Capsule pill feeding mechanism

A technology for capsules, tablets and pills, which is applied in the field of capsule feeding mechanisms, can solve the problems of limiting the range of feeding types and affecting the wide application of capsules, and achieves high yield, high work efficiency, and improved wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

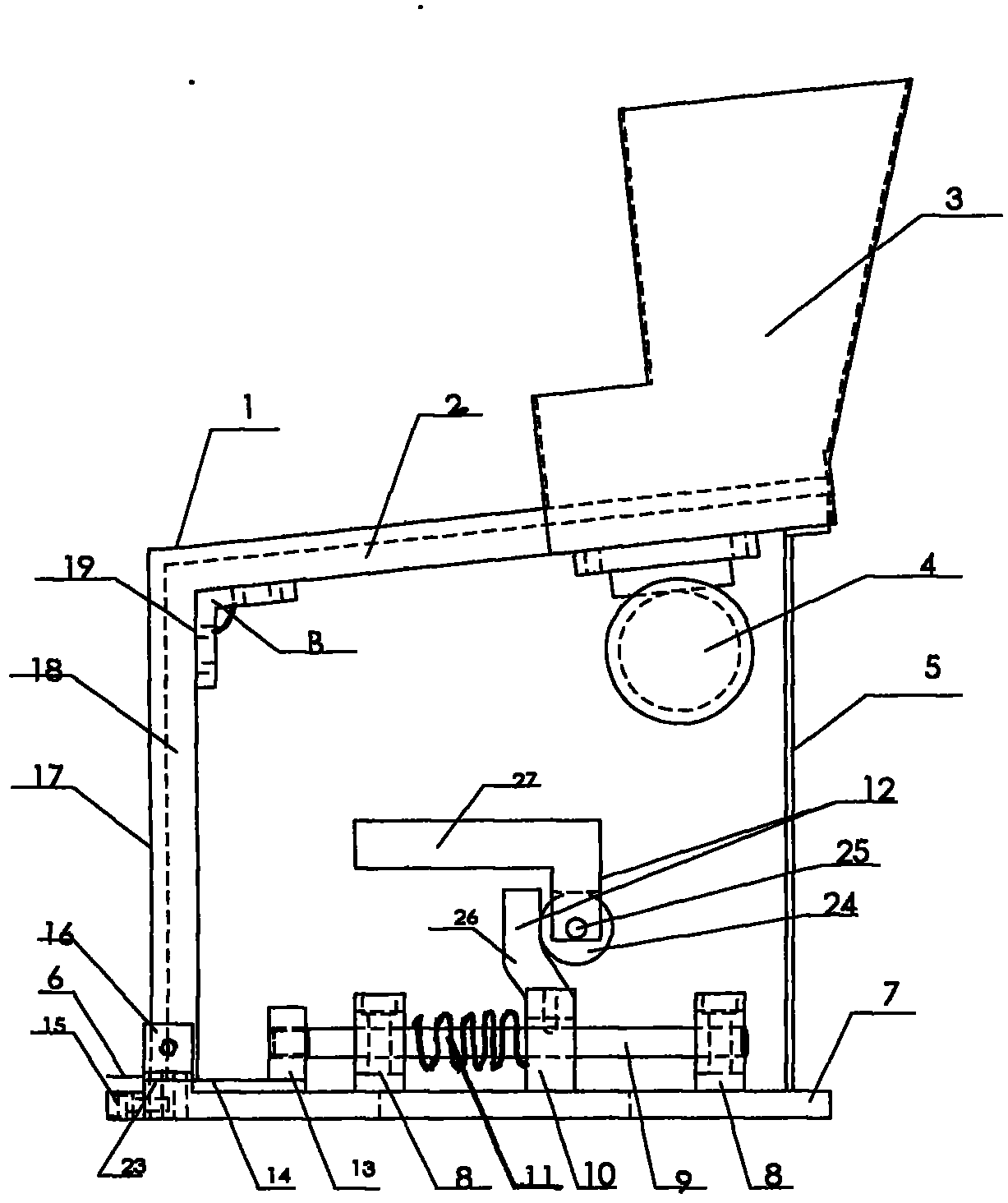

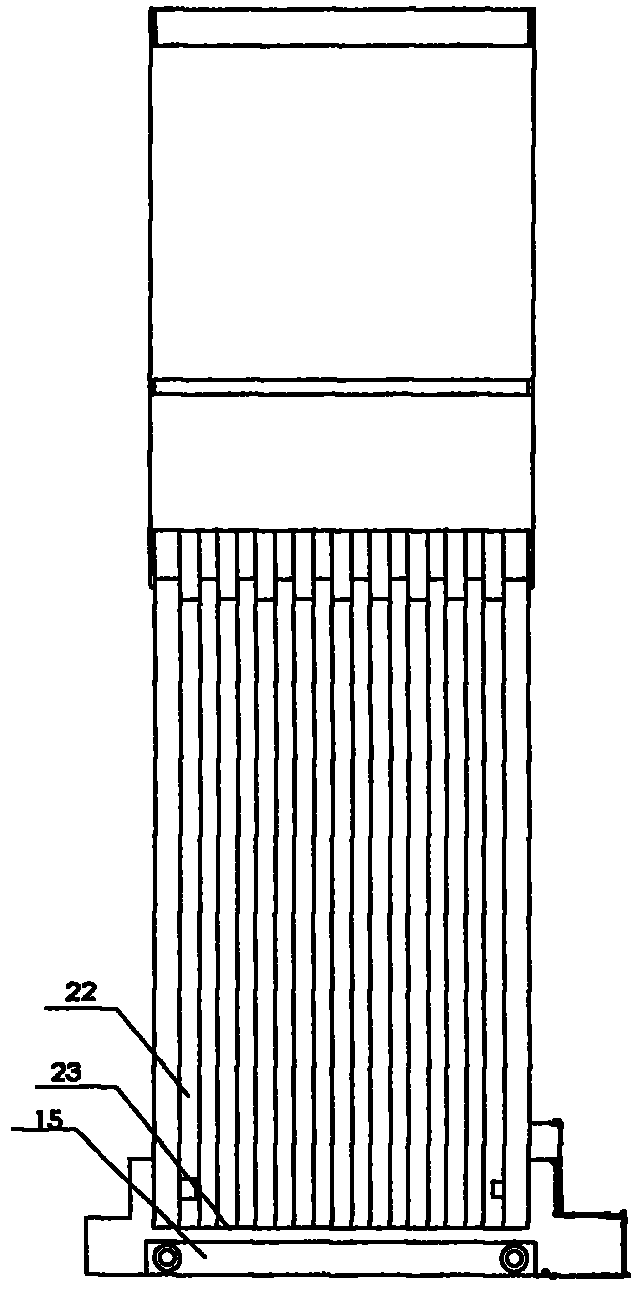

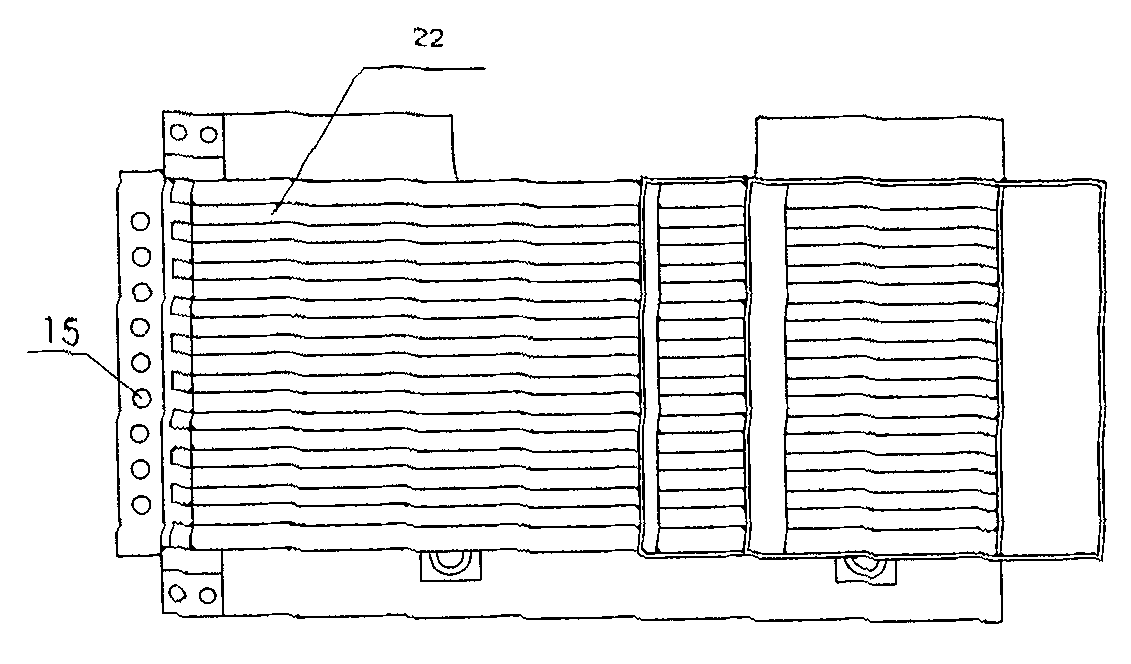

[0010] refer to Figure 1 to Figure 3 , the capsule tablet pill feeding mechanism of the present invention comprises a base plate 7 and a hopper 3, bearing blocks 8 (for two pieces) are mounted on the base plate 7, and support shafts 9 are installed between the support shafts, on the support shafts 9, slide The block 10 is connected to the slider pushing assembly 12, and is connected to the push plate 14 provided on the bottom plate 7 through the shaft support seat 13 at the end of the support shaft 9; on the bottom plate 7 and on the side of the push plate 14 The feed plate 20 (it comprises the feed plate 2 that is horizontally arranged and the storage plate 18 that is vertically arranged that its inner included angle is arranged at an obtuse angle by support frame 16 is equipped with, and the inner included angle B between these two plates is Obtuse angle, its inner angle place is equipped with support angle plate 19), and described hopper 3 is contained on the feeding plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com