Method for Improving Lamination Performance of Calendered Black Rubber Strip Film for Rubber Shoes

A black rubber, calendering type technology is applied in the field of improving the lamination performance of calendered black rubber strip film for rubber shoes. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

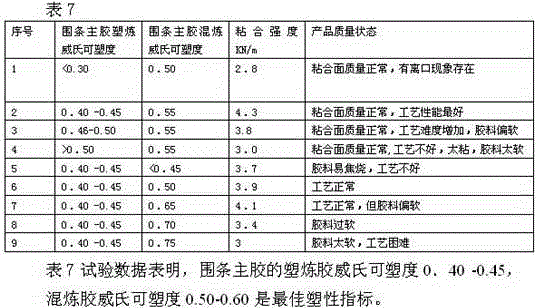

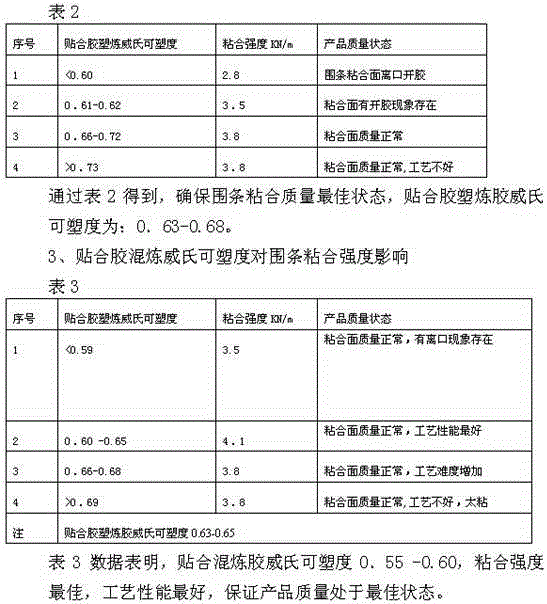

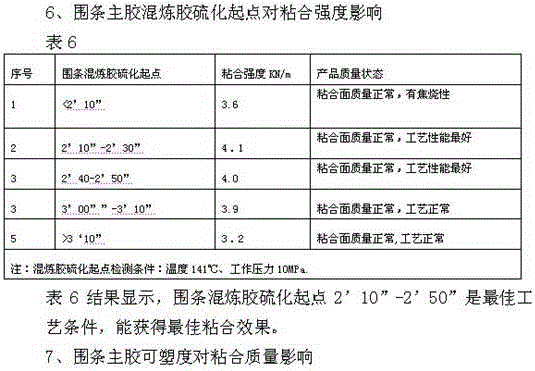

Examples

Embodiment 1

[0017] Embodiment 1 of the present invention: a method for improving the lamination performance of calendered black rubber strip film for rubber shoes. In the preparation process of the main rubber, the Vickers plasticity of the masticated rubber used to prepare the main rubber is 0.40, which is used for the preparation of the main rubber. The Vickers plasticity of the mixed rubber of the main rubber is 0.50, and the vulcanization starting point of the main rubber mixed rubber is 2 minutes and 30 seconds; degree is 0.68, the Vickers plasticity of the prepared adhesive compound is 0.62, and the vulcanization starting point of the compound is 2 minutes and 40 seconds; the black adhesive formula uses 15 parts of composite resin DS-B; the prepared The laminating glue is calendered by the upper roller and the middle roller of the calender, and then the main glue and the calendered laminating glue are calendered and bonded by the middle roller and the lower roller of the calender to ...

Embodiment 2

[0018] Embodiment 2 of the present invention: a method for improving the lamination performance of calendered black rubber strip film for rubber shoes. In the preparation process of the main rubber, the Vickers plasticity of the plasticized rubber used to prepare the main rubber is 0.45. The prepared main rubber The Vickers plasticity of the rubber compound is 0.60, and the vulcanization starting point of the compound is 2 minutes and 10 seconds; during the preparation process of the laminating rubber, the Vickers plasticity of the plastic compound used to prepare the laminating rubber is 0.66 The Vickers plasticity of the mixed rubber of the prepared adhesive is 0.65, and the vulcanization starting point of the mixed rubber is 2 minutes and 40 seconds; the black adhesive formula uses 15 parts of composite resin DS-B; the prepared adhesive Calendering is carried out by the upper and middle rollers of the calender, and then the main rubber and the calendered laminating glue are ...

Embodiment 3

[0019] Embodiment 3 of the present invention: a method for improving the lamination performance of calendered black rubber strip film for rubber shoes. During the preparation of the main rubber, the Vickers plasticity of the masticated rubber used to prepare the main rubber is 0.42, which is used for the preparation of the main rubber. The Vickers plasticity of the mixed rubber of the main rubber is 0.50, and the vulcanization starting point of the mixed rubber is 2 minutes and 50 seconds; during the preparation process of the laminating rubber, the Vickers plasticity of the plasticized rubber used to prepare the laminating rubber is 0.72, the Vickers plasticity of the mixed rubber of the prepared adhesive is 0.60, and the vulcanization starting point of the mixed rubber is 3 minutes and 10 seconds; the black adhesive formula uses 15 parts of composite resin DS-B; the prepared adhesive The glue is calendered by the upper roller and the middle roller of the calender, and then th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com