Method for producing a molded part provided with a through hole

A technology for molded parts and equipment, applied in the direction of mechanical equipment, engine components, etc., can solve problems such as deformation, burrs, and artificial damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following embodiments describe only the production of, for example, planar annular molded parts, using bars or blanks with a circular cross section.

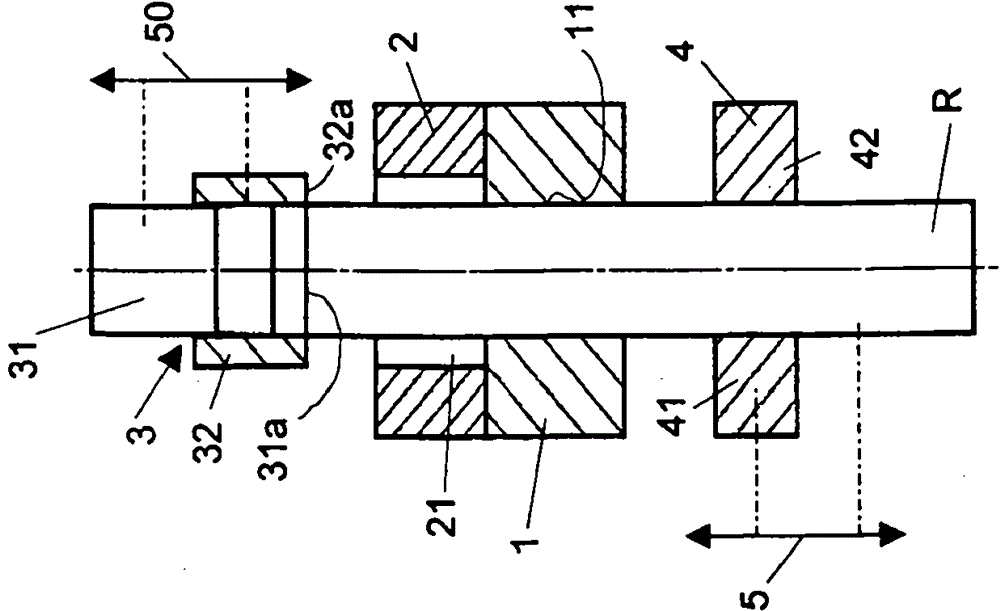

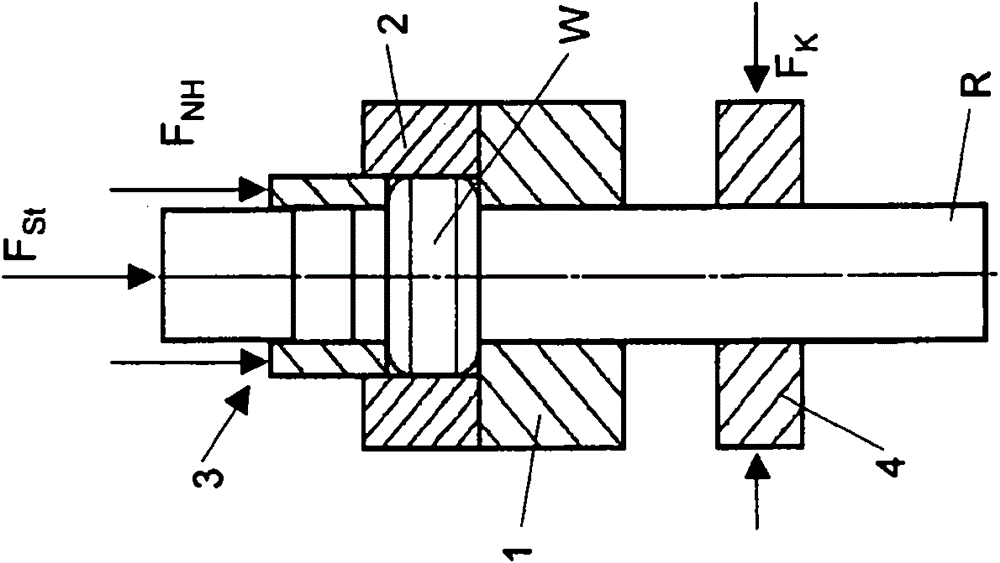

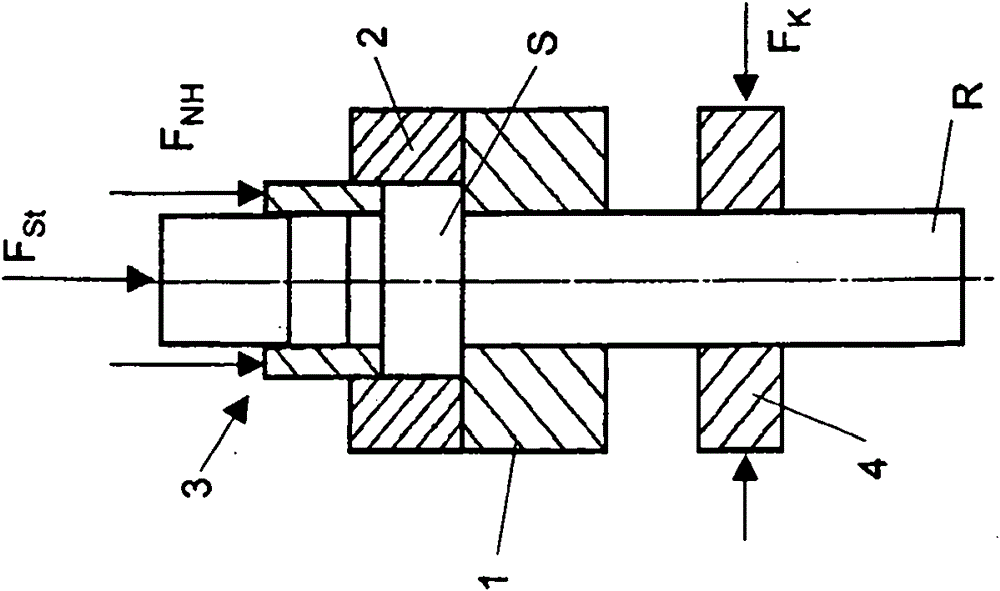

[0029] Figure 1-6 A first embodiment of the invention is described, in which only the essential parts of the device for understanding the invention are shown. A guide 1, a die 2 arranged above it, a die 3 and a clamping device 4 as well as the feed devices 5 and 50, symbolized only by an arrow, can be seen for a Cross-sectional rod-shaped blank R for the clamping device 4 and for the die 3 . The guide 1 , the die 2 , the die 3 and the clamping device 4 are positioned concentrically with one another. The die 3 comprises a punch 31 and a substantially sleeve-shaped or annular hold-down device 32 surrounding the punch. The guide 1 and the die 2 are fixed, while the die 3 and the clamping device 4 are axially movable. The guide device 1, the die 2, the die 3, the clamping device 4 and the feed device 5, 50 are parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com