Hermetic container and manufacturing method of the same

An airtight container and manufacturing method technology, applied in exhaust sealing, manufacturing tools, cold cathode manufacturing, etc., can solve problems such as poor bonding, poor sealing material level, cracks, etc., and achieve the effect of improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

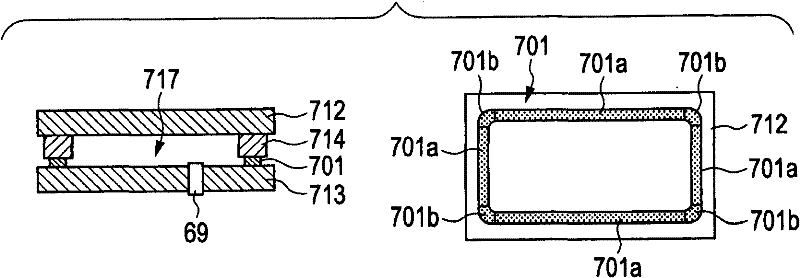

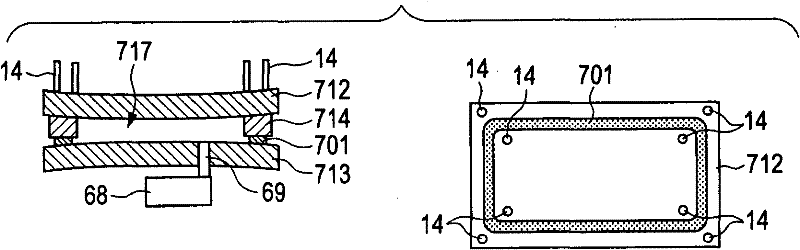

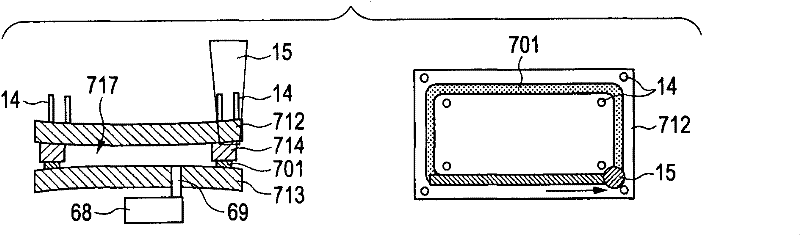

[0021] Embodiments of the present invention will be described below with reference to the accompanying drawings. Although a container used as an airtight container in an image display device such as FED, OLED, PDP, etc. will be described below, the airtight container of the present invention is not limited to them and can be applied to all containers that are airtightly sealed . As an example of such an airtight container, there is a vacuum insulated glass container.

[0022] In particular, the manufacturing method of an airtight container according to the present invention can be suitably applied to the manufacturing method of a container having a pressure-reduced inner space. In an image display device such as an FED having a depressurized internal space, a joint strength that can cope with the atmospheric pressure caused by the negative pressure of the internal space is required. However, according to the method of manufacturing an airtight container in the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of thermal expansion | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com