Reparation method of tungsten titanium alloy target material used in semiconductor and solar sputtering target material industries

A tungsten-titanium alloy and sputtering target technology, applied in the field of material processing, can solve the problems of easy oxidation, uneven mixing of tungsten-titanium alloy powder, and high impurity content, so as to improve high-temperature compressive strength, maintain purity, and reduce oxygen content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

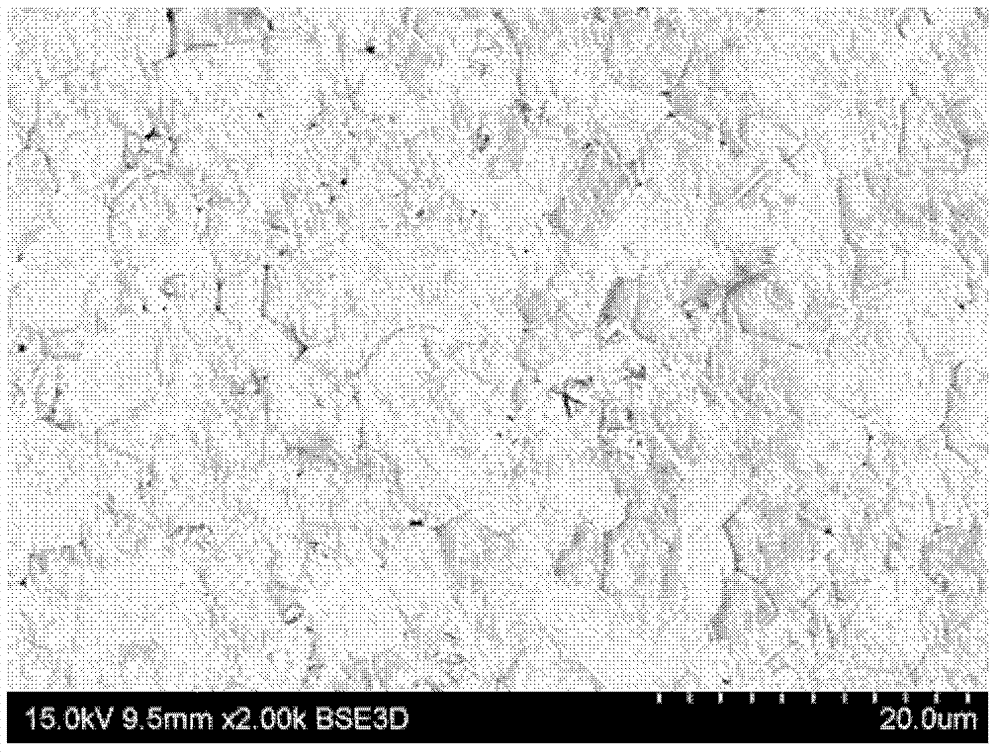

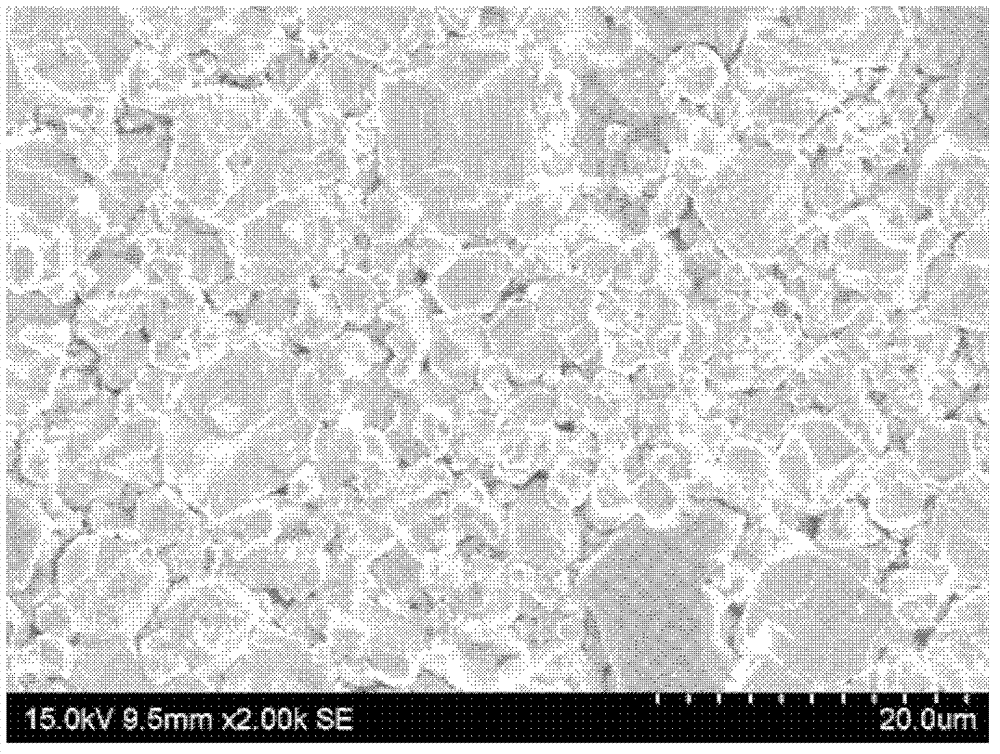

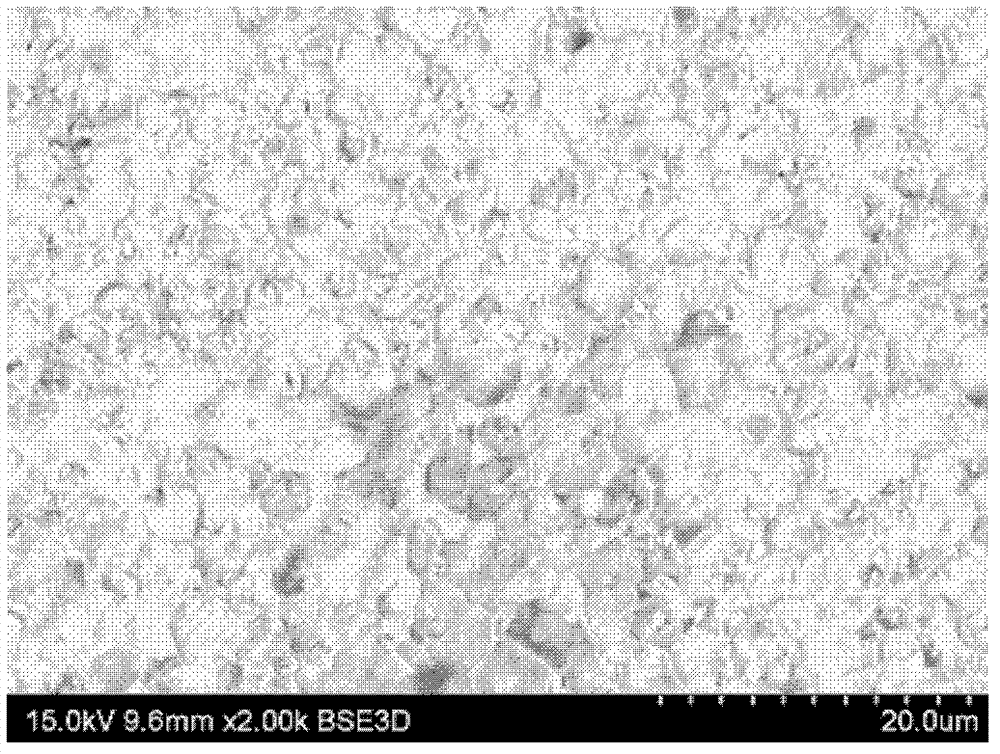

Image

Examples

Embodiment 1

[0029] Embodiment 1, a method for preparing a tungsten-titanium alloy target for semiconductor and solar sputtering target industries of the present invention includes the following steps:

[0030] a. Tungsten powder with a Fischer mean particle size of 2.8 μm, titanium powder with a Fischer mean particle size of 60 μm, and titanium hydride powder with a Fischer mean particle size of 60 μm, according to tungsten powder: titanium powder: titanium hydride powder is 7.0: 1.5: The mass ratio of 1.5 is placed in a three-dimensional mixer, and mixed for 1.5 hours at a speed of 70r / min to obtain tungsten-titanium alloy powder;

[0031] Wherein, the purity of the tungsten powder is ≥99.995%, and the purity of the titanium powder is ≥99.00%. , the purity of the titanium hydride powder is ≥99.00%;

[0032] b. Place the above-mentioned tungsten-titanium alloy powder in a vacuum hot-pressing sintering mold, compact the powder with a stainless steel plate, and allow it to fully fill the m...

Embodiment 2

[0040] Embodiment 2, a method for preparing a tungsten-titanium alloy target for semiconductor and solar sputtering target industries of the present invention includes the following steps:

[0041] a. The tungsten powder whose average Fischer particle size is 2.0 μm, the titanium powder whose average Fischer particle size is 40 μm, and the titanium hydride powder whose average Fischer particle size is 40 μm are 8.0: 0.5 according to tungsten powder: titanium powder: titanium hydride powder: The mass ratio of 1.0 is placed in a three-dimensional mixer, and mixed for 1.5 hours at a speed of 50r / min to obtain tungsten-titanium alloy powder;

[0042] Wherein, the purity of the tungsten powder is ≥99.995%, and the purity of the titanium powder is ≥99.00%. , the purity of the titanium hydride powder is ≥99.00%;

[0043] b. Place the above-mentioned tungsten-titanium alloy powder in a vacuum hot-pressing sintering mold, compact the powder with a stainless steel plate, and allow it t...

Embodiment 3

[0051] Embodiment 3, a method for preparing a tungsten-titanium alloy target for semiconductor and solar sputtering target industries of the present invention includes the following steps:

[0052] a. Tungsten powder with a Fibonacci average particle size of 1.0 μm, titanium powder with a Fibonacci average particle size of 50 μm and titanium hydride powder with a Fibonacci average particle size of 20 μm, according to tungsten powder: titanium powder: titanium hydride powder is 9.0: 1.0: The mass ratio of 0.5 is placed in a three-dimensional mixer, and mixed for 1.0h at a speed of 40r / min to obtain tungsten-titanium alloy powder;

[0053] Wherein, the purity of the tungsten powder is ≥99.995%, and the purity of the titanium powder is ≥99.00%. , the purity of the titanium hydride powder is ≥99.00%;

[0054] b. Place the above-mentioned tungsten-titanium alloy powder in a vacuum hot-pressing sintering mold, compact the powder with a stainless steel plate, and allow it to fully f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com