Furnace hearth set for synthesizing crystals by using flame fusion method

A technology of flame melting method and furnace, which is applied in the field of flame melting synthetic crystal furnace group, which can solve the problems of inconsistent shape, difficult to meet, large transverse temperature and longitudinal temperature gradient, etc., and achieve small longitudinal temperature and transverse temperature gradient and free flow Smooth, defect-less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

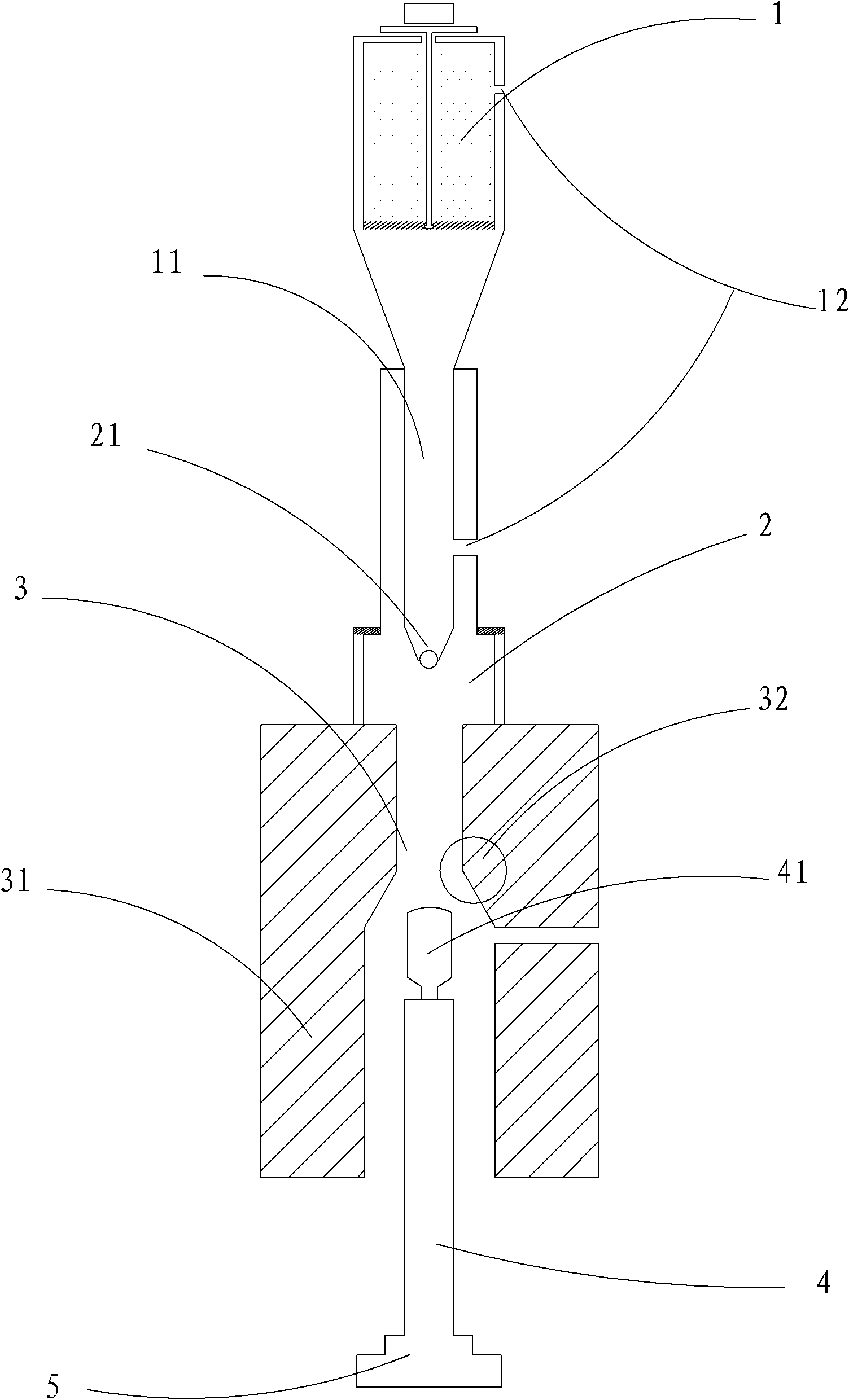

[0025] Please also refer to figure 2 , image 3 and Figure 5 , the embodiment of the furnace group of the flame fusion synthesis crystal of the present invention includes a feeding device 1, a hydrogen supply system 12, a combustion chamber 2, a furnace 3, a supporting column 4 and a lowering mechanism 5, and the shaking and feeding Device 1, so that the powder in the feeding device 1 falls, the powder is y-Al 2 o 3 , by O 2 The powder is sent to the nozzle 21 by the feed pipe 11, and H 2 Mixed combustion in the combustion chamber 2 forms a hydrogen-oxygen flame with powder, enters the furnace 3, and falls on the crystal 41 layer by layer. As the crystal 41 continues to grow, at the same time, the lowering mechanism 5 drops synchronously bit by bit. Within a specified time, the desired crystal 41 grows.

[0026] The outer layer of the furnace 3 is an insulating layer 31, the inner cavity of the furnace 3 is a spindle-shaped curved structure, there is no turning structu...

Embodiment 2

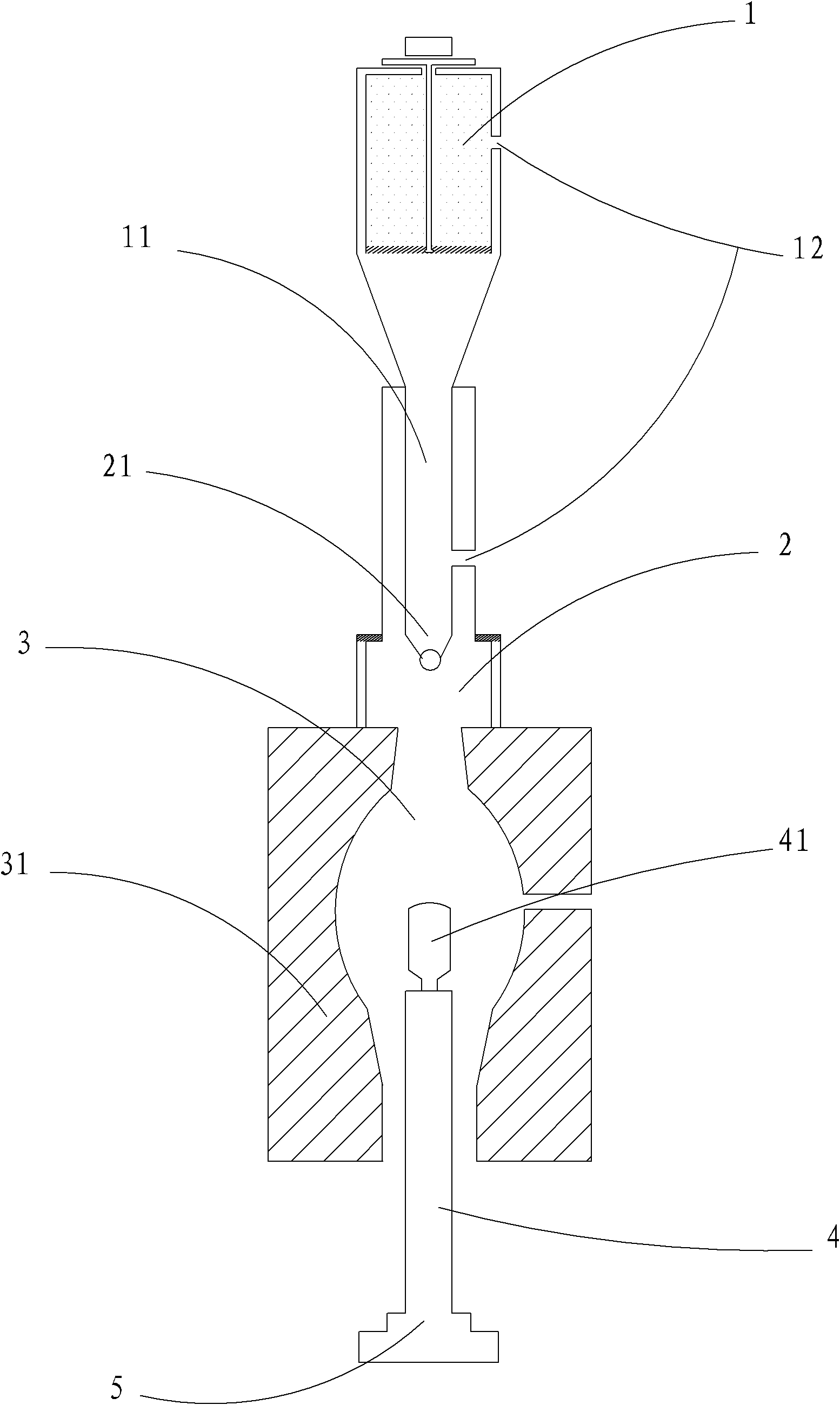

[0037] Please also refer to figure 2 and Figure 4 , this embodiment is improved on the basis of embodiment 1.

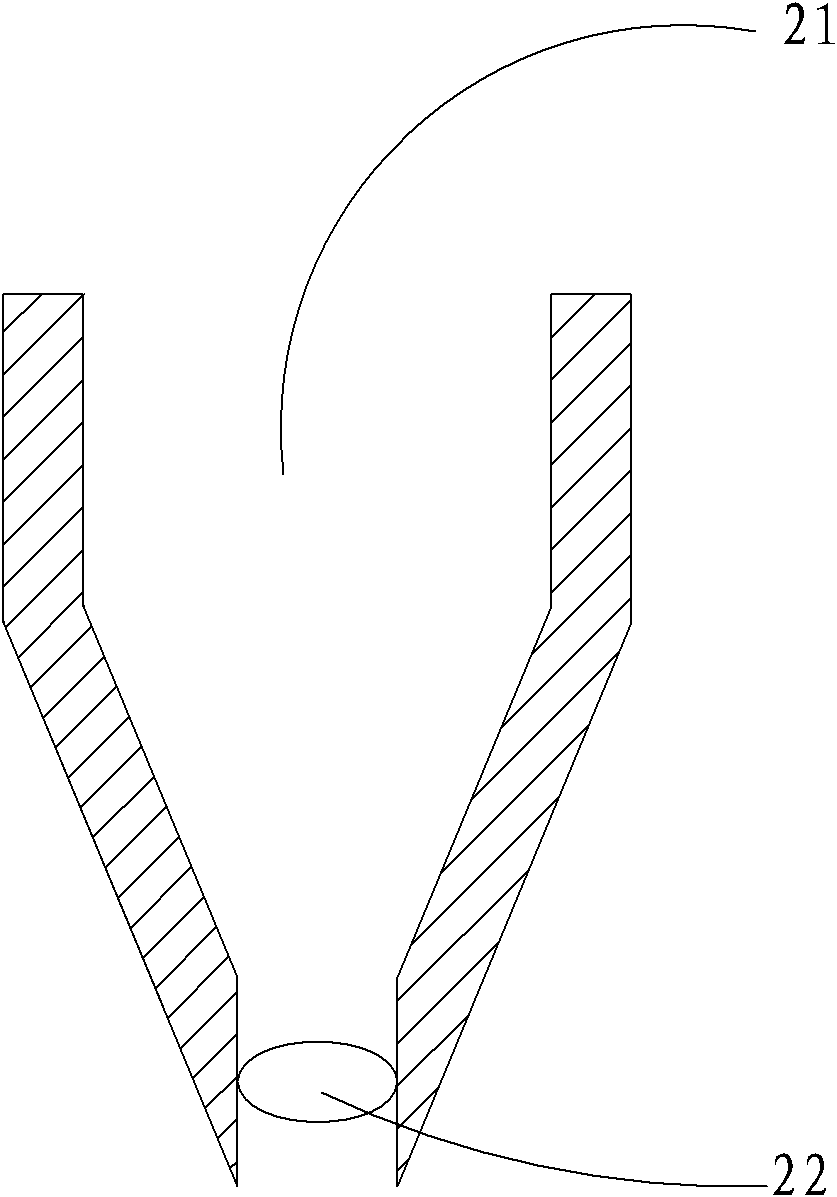

[0038] In this embodiment, the cross section of the inner chamber of the furnace 3 is a circular structure, and the nozzle 22 of the nozzle 21 in the combustion chamber 2 is designed to be a circular structure suitable for the furnace 3 . The inner cavity of the upper port of the furnace has a diameter of 24 mm to 36 mm, the inner cavity of the lower port of the furnace has a diameter of 85 mm to 118 mm, and the inner cavity of the crystallization zone of the furnace has a diameter of 100 mm to 150 mm. The nozzle diameter of the nozzle is 6.5mm~12mm

[0039] Table 3: A list of circular furnace and nozzle structures

[0040]

[0041] According to the furnace hearth 3 and spout 22 of above-mentioned diameter design, be used for the corundum crystal 41 of synthesis, the result of test is as follows table:

[0042] Table 4: Quality grades of round semi-pear crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com