Feeding machine and multi-station feeding method for multi-station reinforcing steel bar wire rod

A multi-station, feeding machine technology, applied in the field of feeding machines, can solve the problems of low efficiency of disk feeding, difficult to balance force, large floor space, etc., to achieve reasonable force, small floor space, The effect of saving labor and time and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below through specific examples.

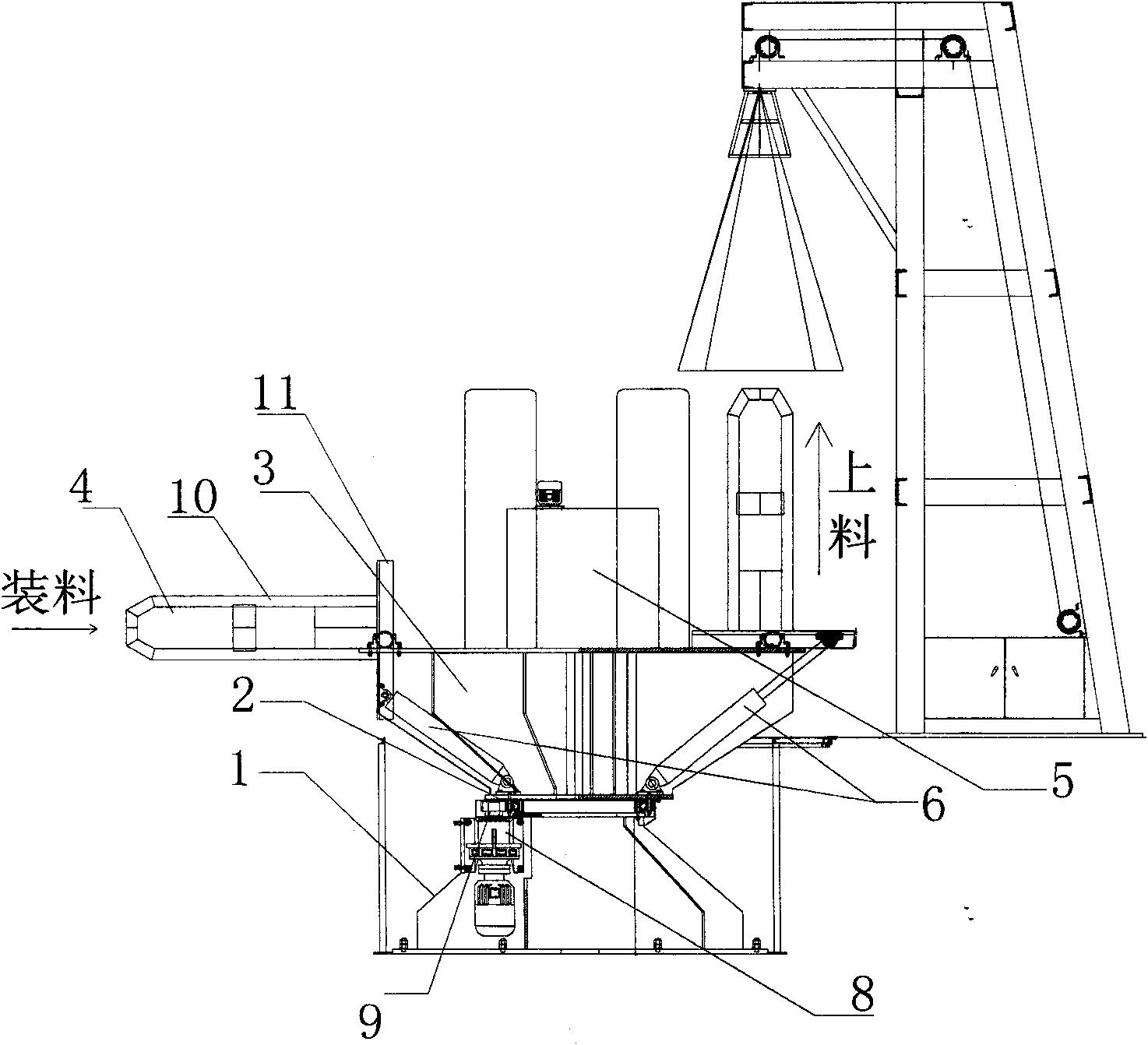

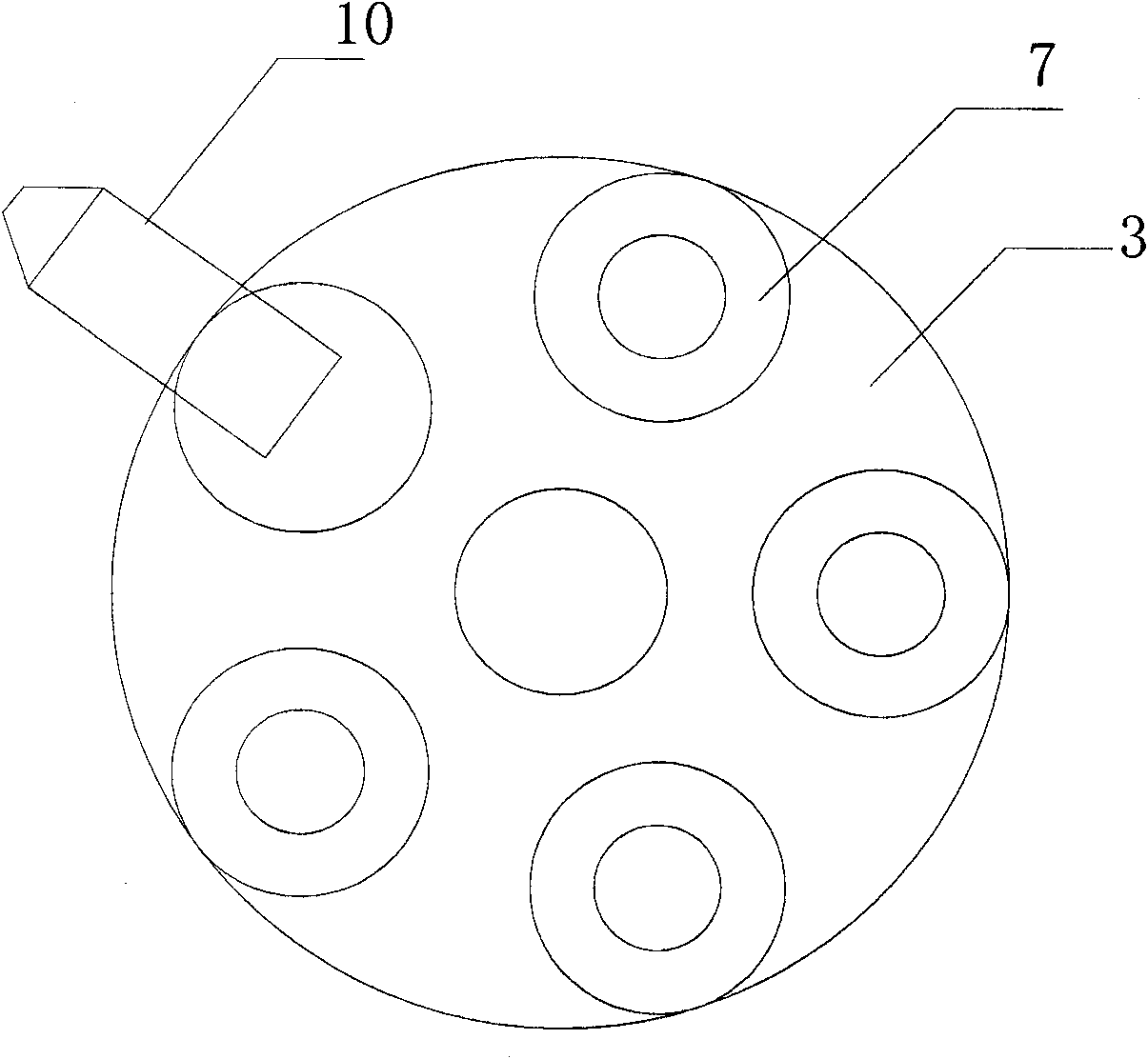

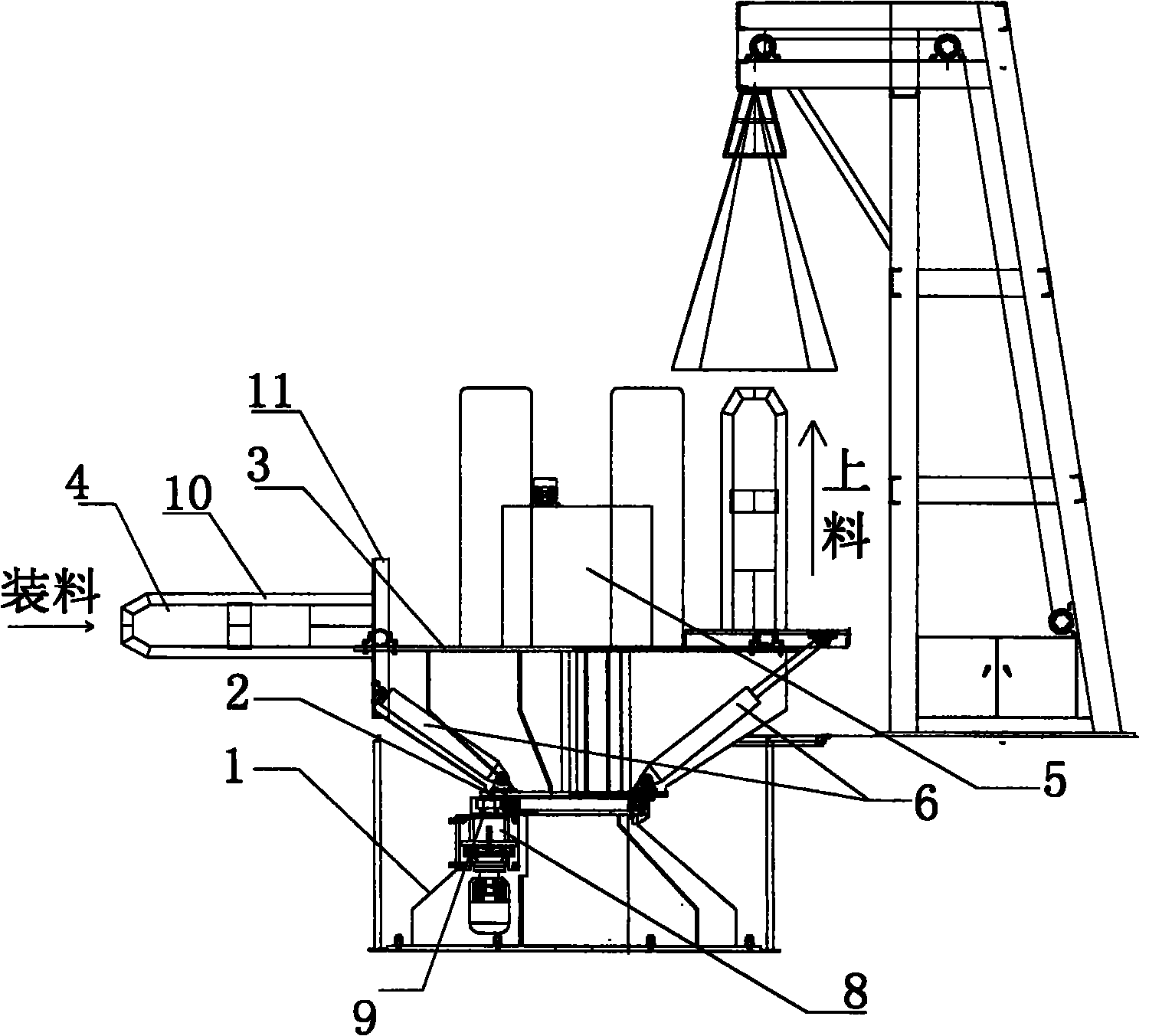

[0023] As attached in the manual figure 1 As shown, the present invention is a kind of multi-station steel bar round feeder, including a turntable 3, the turntable 3 is installed on the feeder base 1 through the turntable bearing 2 to rotate relative to the feeder base 1, and the bottom of the turntable 3 is set There are gears, and the gears are engaged with the driving gear 9 installed on the output shaft of the reducer motor 8 on the feeder base 1, and the reducer motor 8 drives the turntable 1 to rotate. There are five stations 7 arranged on the turntable 3, see the accompanying drawings figure 2 , It can be loaded at one station and another at the same time, realizing continuous operation. Each station 7 is hinged with an overturning frame 4 for placing a disc circle. The overturning frame 4 includes a bottom bracket 11 hinged on the edge of the turntable 1 and a pillar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com