Biomass resin

A biomass and resin technology, applied in cellulose derivative binders, binder types, binder additives, etc., to simplify the application, expand the application space, and achieve the effect of full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

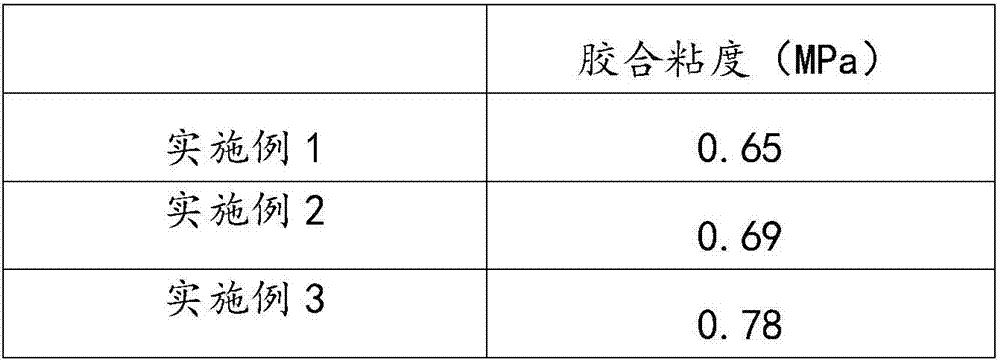

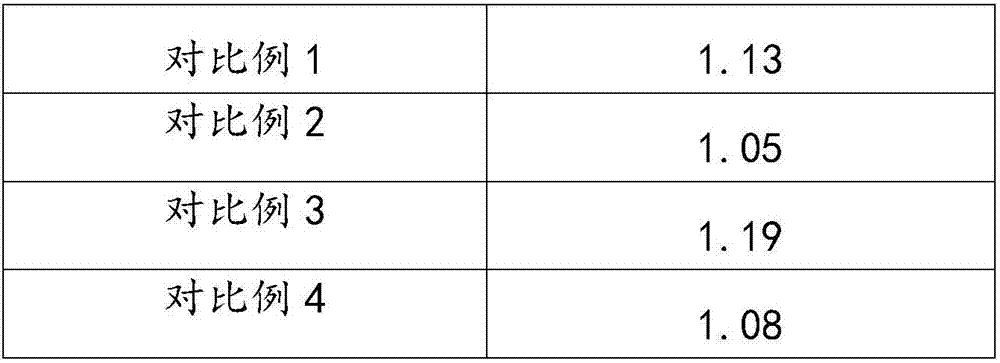

Embodiment 1

[0020] A biomass resin, consisting of the following components by weight: 6 parts by weight of composite stabilizer, 21 parts by weight of modified plant cellulose, 42 parts by weight of plant starch, 4-10 parts by weight of vegetable protein powder, compound enzyme 4 parts by weight of preparation, 14 parts by weight of resin additive, 3 parts by weight of defoamer and 3 parts by weight of preservative.

Embodiment 2

[0022] A biomass resin, consisting of the following components by weight: 5 parts by weight of a composite stabilizer, 18 parts by weight of a modified plant cellulose, 40 parts by weight of a plant starch, 5 parts by weight of a vegetable protein powder, and 4 parts by weight of a compound enzyme preparation parts by weight, 14 parts by weight of resin auxiliary agent, 3 parts by weight of defoamer and 3 parts by weight of preservative.

Embodiment 3

[0024] A biomass resin, consisting of the following components by weight: 8 parts by weight of a composite stabilizer, 25 parts by weight of a modified plant cellulose, 33 parts by weight of a plant starch, 5 parts by weight of a vegetable protein powder, and 4 parts by weight of a compound enzyme preparation parts by weight, 12 parts by weight of resin additives, 3 parts by weight of defoamer and 3 parts by weight of preservative.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com