Preparation method of polymerization-inhibiting coating for aromatic olefin monomer

A technology for aromatic olefins and coatings, which is applied in the field of preparation of polymerization inhibitor coatings, and can solve the problem that there is no report on the specific method of the release rate of polymerization inhibitor coating adhesion change, no disclosure of coating preparation process conditions, brushing Problems such as many steps, to achieve the effect of prolonging the period of maintenance and cleaning tanks, eliminating product pollution, and reducing the amount of coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0029] Embodiment 1~5: coating surface layer base material preparation

[0030]In a 1L reactor with a stirrer and a reflux condenser, add 400g of EP828 epoxy resin and 100g of glycidyl ether additive, and heat up under nitrogen atmosphere to prepare the base material for the coating surface layer; The pulp amine adduct curing agent is added to the prepared base material for stirring, wherein the mixing ratio of base material and thick pulp amine adduct is 6:1 (volume ratio), and the stirring time is 0.3h. Then paint the above-mentioned epoxy resin paint on the standard tin plate (50×100×0.2~0.3mm), and the thickness of the coating is about 100 μm. After the coating was dry, the adhesion was tested, and the test results under different reaction conditions are shown in Table 1.

[0031] Table 1 Preparation conditions of coating surface layer base material

[0032] Example

[0033] It can be seen from Table 1 that the coating materials prepared by the above methods ca...

Embodiment 6~16

[0034] Embodiment 6~16: the base material preparation of coating bottom layer (preparation of base material for polymerization inhibition coating)

[0035] After the reaction as described in Example 3 is completed, lower the temperature to 50-90°C, continue to stir, add one or two compound polymerization inhibitors to the system, and keep warm for 1-3 hours to obtain coatings with different polymerization inhibition properties Binder. Similarly, before painting, add the thickener amine adduct curing agent to the above-mentioned base material for stirring, wherein the mixing ratio of the base material and the thicker amine adduct is 8:1 (volume ratio), and the stirring time is 1h. Then paint the above material on the standard tinplate plate (50×100×0.2~0.3mm), and the coating thickness is about 80 μm. After the coating dries up, the adhesion is tested, and the results are shown in Table 2:

[0036] Table 2 Preparation conditions of polymerization inhibition coating base mater...

Embodiment 17~20

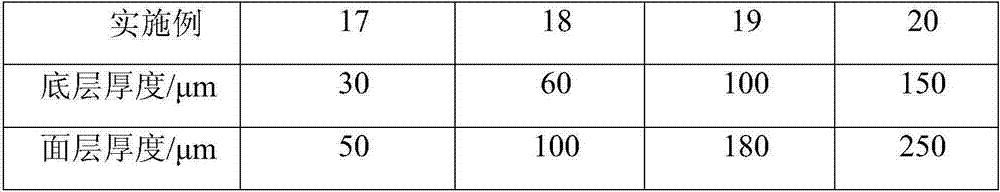

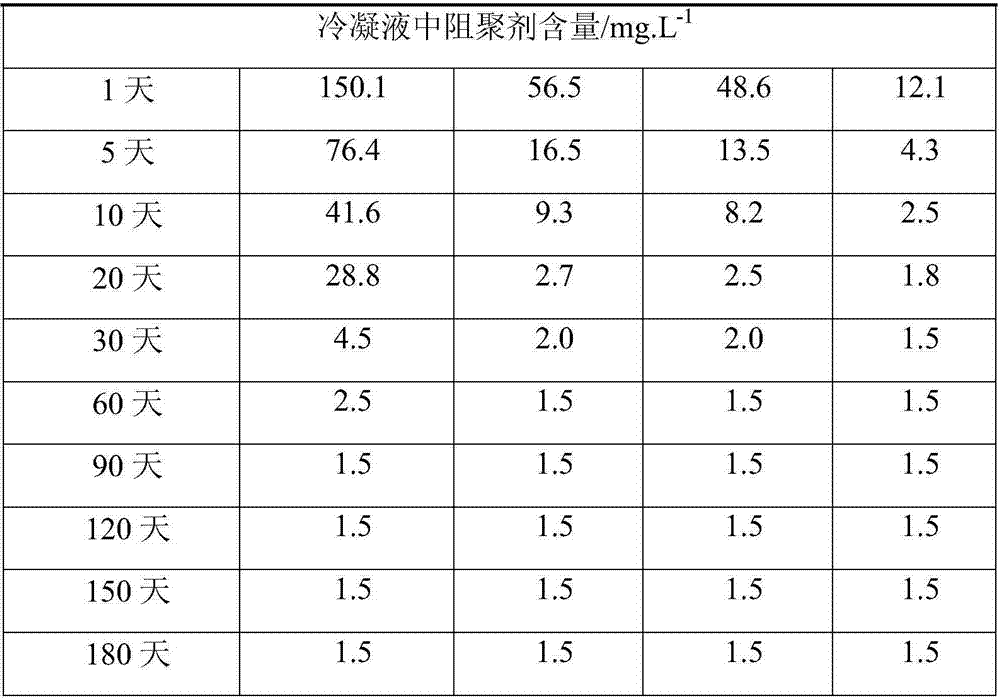

[0041] Examples 17-20: Investigation of the polymerization inhibition effect of the polymerization inhibition coating

[0042] Brush epoxy resin paint on the inner wall of the tank roof of 5L styrene storage tank. The preparation method of epoxy resin paint is as follows: In a 1L reactor with agitator and reflux condenser, add 500g of EP828 epoxy resin, shrink 120g of glycerol ether additive, purged with nitrogen for 10 minutes, started stirring, heated up to 170°C, reacted for 2 hours, cooled down to 60°C, and took out about half of the reactants for use. Then add the composite polymerization inhibitor TBBQ+HPHA to the system, the addition amount is 27% of the amount of reactants, the compounding mass ratio of TBBQ and HPHA is 3:1, and keep warm for 2 hours at 60°C to obtain a coating with polymerization inhibition performance. layer base.

[0043] The roof of the styrene storage tank is painted with two layers of overcoating, in which the mixing ratio of the base material a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com