Glass wool pulping device with guide spirals inside

A glass wool and spiral technology, applied in synthetic cellulose/non-cellulose material pulp/paper, fiber raw material processing, textile and papermaking, etc. Increase the dispersibility and improve the effect of uneven mixing of the slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

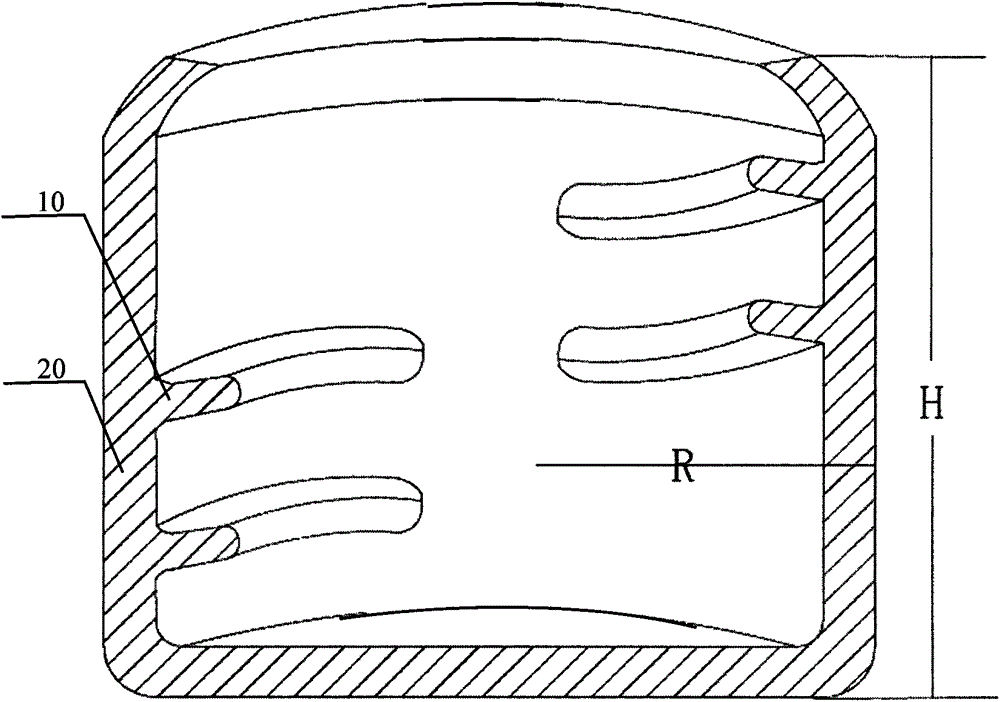

[0030] The pre-customized segmented material guide screw 20 is welded to the inner wall of the box body 10, referring to Figure (1) and Figure (2), a kind of spiral glass wool beating device and method described in this embodiment are as follows:

[0031] The inner diameter of the existing glass wool beater casing 10 is R=0.9m, and the axial height is H=1.5m.

[0032] The distance between the starting end of the material guide screw 20 and the two ends of the casing is limited to be 18 cm, and the helix angle of the material guide screw 20 is 15°.

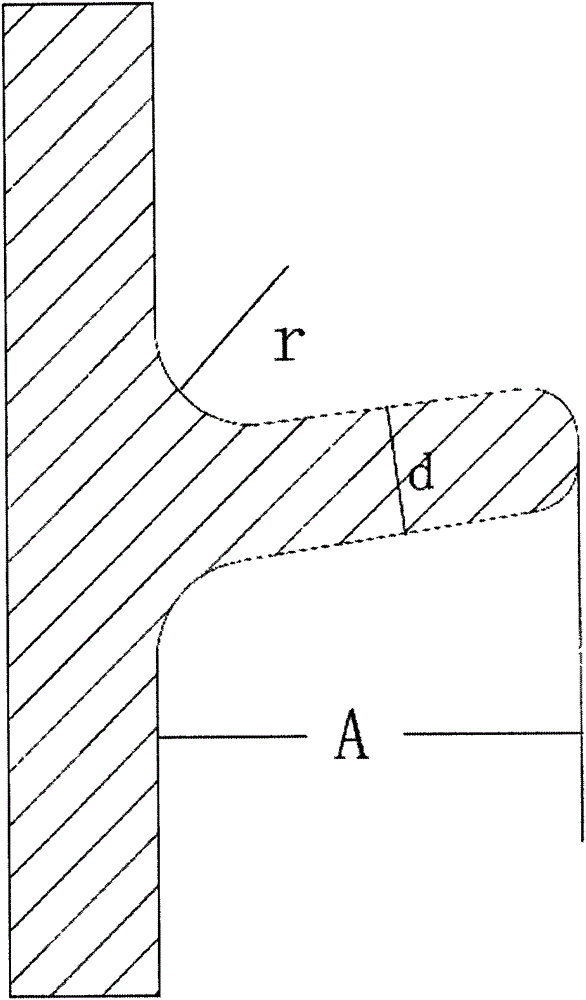

[0033] For the cross-section of the material guide screw 20, as shown in Figure (2), the inner diameter of the transition fillet is r=6cm, the width A of the raised part is 15cm, and the average thickness d is 8cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com