Light-amplifying glass

A light amplification and glass technology, applied in optics, light guides, lasers, etc., can solve the problems of inability to obtain amplification and insufficient suppression, and achieve the effect of increasing the number of repetitions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

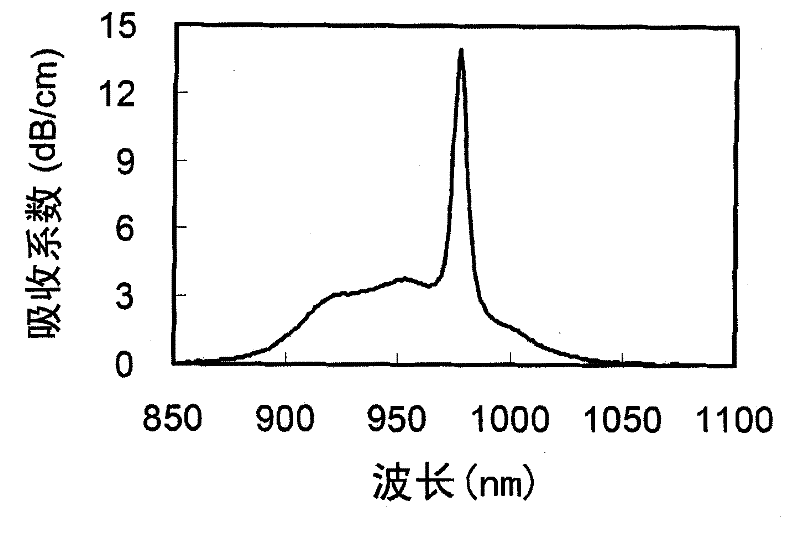

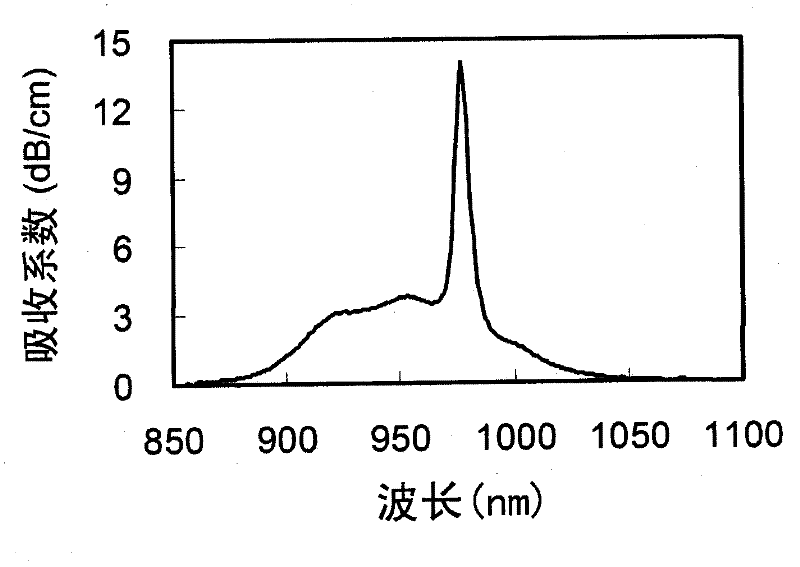

[0043] In Table 1-3 by Bi 2 o 3 to CeO 2 The glass with the composition expressed in mol% in the column of is produced by the melting method of melting at 1150°C. In addition, the glass transition temperature Tg (unit: ° C), the relative luminous intensity E for a wavelength of 1064 nm, the luminous lifetime τ (unit: ms) for a wavelength of 1064 nm, and the absorption coefficient A (915) for a wavelength of 915 nm (unit: : dB / cm), the absorption coefficient A(940) (unit: dB / cm) for the wavelength of 940nm, the absorption coefficient A(p) (unit: dB / cm) for the peak of the wavelength of 940-990nm, for 915 The index of the flatness (flatness) of the absorption coefficient in the wavelength range of ~940 nm, that is, the ratio A' between the maximum value and the minimum value of the absorption coefficient is shown in the table.

[0044] Examples 1 to 20 are examples, and examples 21 and 22 are comparative examples. All of the glasses in Examples 1 to 20 have a Tg of 430° C. o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com