Production method for VN reinforcement bar with yield strength not less than 400MPa

A technology of yield strength and production method is applied in the production field of VN steel bars with a yield strength of 400MPa, which can solve the problems of the surface quality of steel bars cannot meet the requirements and the yield of VN is low, so as to improve the surface quality of products, reduce production costs, Good mechanical properties and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

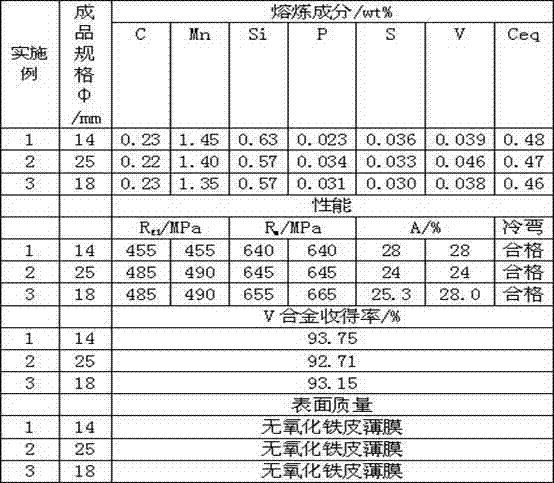

Embodiment 1

[0023] The production yield strength is HRB400 grade, the steel bar diameter is 14 mm, and its melting chemical composition and weight percentage are: C: 0.23%, Mn: 1.45%, Si: 0.63%, P: 0.023%, S: 0.036%, V: 0.039 %, Ceq: 0.48; the test conditions are in a 70t converter, and the steps are:

[0024] 1) Fill 89% of the total volume of molten iron in a 70-ton converter, that is, the amount of molten iron loaded is 62.3 tons, and the weight percentage P of phosphorus in the molten iron is controlled at 0.110%, and the weight percentage S of sulfur is 0.047%;

[0025] 2) Add 11% of the total volume of steel scrap to the 70-ton converter, that is, 7.7 tons;

[0026] 3) Conventional oxygen blowing;

[0027] 4) Conventional baking of the ladle;

[0028] 5) Put the added VN16 alloy into a container made of ordinary quality carbon structural steel and seal it and put it into a 70-ton steel ladle. The amount of addition: the diameter of the steel bar is 14 mm, and the amount of additi...

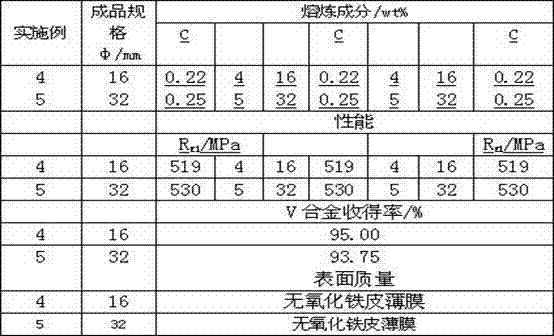

Embodiment 2

[0038] The production yield strength is HRB400 grade, the steel bar diameter is 25 mm, and its melting chemical composition and weight percentage are:

[0039] C: 0.22%, Mn: 1.40%, Si: 0.57%, P: 0.034%, S: 0.033%, V: 0.046%, Ceq: 0.47; the test conditions are in a 35t converter, and the steps are:

[0040] 1) Fill 87% of the total volume of molten iron in a 35-ton converter, that is, the amount of molten iron loaded is 30.45 tons, and the weight percentage P of phosphorus in the molten iron is controlled at 0.120%, and the weight percentage S of sulfur is 0.049%;

[0041] 2) Add 13% of the total volume of steel scrap to the 35-ton converter, that is, 4.55 tons;

[0042] 3) Conventional oxygen blowing;

[0043] 4) Conventional baking of the ladle;

[0044] 5) Put the added VN16 alloy into a container made of ordinary quality carbon structural steel and seal it and put it into a 35-ton steel ladle. The amount of addition: the diameter of the steel bar is 25 mm, and the amount...

Embodiment 3

[0054] The production yield strength is HRB400 grade, the steel bar diameter is 18 mm, and its melting chemical composition and weight percentage are:

[0055] C: 0.23%, Mn: 1.35%, Si: 0.57%, P: 0.031%, S: 0.030%, V: 0.038%, Ceq: 0.46; the test conditions are in a 35t converter, and the steps are:

[0056] 1) Fill the 35-ton converter with 85.2% of the total volume of molten iron, that is, the amount of molten iron loaded is 29.82 tons, and the weight percentage P of phosphorus in the molten iron is controlled at 0.115%, and the weight percentage S of sulfur is 0.048%;

[0057] 2) Add 14.8% of the total volume of steel scrap to the 35-ton converter, that is, 5.18 tons;

[0058] 3) Conventional oxygen blowing;

[0059] 4) Conventional baking of the ladle;

[0060] 5) Put the added VN16 alloy into a container made of ordinary quality carbon structural steel and seal it and put it into a 35-ton steel ladle. The amount of addition: the diameter of the steel bar is 18 mm, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com