Aluminum alloy brazing sheet and heat exchanger

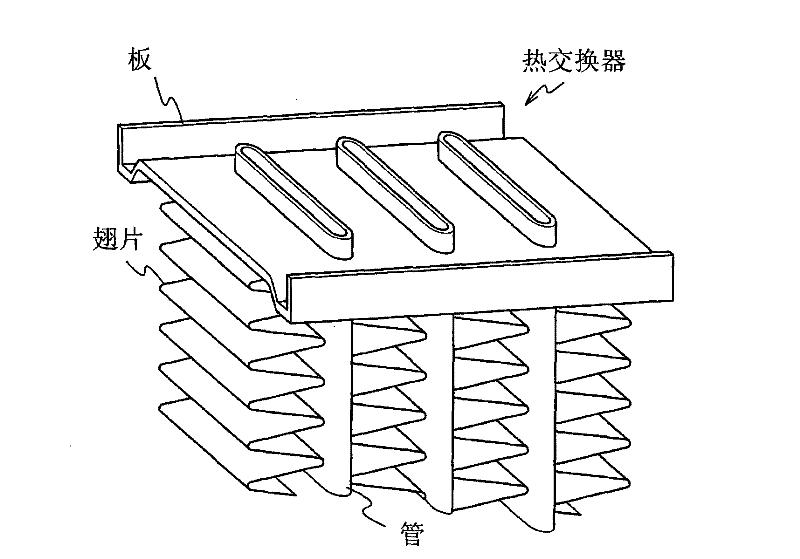

A technology of heat exchangers and aluminum alloys, applied in heat exchange equipment, heat exchanger shells, indirect heat exchangers, etc., can solve problems such as joint gaps, and achieve good brazing and corrosion resistance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

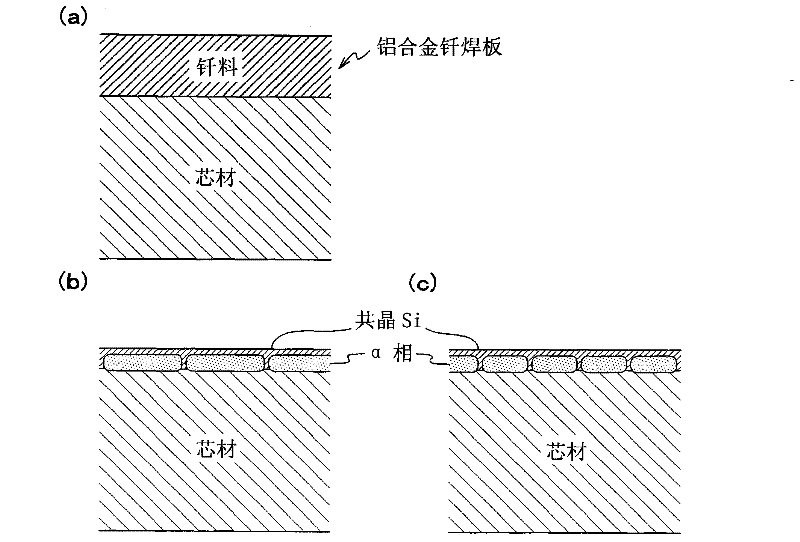

Method used

Image

Examples

Embodiment 1

[0070] As mentioned above, the form for carrying out this invention was demonstrated, and the implementation which confirmed the effect of this invention is compared with the comparative example which does not satisfy the requirement of this invention below, and it demonstrates concretely. In addition, this invention is not limited by this Example.

[0071] (production of test materials)

[0072] Through continuous casting, melting and casting have the aluminum alloys for the core material (C) and the aluminum alloys for the brazing material (F) having the composition shown in Table 1, as well as the sacrificial anode material (S) containing Zn: 3 mass % aluminum alloy to obtain ingots. The surface of the ingot was face-milled, and the ingot for brazing filler metal and sacrificial anode material was cut to a predetermined thickness matching the coating ratio to form a thick plate, and then a homogenization heat treatment was performed for 4 hours. The homogenization heat tr...

Embodiment 2

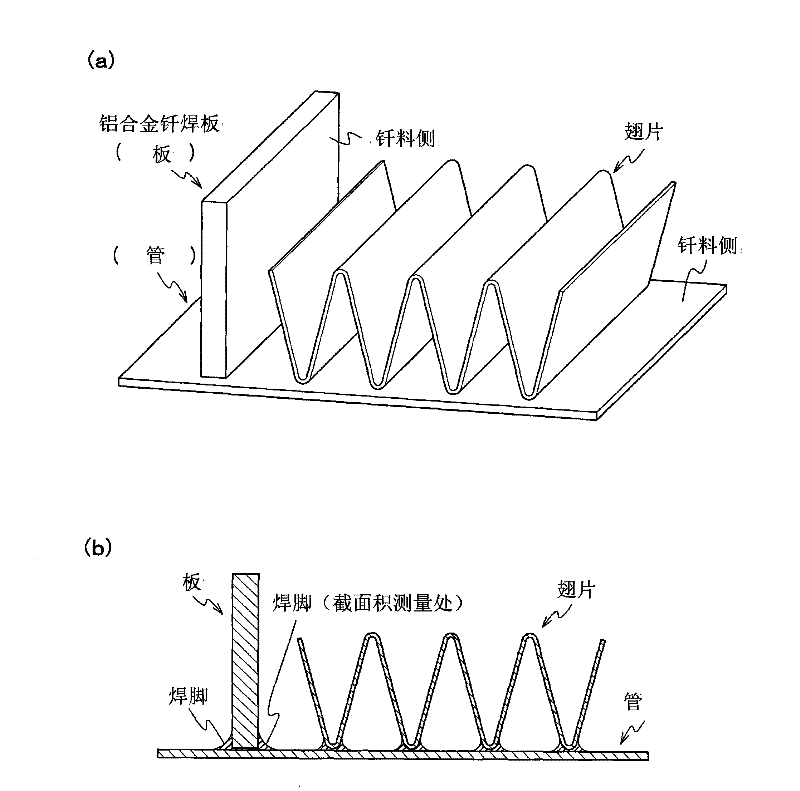

[0093] (Manufacturing of brazed structures)

[0094] For the test materials No. 1 and 5 (see Table 1) of Example 1, the pipe was roll-formed into a flat pipe shape, and the state of joining (splicing) on both sides was simulated, and a brazed structure with the following structure was produced. For test material No.1-2~1-7, the aluminum alloy brazing plate with the same specifications as test material No.1 of Example 1 is used, and for test material No.5-2, the test material of Example 1 is used Aluminum alloy brazing plate of the same specification as No.5. In addition, for test materials Nos. 1-5 and 5-2, aluminum alloy brazing sheets manufactured by the same method as pipe materials were used for the fin materials. The aluminum alloy brazing sheet for the fin material is made of the same JIS3003 alloy as the aluminum alloy sheet, and the brazing filler metal is the same as that of the test material No. Al-10% Si alloy (see Table 1), the thickness is 0.1mm which is the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com