Spindle-pushing device for metal extruding machine

A metal extrusion and pusher technology is applied in the field of ingot pusher devices of metal extruders, which can solve the problems of poor structure precision and low degree of mechanization of the ingot pusher device, so as to improve the production efficiency, improve the degree of mechanization, and ensure the accuracy of equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

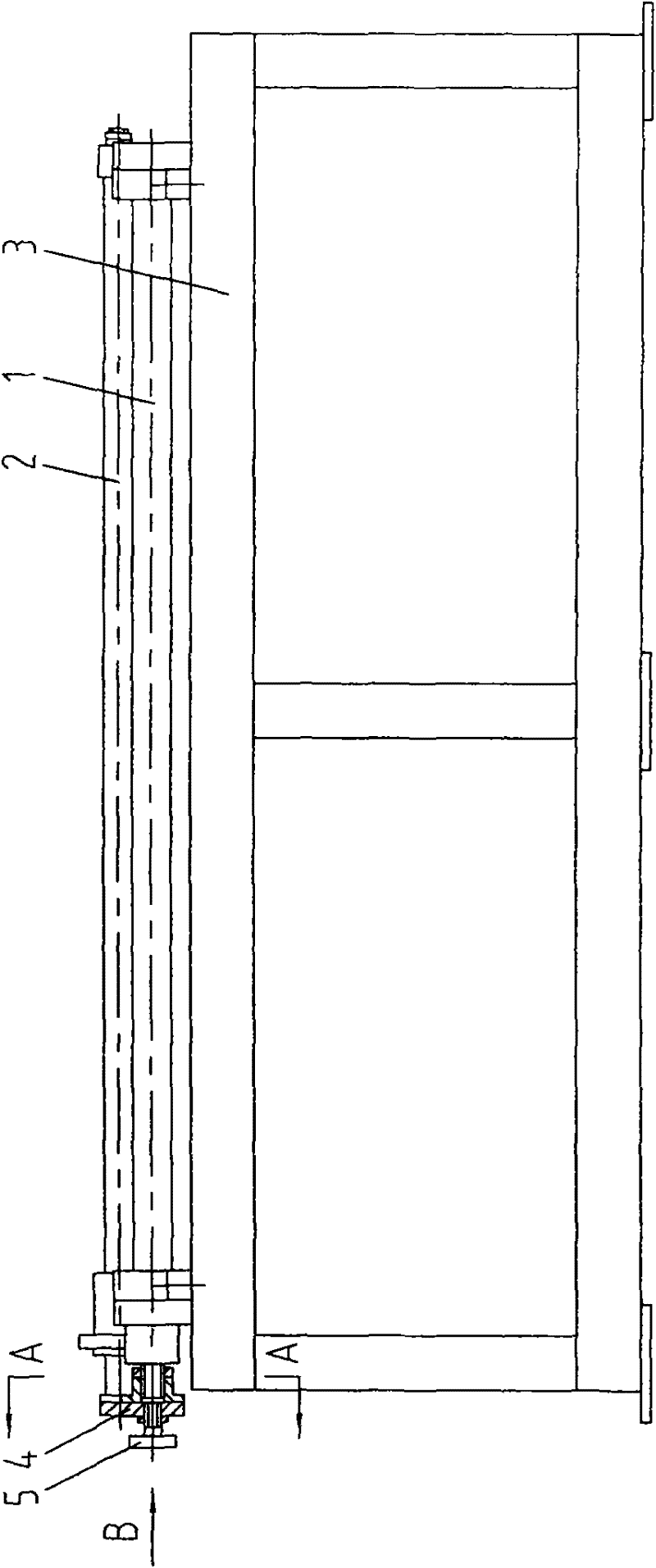

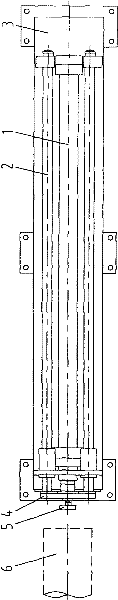

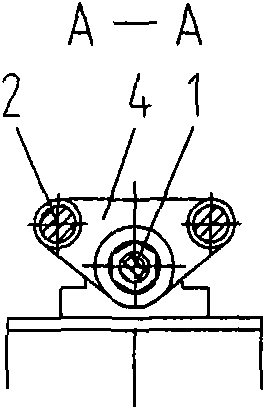

[0013] Such as figure 1 , 2 , 3 and 4, a metal extrusion machine ingot pushing device is composed of a hydraulic cylinder 1, a guide rod 2, a bracket 3, a connecting plate 4, and a push head 5, and the hydraulic cylinder 1 and two guide rods 2 are installed on the bracket 3, the hydraulic cylinder 1 and the front ends of the two guide rods 2 are connected and fixed together by the joint plate 4, and the push head 5 is installed on the front end of the joint plate 4.

[0014] Due to the use of two guide rods 2 for guidance, excessive downward deflection of the piston rod of the hydraulic cylinder 1 during the ingot pushing process is avoided, ensuring the accuracy of the equipment.

[0015] When pushing the ingot, the back cavity of the hydraulic cylinder 1 is supplied with high-pressure oil, the piston moves forward, drives the connecting plate 4, and drives the push head 5 to move forward, and the push head 5 pushes the spindle 6 to make a linear motion, thereby completing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com