Novel separation film and preparation method thereof

A production method and separation membrane technology, applied in the field of separation membrane, can solve the problems of high operating cost of membrane process, membrane fouling, and high price of membrane and membrane equipment, and achieve the effects of good separation performance, simple membrane production process and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

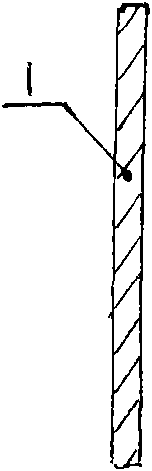

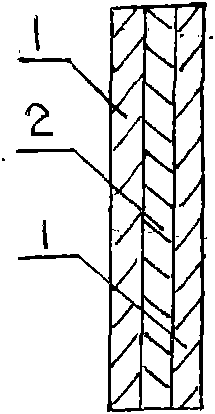

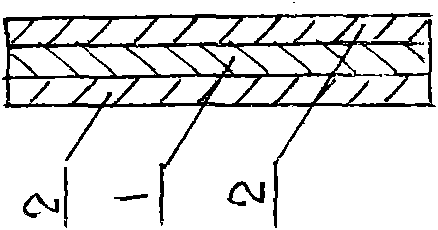

[0025] 1 Single film production method

[0026] (1) Manufacturing method of single hydrophilic membrane:

[0027] Put the selected starch and cellulose in warm clear water to make slurry, filter and evenly brush (or scrape or spray) on a flat plate or columnar cylinder to dry into a starch cellulose film. When the water content of the starch cellulose film drops Microporous hydrophilic membrane can be made by irradiating it with microwave (or infrared ray, ultrasonic wave) to make it puff up to 5%--30%.

[0028] (2) Method for making a single hydrophobic membrane

[0029] Homogenize raw egg whites at room temperature, filter and evenly brush (or scrape, spray) on a flat plate or columnar cylinder to make it into a protein film. When the water content drops to 5% - 30%, use Microporous hydrophobic membrane can be made by irradiating it with microwaves (infrared rays, ultrasonic waves) to make it thermally deformed and expanded.

[0030] 2. The production method of enhanced m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com