Double-delta wing type static mixer and gas mixing method

A technology of static mixer and static mixing device, which is applied in the direction of chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of flow field deterioration, serious dust accumulation, and increased system resistance, so as to achieve low smoke resistance, Retrofit costs are low and the effect of reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

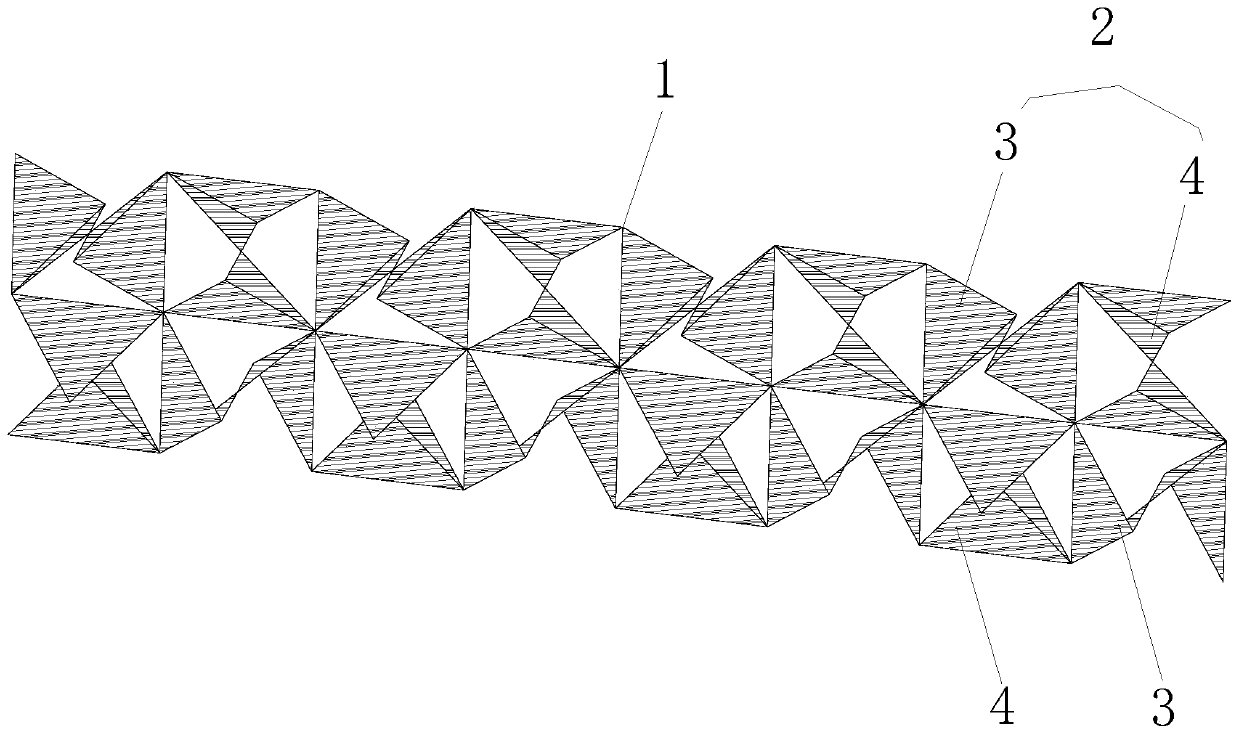

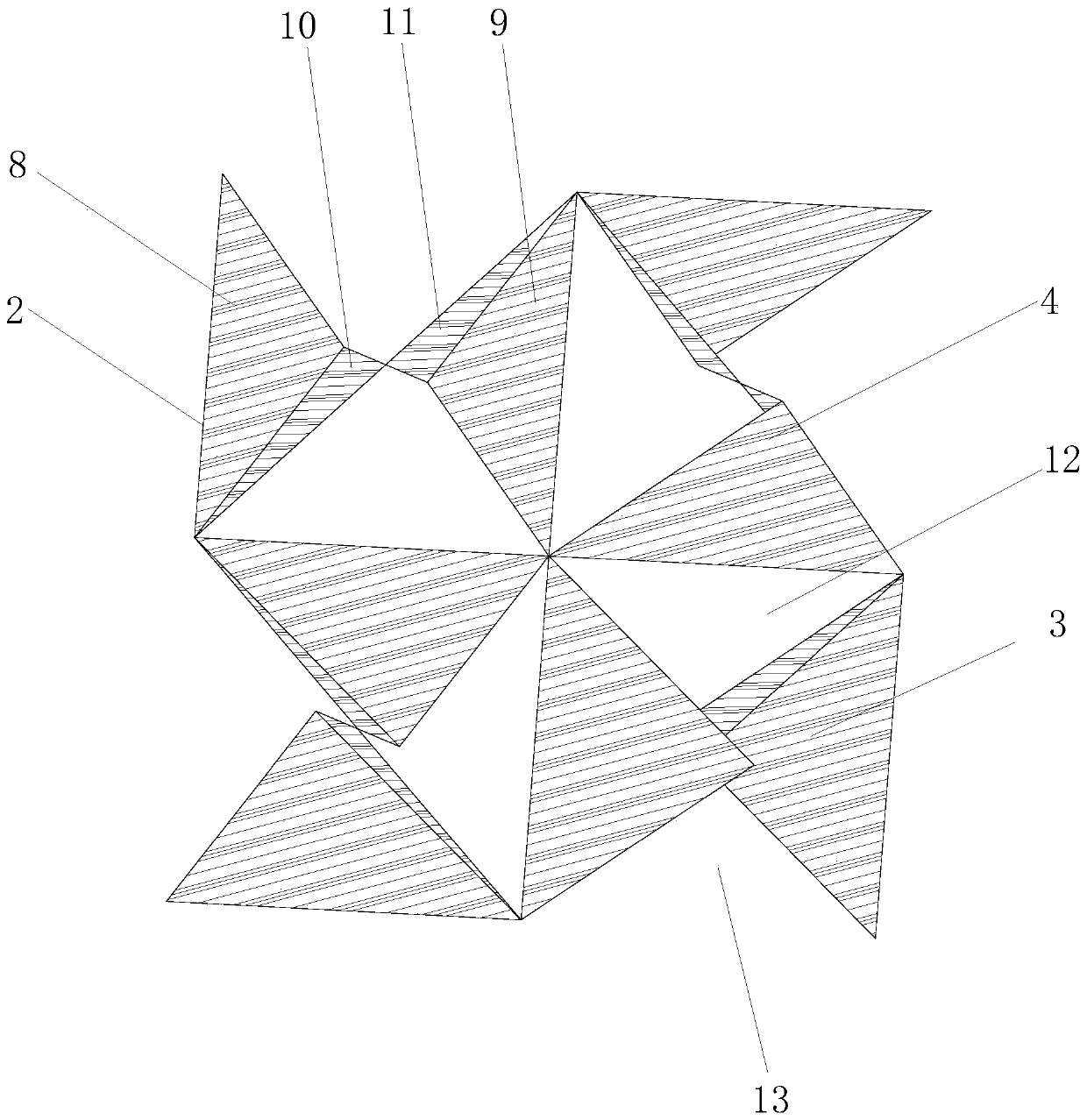

[0034] Embodiment 1 of the present invention: a double-delta airfoil static mixer comprises a group of static mixing devices 1, the static mixing device 1 includes at least one double-delta airfoil mixing unit 2, and the double-delta airfoil mixing unit 2 includes two The horizontally arranged mixing monomer 3 and the two vertically arranged mixing monomers 4, the two horizontally arranged mixing monomers 3 are arranged symmetrically with the first diagonal line 5, and the two vertically arranged mixing monomers 4 are arranged in a second pair The corner lines 6 are arranged symmetrically, and the tips of the two horizontally arranged mixed monomers 3) and the two vertically arranged mixed monomers 4 meet at one point.

Embodiment 2

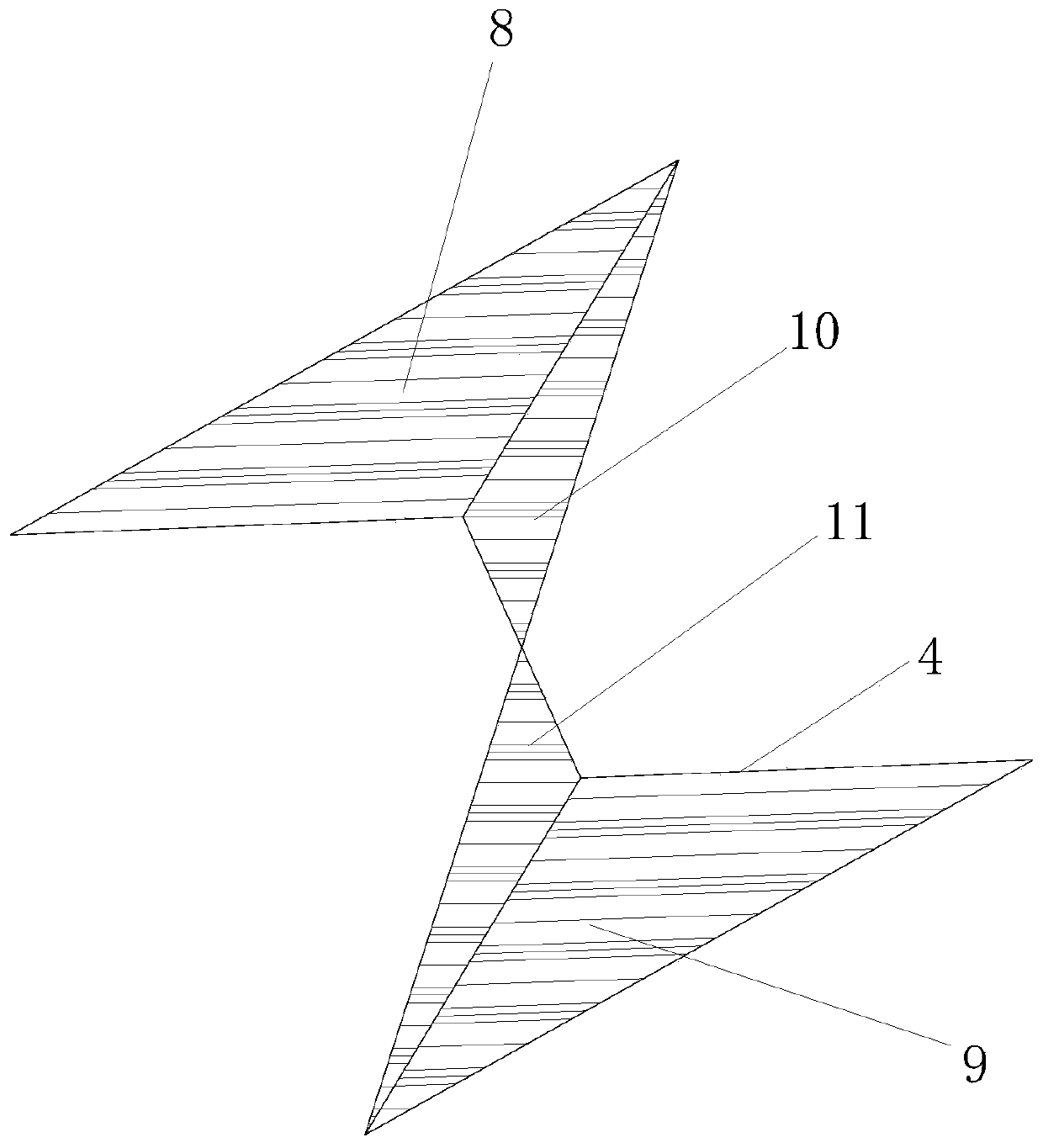

[0035] Embodiment 2 of the present invention: a double delta airfoil static mixer, including two sets of static mixing devices 1, both of which are installed in the flue of the out-of-stock system. Static mixing device 1 comprises at least one double delta wing type mixing unit 2, double delta wing type mixing unit 2 comprises two horizontally arranged mixing cells 3 and two vertically arranged mixing cells 4, two horizontally arranged mixing cells The body 3 is symmetrically arranged on the first diagonal line 5, and the two longitudinally arranged mixed monomers 4 are arranged symmetrically on the second diagonal line 6, and the two horizontally arranged mixed monomers 3 and the two vertically arranged mixed monomers 4 A tip of each meets at one point. Two horizontally arranged mixing cells 3 and two vertically arranged mixing cells 4 all include rectifying blades 7, first rotating blades 8 and second rotating blades 9, one side of the first rotating blade 8 and one side of ...

Embodiment 3

[0036] Embodiment 3 of the present invention: a kind of double delta airfoil static mixer, comprises a group of static mixing device 1, and static mixing device 1 comprises four double delta airfoil mixing units 2, four double delta airfoil mixing units successively connect. The double delta airfoil mixing unit 2 includes two horizontally arranged mixing cells 3 and two vertically arranged mixing cells 4, the two horizontally arranged mixing cells 3 are symmetrically arranged on the first diagonal line 5, and the two vertically arranged The arranged mixing units 4 are arranged symmetrically with respect to the second diagonal line 6 , and the tips of the two horizontally arranged mixing units 3 and the two vertically arranged mixing units 4 meet at one point. Two horizontally arranged mixing cells 3 and two vertically arranged mixing cells 4 all include rectifying blades 7, first rotating blades 8 and second rotating blades 9, one side of the first rotating blade 8 and one sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com