Coal sample transfer system

A coal sample and sample loading technology, which is applied in the field of material transportation and management equipment, can solve the problems of low production efficiency, large staffing, and low degree of automation, and achieve the effects of saving storage space, simplifying storage methods, and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

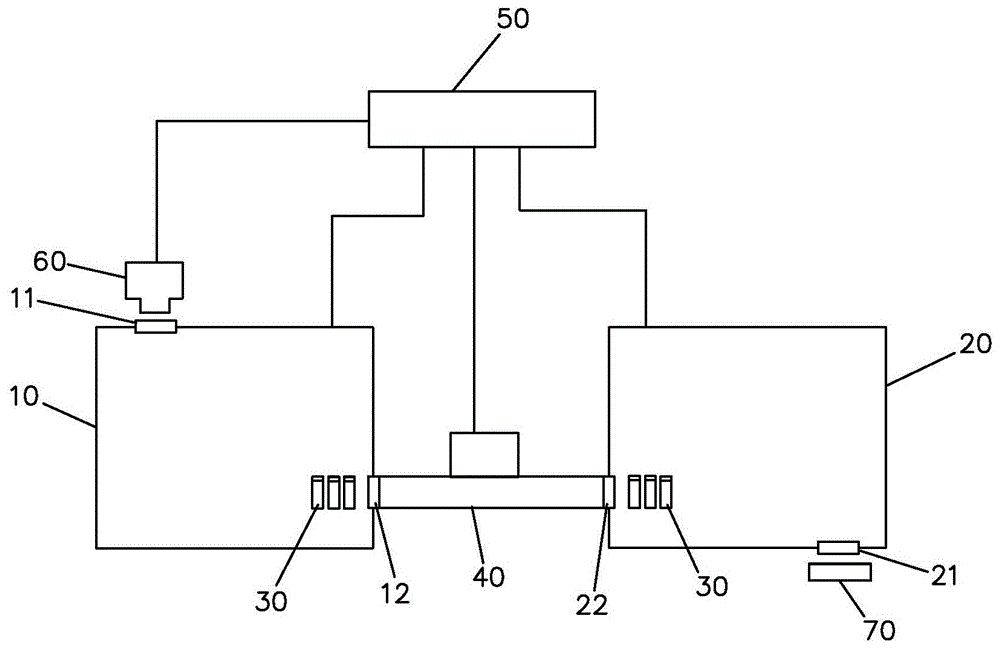

[0019] Such as figure 1 As shown, the coal sample transfer system provided in this embodiment includes a packaging machine 10 , an unloading machine 20 , a container 30 , a conveying device 40 and a control device 50 . The container 30 is used for loading coal samples, and has a bottle body (tank body) and a cover.

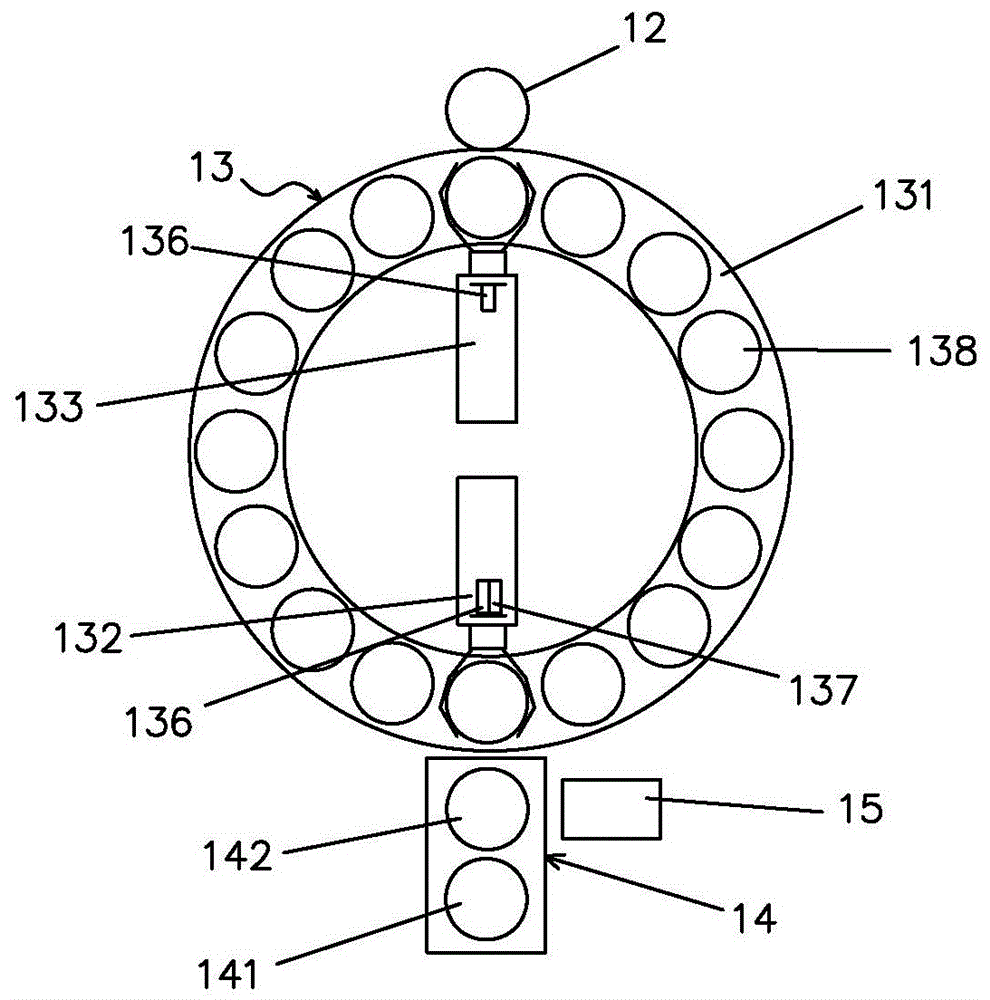

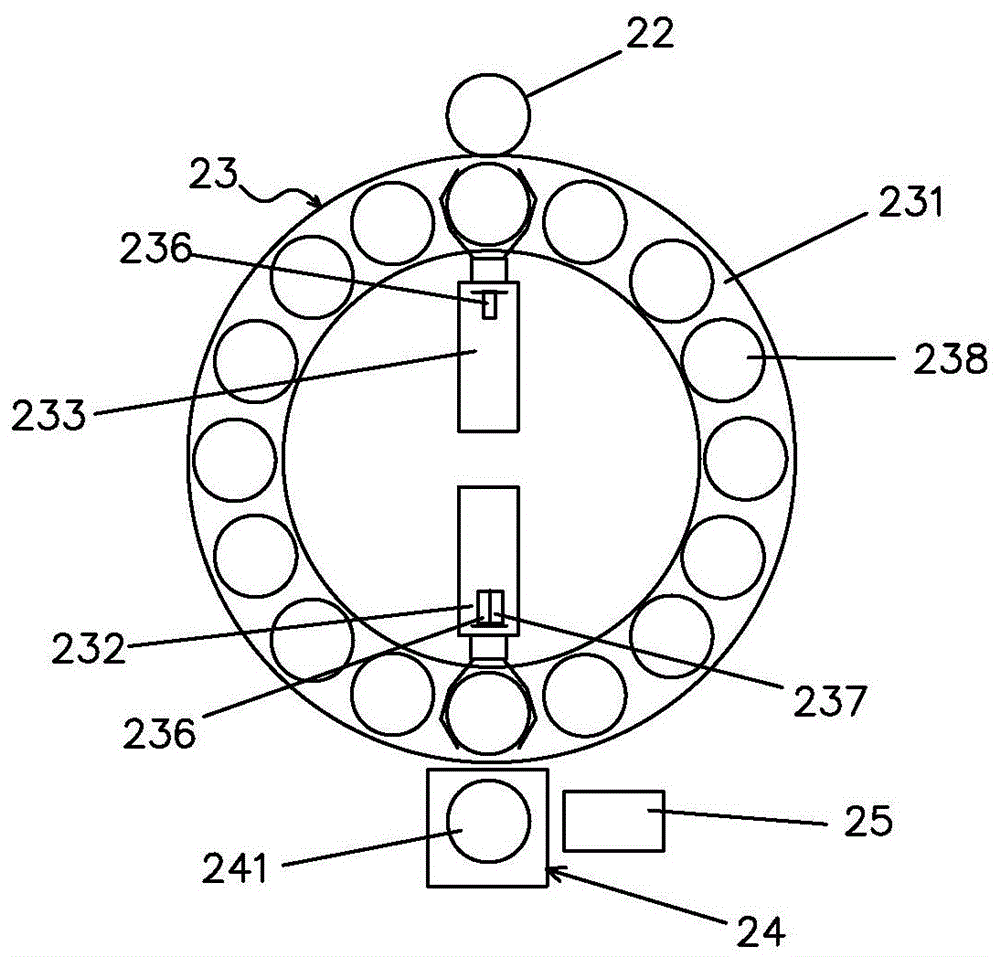

[0020] The packaging machine 10 is used to receive empty containers 30 , perform sample loading and packaging, and then transfer to the unloading machine 20 . The packaging machine 10 has a frame type or a semi-closed frame, and a material receiving port 11 and a container inlet and outlet 12 are arranged on the frame. A quantitative feeder 60 is provided at the material receiving port 11 , and the feeder 60 is used for loading coal samples into the container 30 located in the material receiving port 11 . The container inlet and outlet 12 is a mouth for the container 30 to come in and out, and the container inlet and outlet 12 cooperates with the conveying devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com