Imaging adjustment unit and focusing and leveling control system using the unit

A technology of adjusting unit and imaging unit, applied in the field of control system, can solve the problem of difficult installation, and achieve the effects of simple design, strong space adaptability, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the technical content of the present invention, specific embodiments are given and described as follows in conjunction with the accompanying drawings.

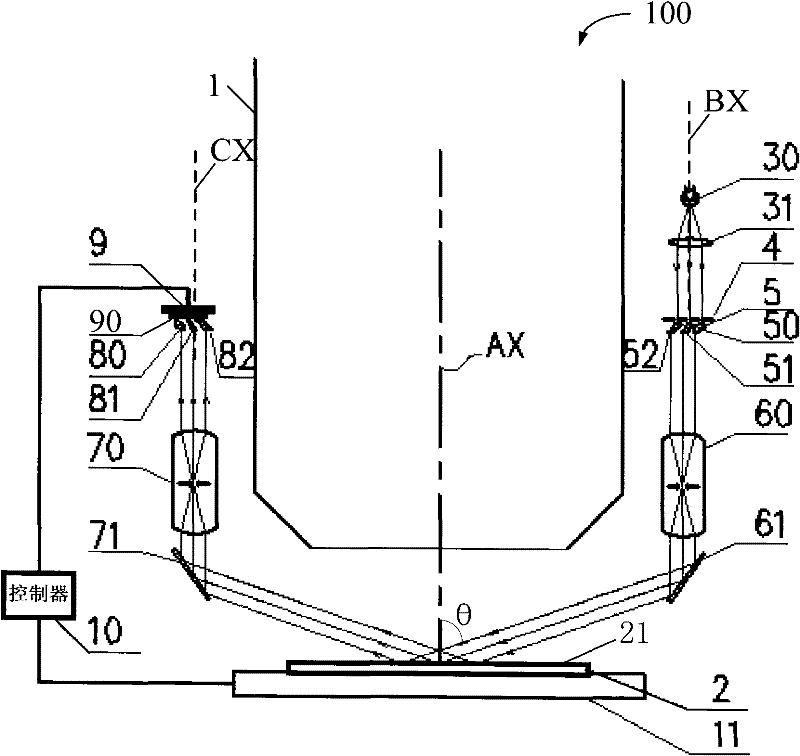

[0022] figure 1 Shown is a schematic structural diagram of the projection lithography machine according to the first embodiment of the present invention.

[0023] Please refer to figure 1 . The projection lithography machine 100 includes a projection objective lens 1 , a silicon wafer 2 and a workpiece stage 11 . The projection objective lens 1 is placed along the first optical axis AX, and is used for performing photolithography on the silicon wafer 2 . The silicon wafer 2 is placed on the workpiece table 11 , the silicon wafer surface 21 of the silicon wafer 2 is perpendicular to the optical axis AX, and the silicon wafer surface 21 is located on the best focal plane of the projection objective lens 1 . The workpiece table 11 is driven by the workpiece table motion system (not shown) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com