Assembling, adjusting and fixing component for laser cutter

A laser cutting machine, installation and adjustment technology, used in large fixed members, laser welding equipment, metal processing machinery parts, etc., can solve the problems of high procurement cost, time-consuming and laborious, and achieve firm and reliable installation, easy adjustment and operation, and simple structure. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

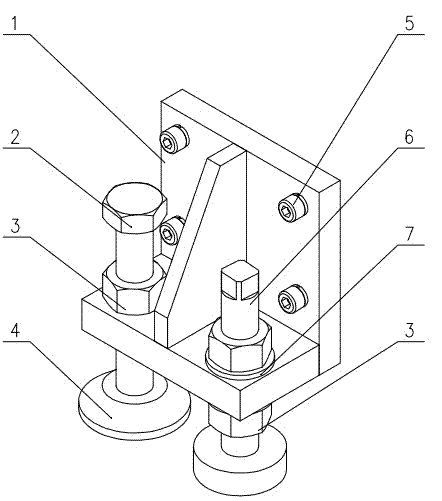

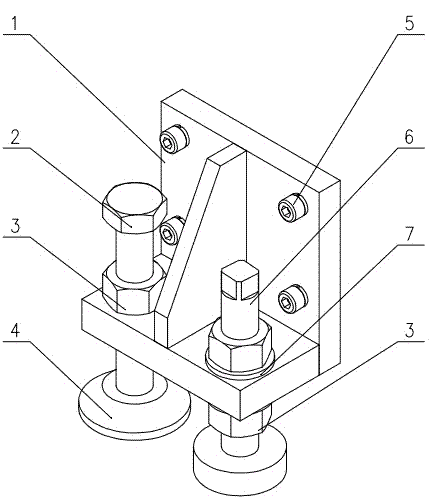

[0011] Such as figure 1 As shown, the installation, adjustment and fixation assembly of the laser cutting machine of the present invention includes the installation, adjustment and fixation assembly including the installation frame 1, the adjustment bolt rod 2, the hex nut 3, the foot pad 4, the screw 5, the adjustment bolt pad 6, and the flat washer 7. Fix the mounting frame 1 on the machine bed with screws 5, install the hex nut 3 above the adjusting bolt rod 2, screw the adjusting bolt rod 2 into the threaded hole of the mounting frame 1, and place the foot pad 4 under the adjusting bolt rod 2 , The adjusting bolt pad 6 is installed in another hole of the mounting frame 1, and the hex nut 3 and the flat washer 7 are installed on the adjusting bolt pad 6 respectively.

[0012] The working principle of the present invention is as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com