A method for preparing graphene-based composites based on graphene oxide self-assembly

A graphene-based, composite material technology, applied in the preparation of amino hydroxyl compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the limitations of functional modification of material properties, poor water dispersibility of graphene-based composite materials, aggregation, etc. problem, to achieve the effect of long-lasting chemical stability and catalytic activity, good application potential, and simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

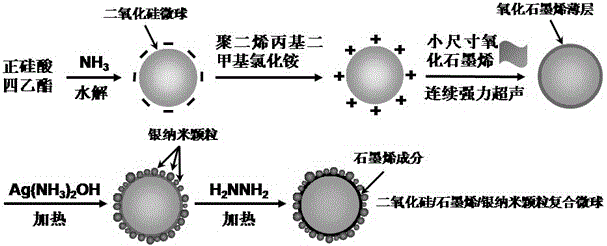

[0035] Embodiment 1: The method provided by the invention is used for the assembly of small-sized graphene oxide sheets on the surface of silica microspheres:

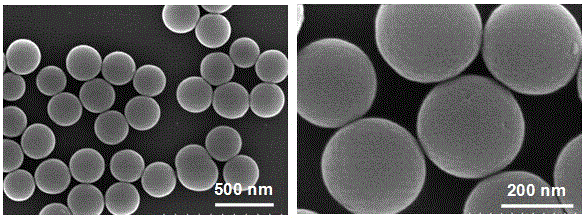

[0036] (1) Mix 100 mL of 0.2 M tetraethyl orthosilicate ethanol solution with 100 mL of ethanol solution containing ammonia (1.6 M) and water (34 M), and stir vigorously overnight. Using ethanol as a solvent, the silica colloidal microspheres generated by the hydrolysis of tetraethylorthosilicate under the catalysis of ammonia were centrifuged repeatedly — Vacuum dry after washing. The as-prepared silica colloidal microspheres were quite uniform in size, with an average diameter of ~280 nm ( figure 2 ).

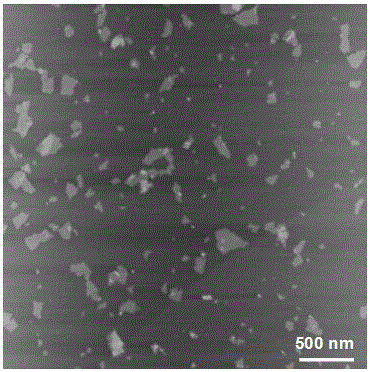

[0037] (2) Ultrasonic disperse 1 g of the silica microspheres prepared in step (1) in 100 mL of water to form a 10 mg / mL aqueous dispersion; Dimethylammonium chloride was dissolved in 95 mL of water and stirred for more than 1 h. Then mix the silica aqueous dispersion with the polydiallyldimethylammonium chloride...

Embodiment 2

[0044] Embodiment 2: the method provided by the invention is used to prepare the graphene-based composite material with unique structure and high water dispersibility:

[0045] (1) Ultrasonic disperse 0.4 g of the silica / graphene oxide composite microspheres in Example 1 in 100 mL of water to form an aqueous dispersion with a concentration of 4 mg / mL, and mix it with 100 mL of 40 mM Stir and mix the newly prepared silver ammonia solution at 85 o C for 45 min, using the reducing property of graphene oxide itself to reduce the silver ammonium complex into silver nanoparticles in situ and deposit them on the surface of the composite microspheres to prepare a composite of silica / graphene oxide / silver nanoparticles Microspheres. Using water as solvent, it was centrifuged repeatedly — Vacuum dry after washing.

[0046] (2) Ultrasonic disperse 0.2 g of the silica / graphene oxide / silver nanoparticle composite microspheres in step (1) in 100 mL of water to form an aqueous dispersion ...

Embodiment 3

[0052] Embodiment 3: the graphene-based composite material prepared in the present invention is used for the catalytic reduction of 4-nitrophenol:

[0053] (1) Weigh 3 mg of the silica / graphene / silver nanoparticle composite microspheres in Example 2, and ultrasonically disperse them in 20 mL of water to form an aqueous dispersion with a concentration of 0.15 mg / mL, and take 1 mL, and then diluted to an aqueous dispersion with a concentration of 1.5 μg / mL.

[0054] (2) Take 1 mL of the aqueous dispersion diluted in step (1), and mix it successively with 1 mL of 30 mM sodium borohydride aqueous solution and 1 mL of 0.3 mM 4-nitrophenol aqueous solution , and then transfer the reaction mixture to a cuvette for reaction.

[0055] (3) The whole process of the catalytic reaction adopts ultraviolet — Visible spectroscopy was used for in situ monitoring to determine the rate constant of this reaction and to identify the catalytic activity of the as-prepared catalyst (ie, silica / grap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com