Silicon steel sheet punching process and device for simultaneously punching two holes

A silicon steel sheet and punching technology, which is applied in the field of transformers, can solve the problems of slow processing speed, affecting the stacking speed of the iron core and the flatness of the end face, and it is not easy to ensure the accuracy, so as to achieve the effect of improving the punching quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0012] A silicon steel sheet punching process for punching two holes at the same time, including the following process steps: ① Install a guide shaft and a guide sleeve between the stroke slider on the upper side of the punching machine and the bottom worktable to improve the precision of the punching machine; Put on the processing slideway, install the double punches on the slideway, and adjust the distance between the double punches freely within a certain distance to meet the distance between the two holes on the iron yoke; ③ Install the lower punch on the slide of the bottom worktable On the road, and align it with the upper punch during the debugging process, two holes can be punched at the same time.

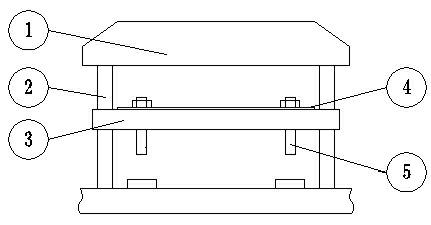

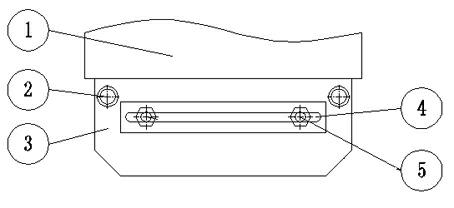

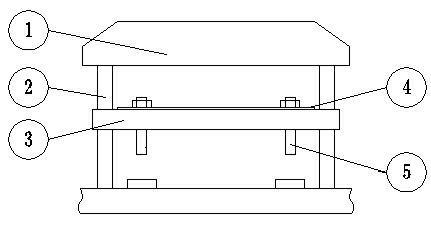

[0013] A silicon steel sheet punching equipment for punching two holes at the same time, including a punch 1, a guide shaft 2, a guide slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com