Ultrasonic measurement device and ultrasonic measurement method

An ultrasonic and measurement technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, measuring devices, and material analysis using sonic/ultrasonic/infrasonic waves, etc. Resolution and other issues, to achieve the effect of improving the measurement resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

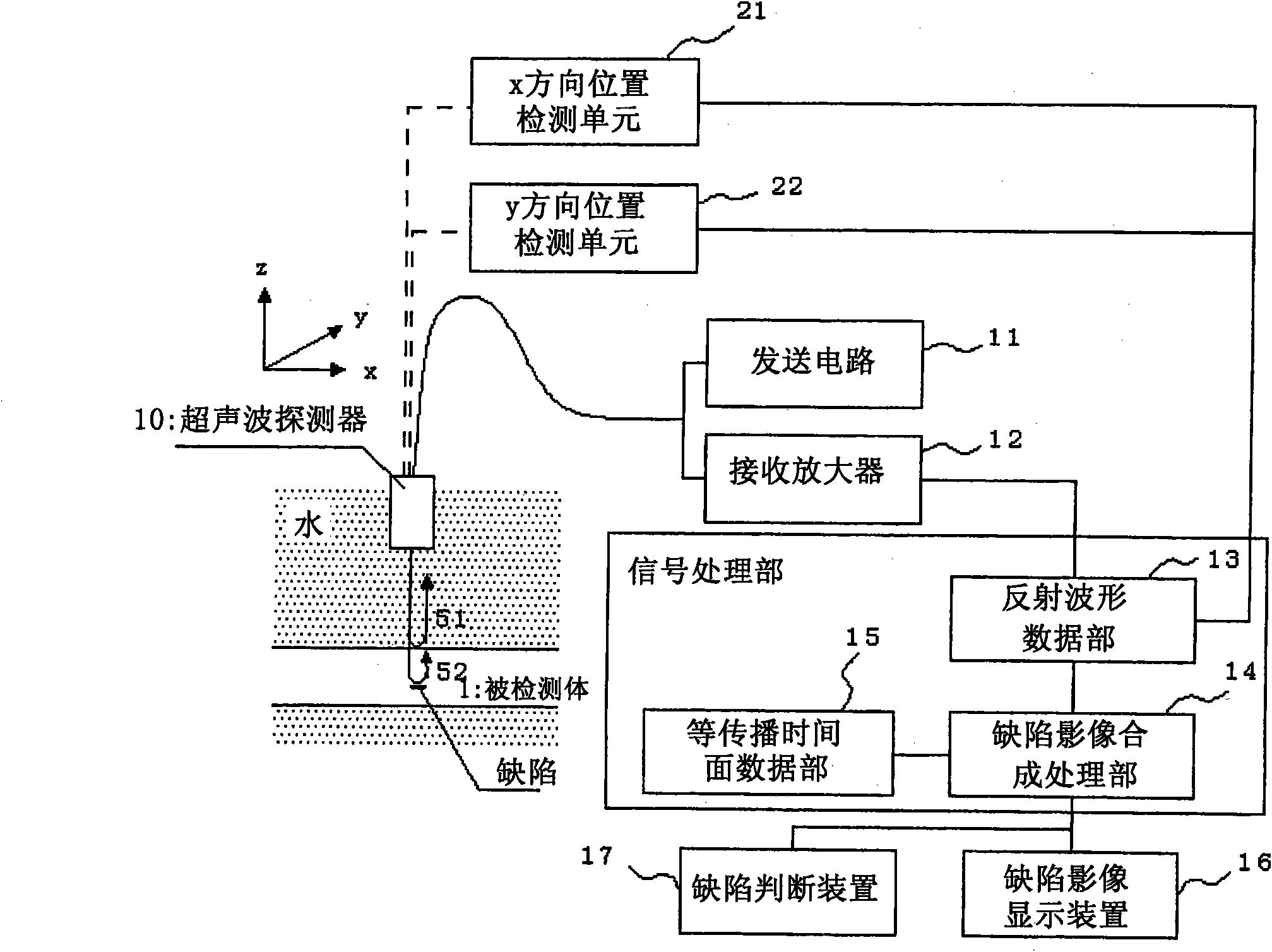

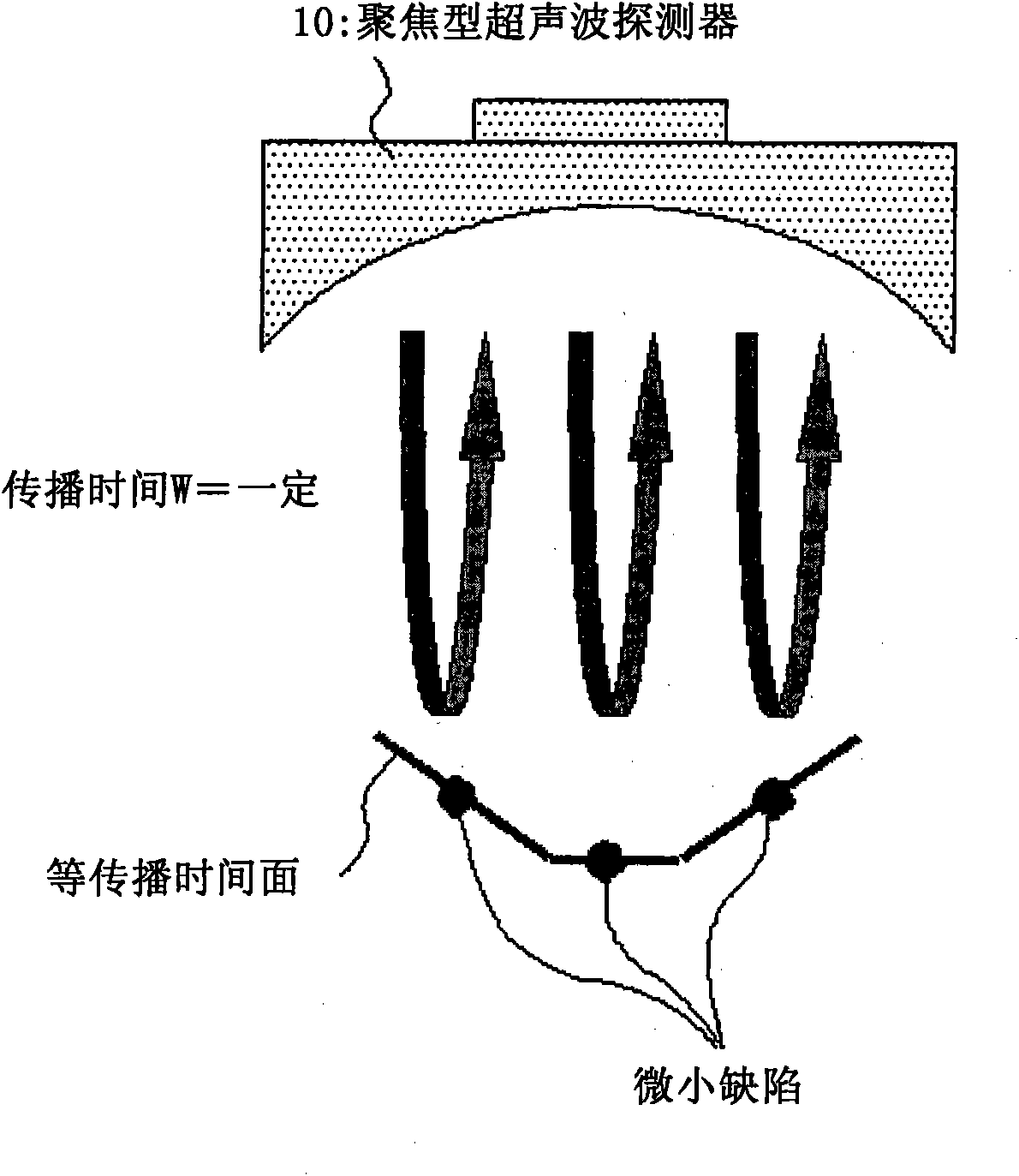

[0099] figure 1 It is a block diagram showing the configuration of an ultrasonic imaging device as an example of the ultrasonic measurement device according to Embodiment 1 of the present invention.

[0100] figure 1 Among them, 1 represents the object to be inspected. In this example, the object 1 is a stationary object, water is used as a medium, and internal defects are imaged using a liquid immersion method. 10 is a focused ultrasonic probe for transmitting and receiving focused beams (hereinafter referred to simply as "ultrasonic probe"), which transmits focused ultrasonic beams towards the subject 1 through electric pulses of a certain period from the transmitting circuit 11, and receives signals from the subject 1. Reflected waves (echoes) from the surface and interior of the body 1. The received signal is amplified by the receiving amplifier 12 to an appropriate level suitable for subsequent signal processing.

[0101]In addition, the transmitting circuit 11 and ...

Embodiment approach 2

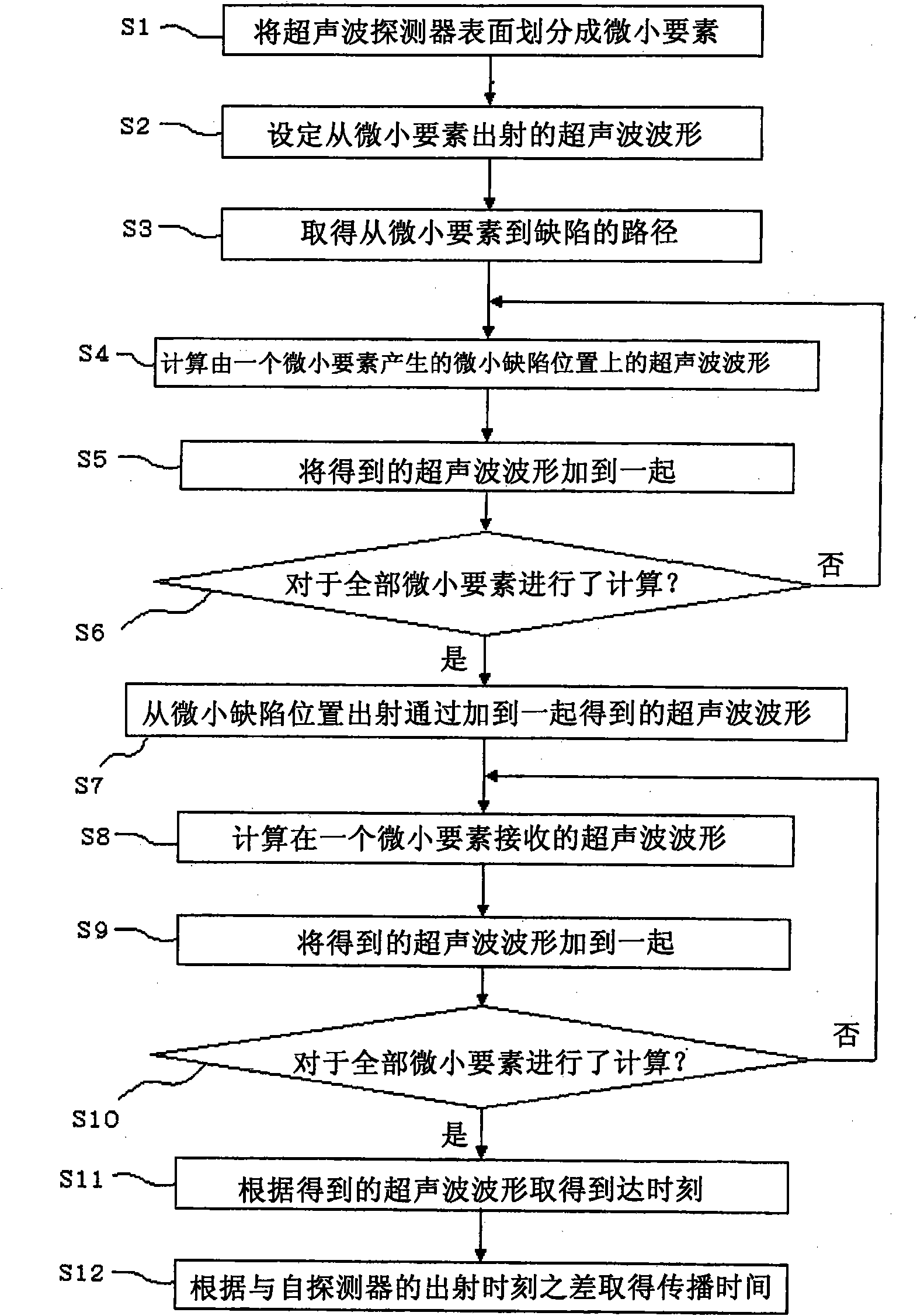

[0150] This embodiment 2 is to make figure 1 An example in which the defective image synthesis processing unit 14 performs processing different from the above-mentioned arithmetic processing. The defect image synthesis processing unit 14 of the second embodiment uses delay time data instead of the above-mentioned equal propagation time plane data. Therefore, instead of the isopropagation time plane data unit 15, a storage device (not shown) for storing delay time data is provided. The delay time data (delay time group) is based on the variation data of the propagation time (performing Image 6 The data before the transformation) to find out, such as Figure 13 As shown in the conceptual diagram of , the longer the variation data of the propagation time, the smaller the delay time, and the shorter the variation data, the larger the delay time. Similar to the isopropagation time surface data, each value corresponding to the water distance / defect depth is calculated and store...

Embodiment approach 3

[0161] Figure 14 It is a block diagram showing the configuration of an ultrasonic imaging device, which is an example of the ultrasonic measurement device according to Embodiment 3 of the present invention. Figure 14 Among them, 1 represents the object to be inspected. In this example, the object to be inspected 1 is a static object to be inspected, water is used as a medium, and internal defects are imaged using a liquid immersion method. 10 is an array-type ultrasonic probe for transmitting and receiving ultrasonic waves. The electric pulses of a certain period from the transmitting circuit 111 are sent to each vibrator through the drive element selection circuit 112 to send ultrasonic beams toward the subject 1, and receive signals from the subject 1. Reflected waves (echoes) from the surface and interior of the body 1. The received signal is subjected to aperture synthesis processing by the receiving circuit 113 and the array signal processing circuit 114, and amplifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com