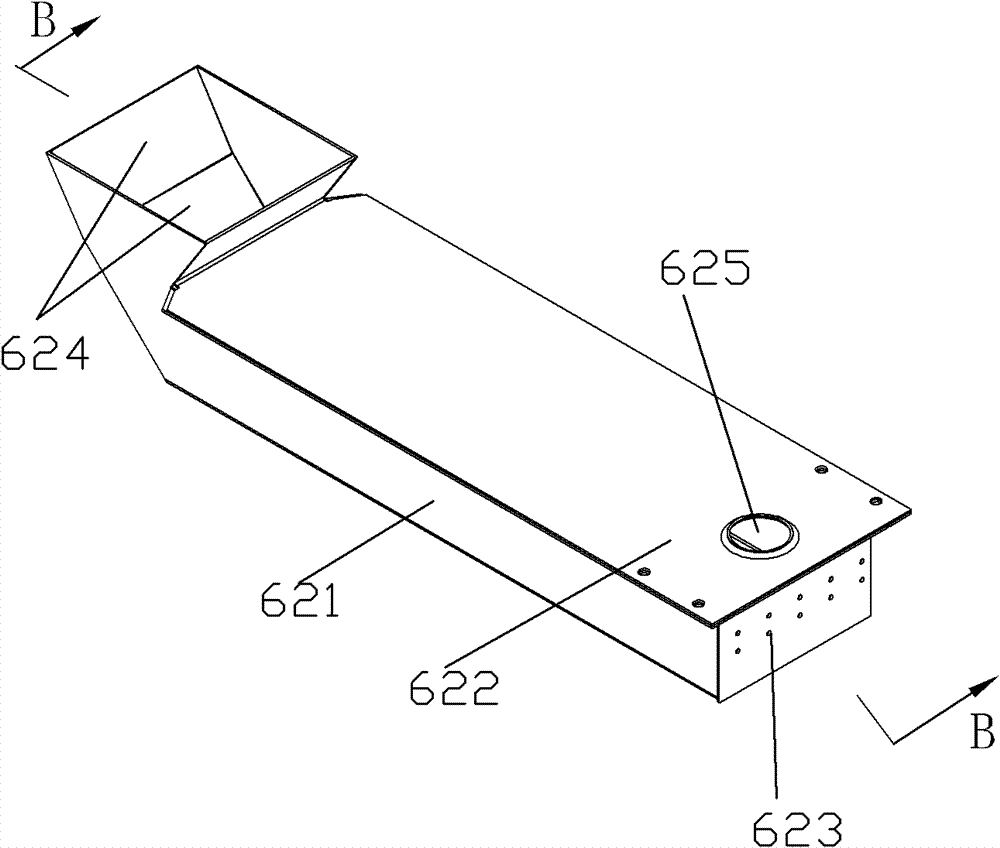

[0025] Such as Figure 1 to Figure 8 As shown, a microwave oven body includes an oven shell 1 with a hollow structure inside, an oven door 11 on the front panel of the oven cavity, and an "L"-shaped wind deflector that separates the oven cavity inside the oven shell. Divided into a first cavity 91 and a second cavity, the wind deflector is composed of two vertical plates 21 and a horizontal plate 22 that are perpendicular to each other. A partition 29 extends from the corner of the air deflector to the inner wall of the rear plate 12 of the furnace cavity, in a horizontal state, and divides the second cavity into a horizontal heating cavity and a vertical circulating air duct. The heating cavity 92 is located in the furnace cavity At the top, the circulating air duct 93 is located at the rear of the furnace cavity. On the horizontal plate of the air deflector 2, there is an air guide hole array 24, which can connect the heating cavity 92 and the first cavity 91, and the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com