Wheel suspension for motor vehicles

A motor vehicle and suspension technology, applied in the field of motor vehicle wheel suspension structure, can solve problems such as damage to the ball screw mechanism, filter blockage, screw/nut unit corrosion, etc., and achieve the effect of reliable pressure balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

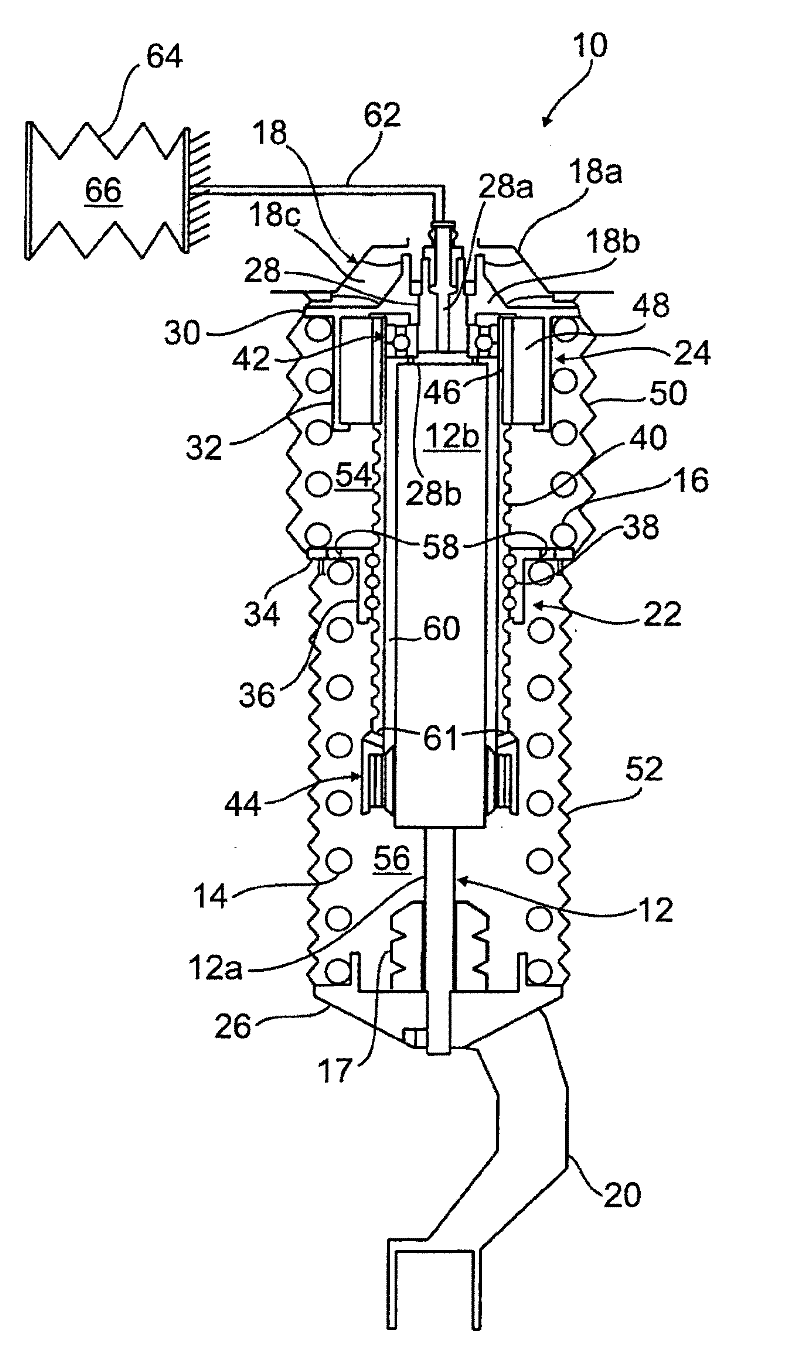

[0022] figure 1 Schematically shows an active spring strut assembly 10 for a motor vehicle wheel suspension structure, the spring strut assembly is mainly composed of a telescopic buffer 12, a support spring 14, an energy storage spring 16, an upper shock absorber support 18 and The lower damper support 20 constitutes.

[0023] The height adjustment and / or roll stability of the motor vehicle body is controlled by means of a height adjustment device 22 , which is driven by an electric motor 24 .

[0024] The damper 12 is fastened on the lower spring washer 26 by its downwardly protruding piston rod 12a. The spring retainer 26 and the shock absorber support 20 form a composite part which is articulated or fastened in a known manner to a wheel guide element of a motor vehicle wheel suspension, for example a control lever or a wheel bearing. Furthermore, a rubber-elastic stop damper 17 is provided as an additional spring on the spring washer 26 .

[0025] In contrast, the dampe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com