Novel biomass resin

A biomass and resin technology, used in adhesive types, starch-derived adhesives, adhesive additives, etc., to reduce raw material waste and processing costs, reduce viscosity, and increase solid content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

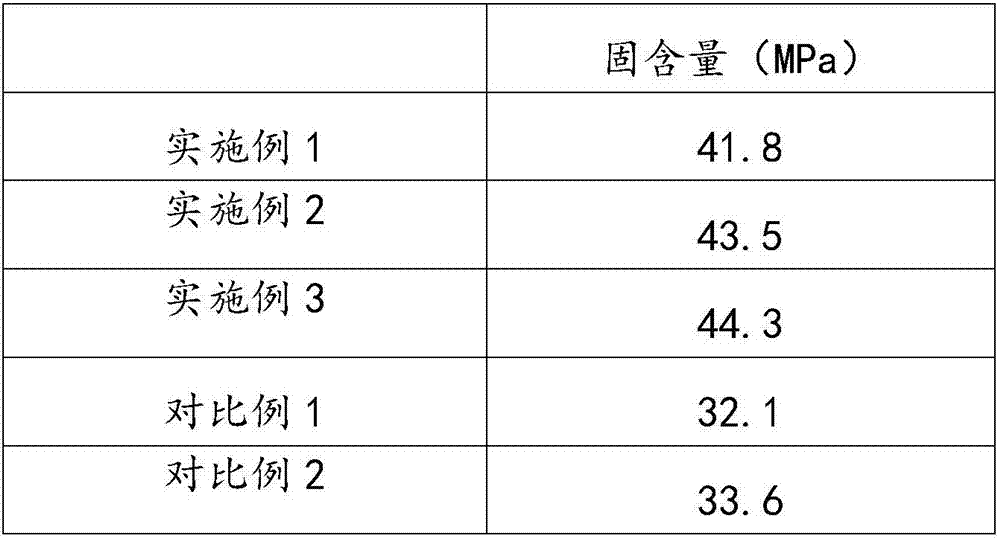

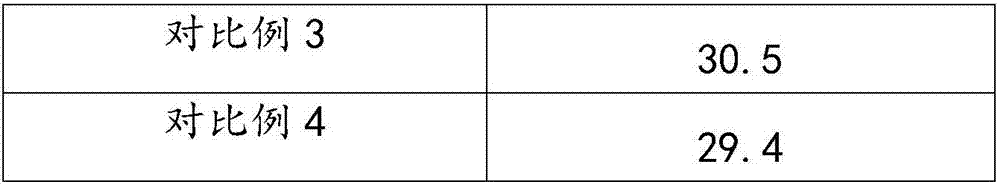

Embodiment 1

[0020] A novel biomass resin, consisting of the following components in parts by weight: 8 parts by weight of resin powder, 25 parts by weight of modified cellulose, 38 parts by weight of modified starch, 4 parts by weight of protein powder, and 6 parts by weight of compound enzyme preparation , 10 parts by weight of resin auxiliary agent, 8 parts by weight of modifier and 3 parts by weight of preservative.

Embodiment 2

[0022] A new type of biomass resin, consisting of the following components in parts by weight: 6 parts by weight of resin powder, 25 parts by weight of modified cellulose, 30 parts by weight of modified starch, 4 parts by weight of protein powder, and 6 parts by weight of compound enzyme preparation , 12 parts by weight of resin auxiliary agent, 8 parts by weight of modifier and 3 parts by weight of preservative.

Embodiment 3

[0024] A novel biomass resin, consisting of the following components in parts by weight: 10 parts by weight of resin powder, 20 parts by weight of modified cellulose, 42 parts by weight of modified starch, 4 parts by weight of protein powder, and 6 parts by weight of compound enzyme preparation , 12 parts by weight of resin additive, 6 parts by weight of modifier and 3 parts by weight of preservative.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com