Edge self-sealing type transparent PVC film and preparation method thereof

A transparent and edge technology, applied in the direction of film/sheet adhesives, adhesives, etc., can solve the problems of decorative film falling off, easy edge lifting, pulling deformation or scratching, etc., to avoid energy waste and reinforcement Stable, sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

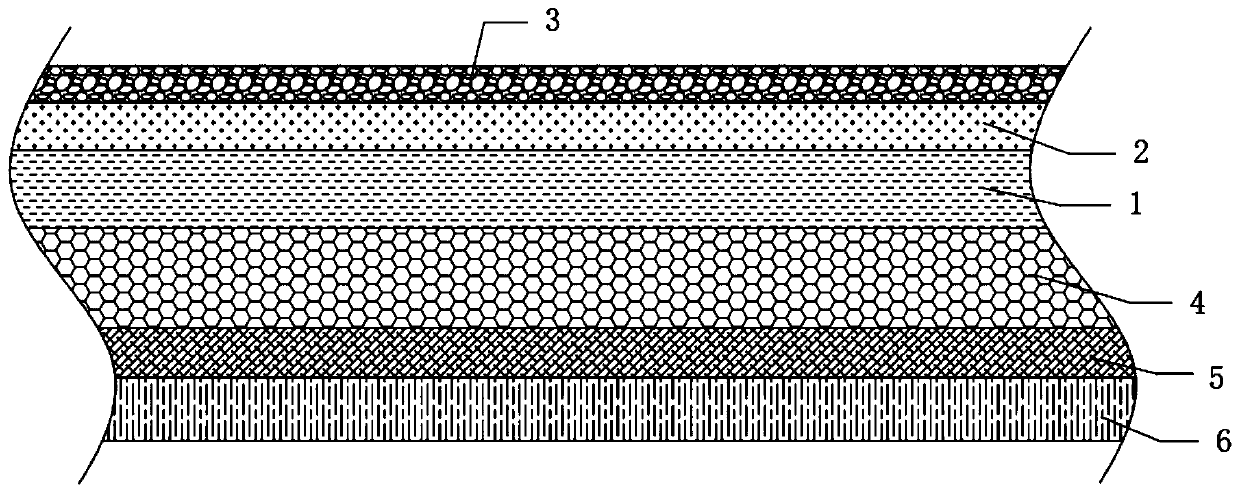

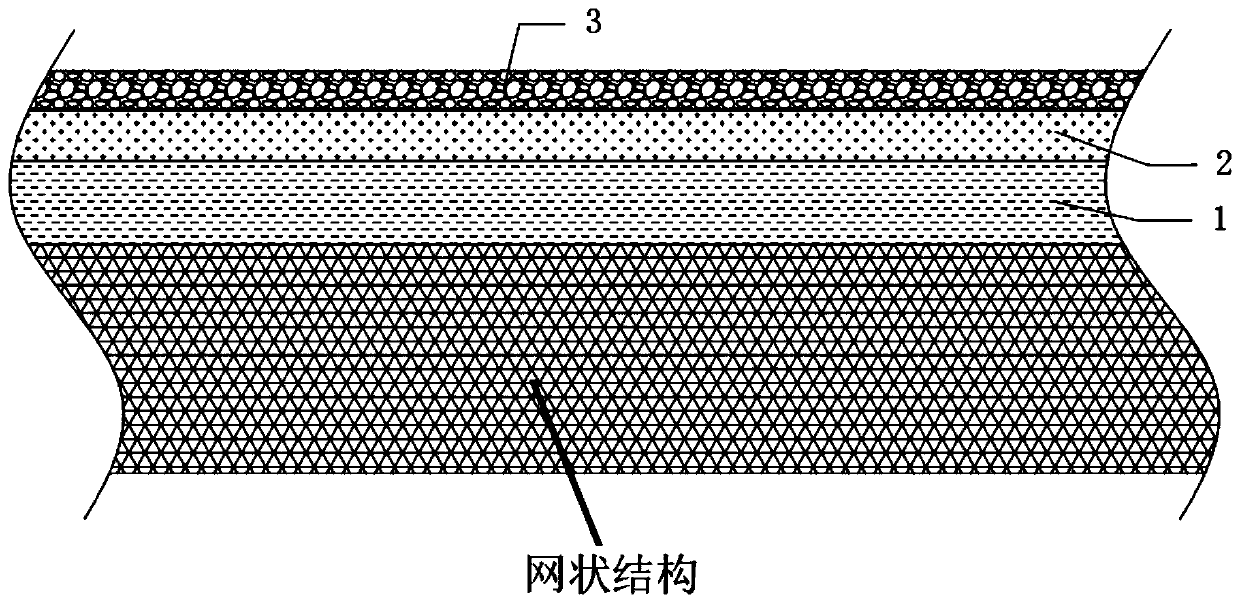

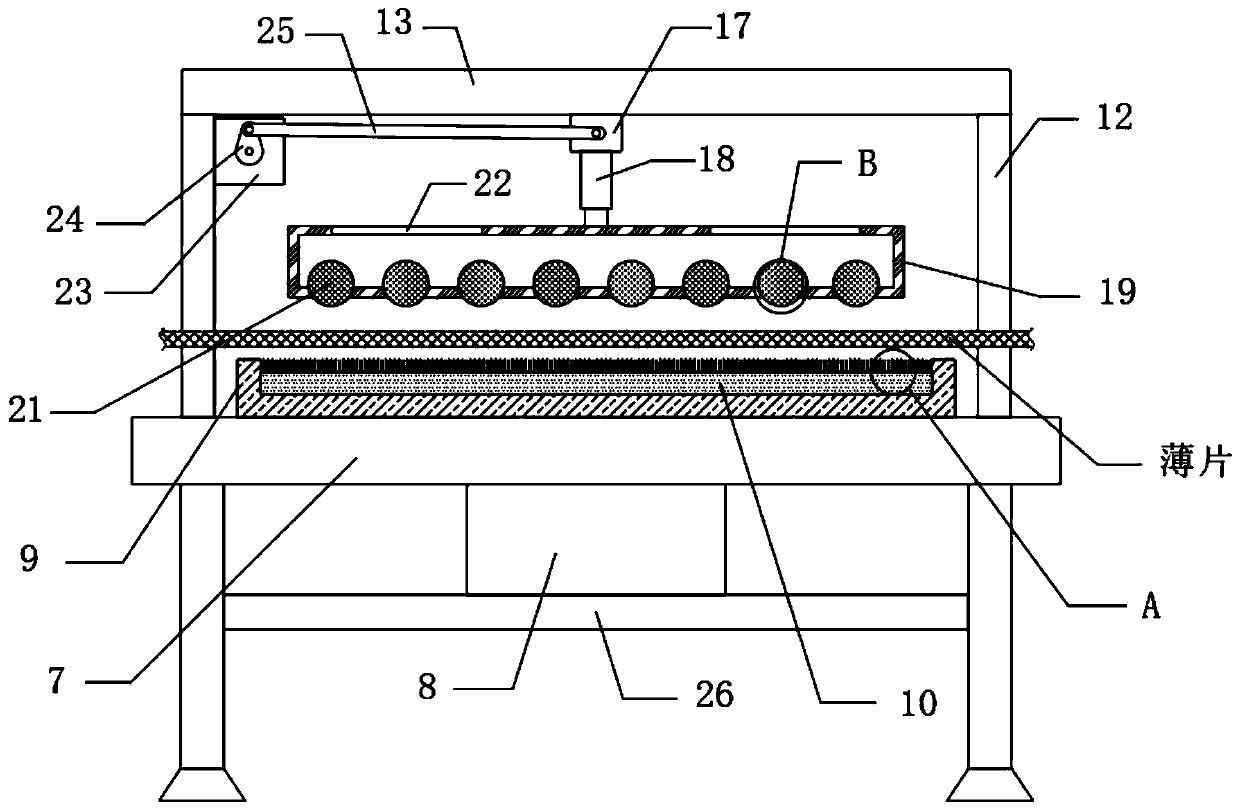

[0046] see Figure 1-7 , a kind of edge self-sealing type transparent PVC film and preparation method thereof, comprise PVC substrate 1, please refer to Figure 1-2 , the upper surface of the PVC substrate 1 has an anti-ultraviolet layer 2, and the upper surface of the anti-ultraviolet layer 2 is bonded with a friction-resistant layer 3, and the friction-resistant layer 3 is made of asbestos fiber material, and asbestos fiber is a very good friction-resistant material , the lower surface of the PVC substrate 1 is bonded with reticular fiber 4, elastic fiber 5 and glue 6, the glue 6 is made of waterproof glue material, the waterproof glue has strong viscosity, and its viscosity will not be affected by water vapor, and the mesh shape Fiber 4, elastic fiber 5 and glue 6 are interwoven into a network structure;

[0047] Include the following steps:

[0048] S1, first press the anti-ultraviolet layer 2 and the anti-friction layer 3 and the PVC substrate 1 in sequence, and then pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com