Transpiration material

An evapotranspiration and woven fabric technology, which is applied in the fields of pesticides, animal repellents, botanical equipment and methods, etc., can solve the problems of chemical leakage and limitation of the effective period of evapotranspiration materials, so as to achieve the effect without reducing the effectiveness and improving the retention amount. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0097] Although the present invention will be specifically described below in examples, it is not limited to these examples.

[0098] (Reference example 1~4)

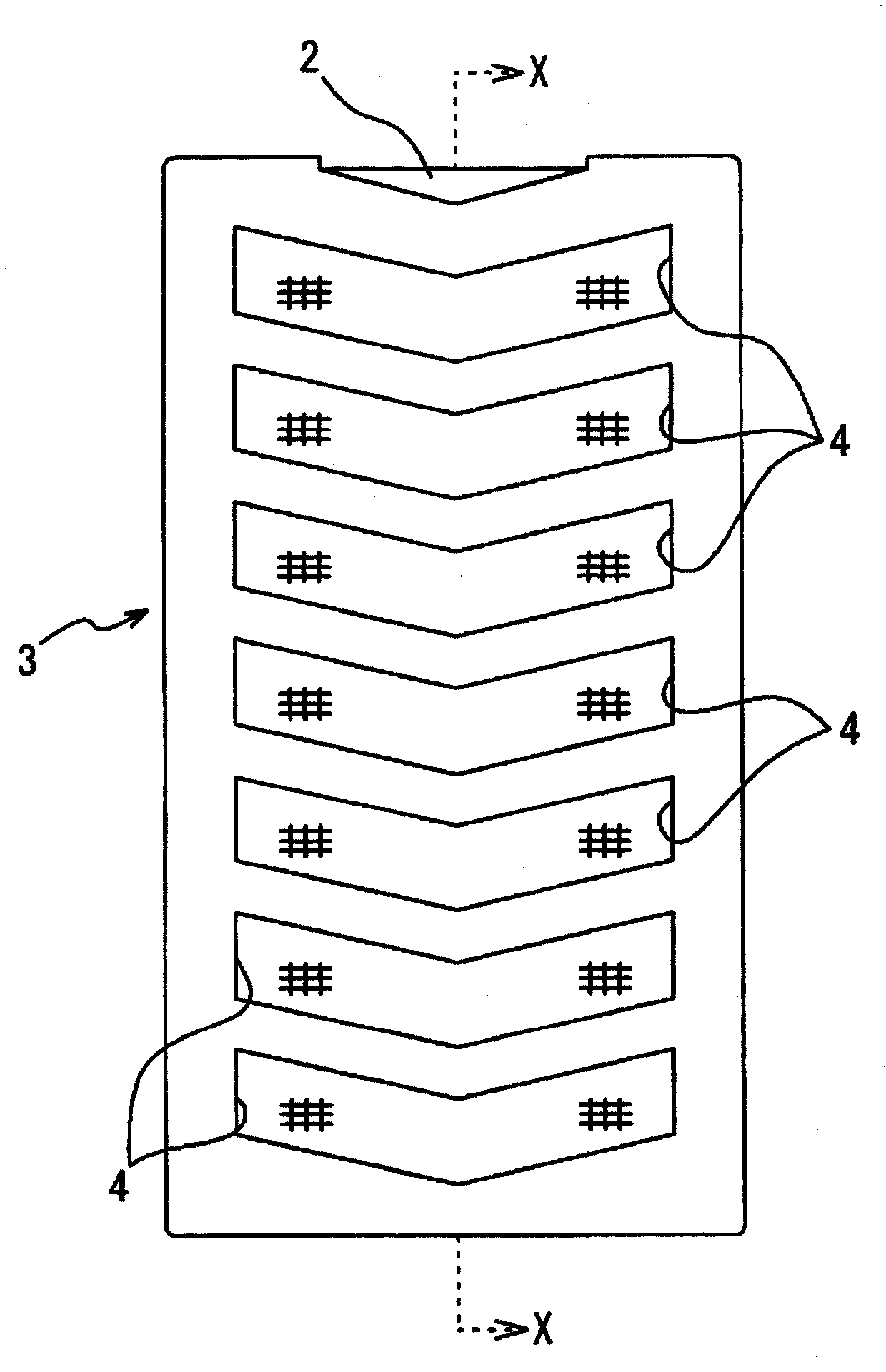

[0099] Lace-based yarns are produced by subjecting polyester multifilaments (50 filaments) to deformation processing by twisting-heat setting-untwisting method to crimp at a crimp rate of 13%. A mesh-like woven fabric (net) made by mesh weaving.

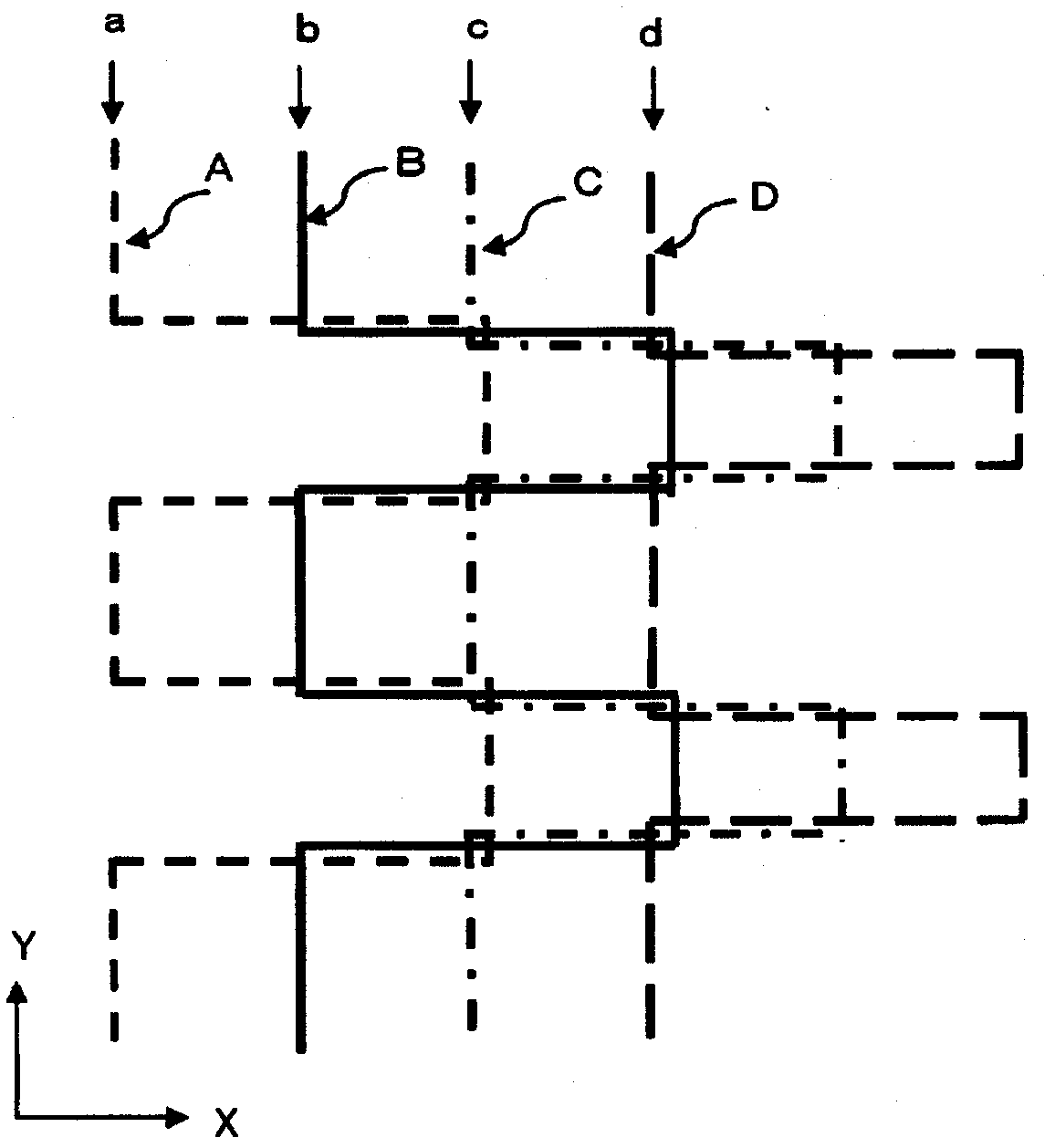

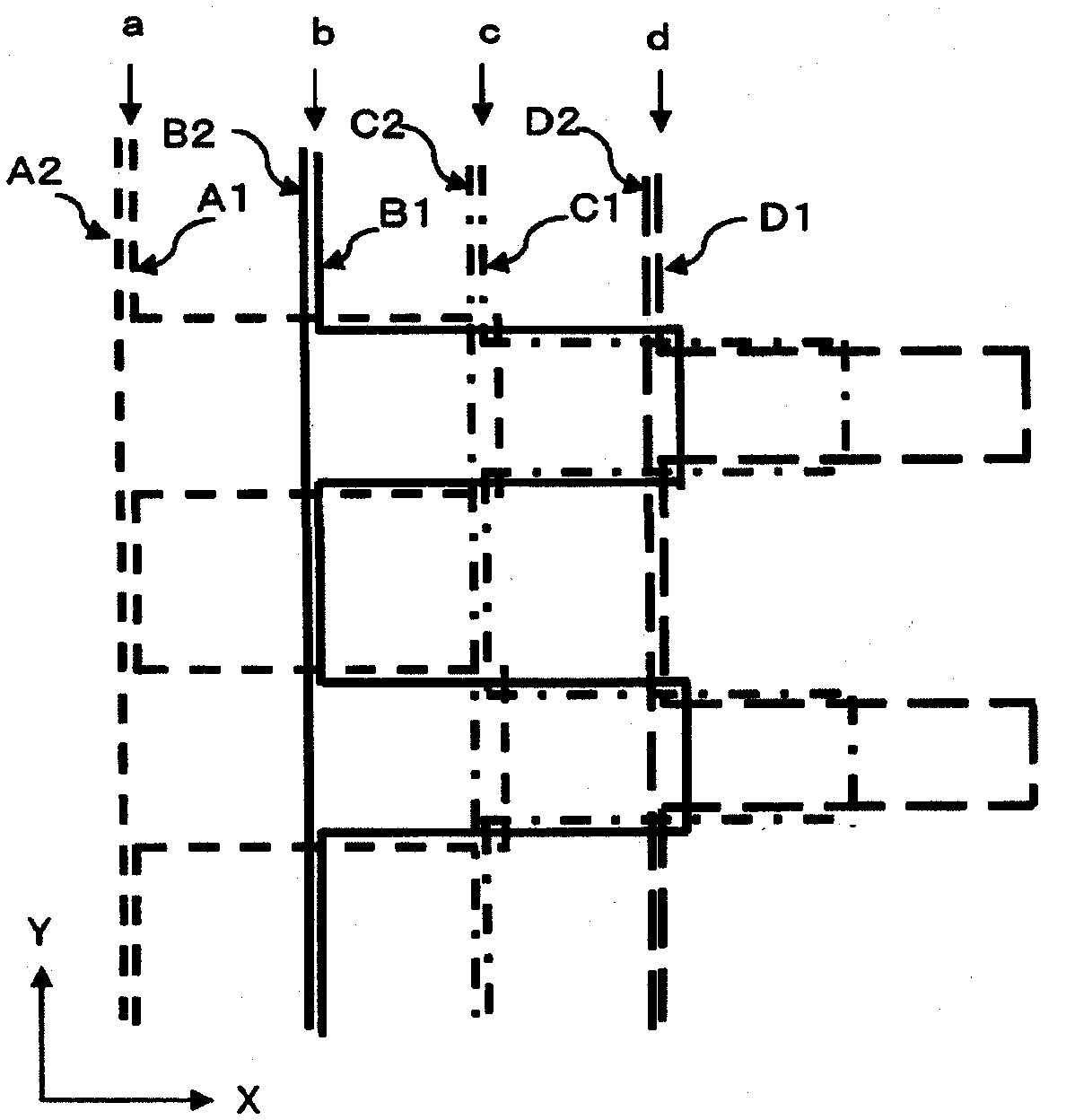

[0100] That is, in figure 2 In the shown lace mesh weaving mode, by changing the number of threads used in each column, the ratio of the number of warp threads passing through in the warp direction to the number of warp threads wound on other warp threads, winding The positions of other warp threads (skipping several warp threads and winding), thereby making the number (x) of warp threads arranged in the weft direction and the number (y) of warp threads arranged in the warp direction are respectively based on A reticulated fabric (net) produced by lace mesh weaving.

reference example 1

[0101] Reference example 1: x=2, y=2

reference example 2

[0102] Reference example 2: x=3, y=2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com