Implementation method for self-starting and stopping control system of machine set

A technology of a control system and an implementation method, applied in the direction of program control, electrical program control, etc. in a sequence/logic controller, can solve the problems of increased debugging workload, increased configuration and debugging work, inflexibility, etc. The effect of thermal control automation level, improving debugging efficiency and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

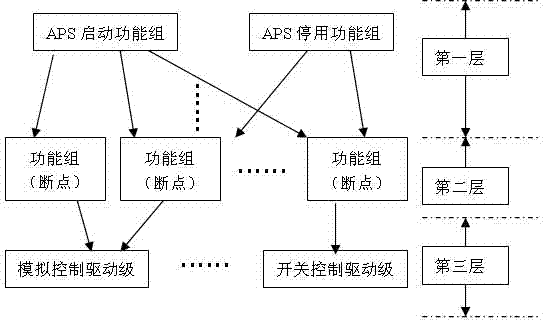

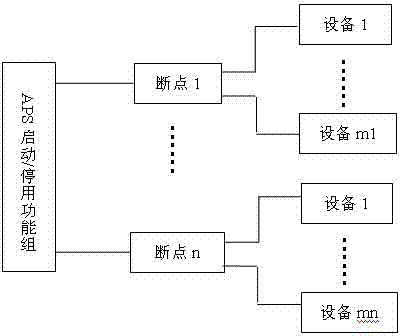

[0025] The invention provides a programming method to realize the APS function. The specific scheme is as follows: on the basis of the original third layer of APS, that is, the device driver level or part of the sequential control function group, the third layer configuration content is not changed, and the second layer breakpoint layer and the first layer APS function are realized by programming. Group functions.

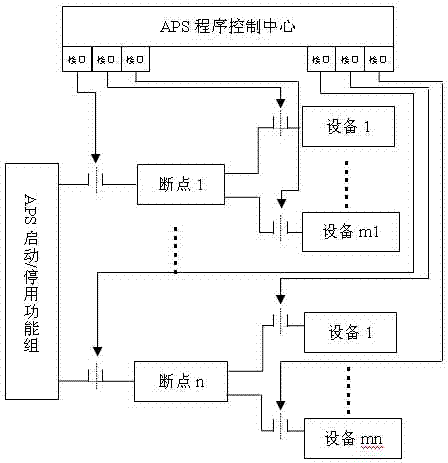

[0026] like image 3 As shown, the content of the invention is the APS program control center in the box, which is realized by programming, without adding actual configuration, and directly uses the program instead of the operator to issue instructions to complete the function. figure 1 The methods implemented in the first layer and the second layer are similar, but the calling objects are different.

[0027] The method for realizing the self-starting and stopping control system of the unit provided by the present invention uses the APS program control center to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com