Aluminum-titanium foil

An aluminum-titanium, weight percent technology, applied in the field of aluminum-titanium foil, can solve problems such as threats to health, bacterial invasion of food or medicine, deterioration of food and medicine, etc., and achieves the effect of improving bacteriostatic performance and increasing the stability of mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

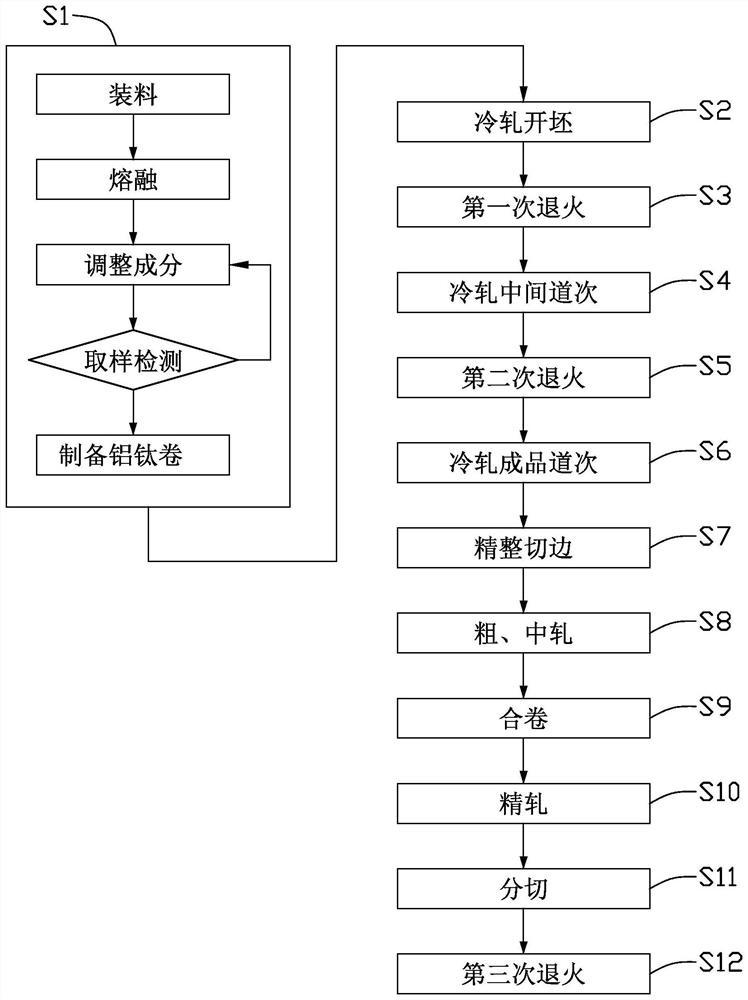

[0027] see figure 1 , the embodiment of the present application provides a kind of preparation method of aluminum-titanium foil comprising:

[0028] S1. Casting and rolling composition adjustment

[0029] Charging: loading solid materials into the melting furnace, including aluminum ingots and scrap aluminum;

[0030] Melting: After heating up to 710-750°C, the solid material melts into a high-temperature molten liquid;

[0031] Adjustment of composition: According to the calculation of the composition of aluminum-titanium foil, add aluminum-silicon alloy, iron agent, aluminum-titanium alloy, and copper agent, and adjust the composition of the high-temperature melt by adding aluminum-silicon alloy, iron agent, aluminum-titanium alloy, and copper agent; the composition of aluminum-titanium foil The range is by weight percentage: Fe: 0.7-1.1%, Si: 0.2-0.3%, Cu: 0.01-0.03%, Ti: 0.05-0.10%, and the balance is Al and impurities;

[0032] Sampling and detection: after stirring an...

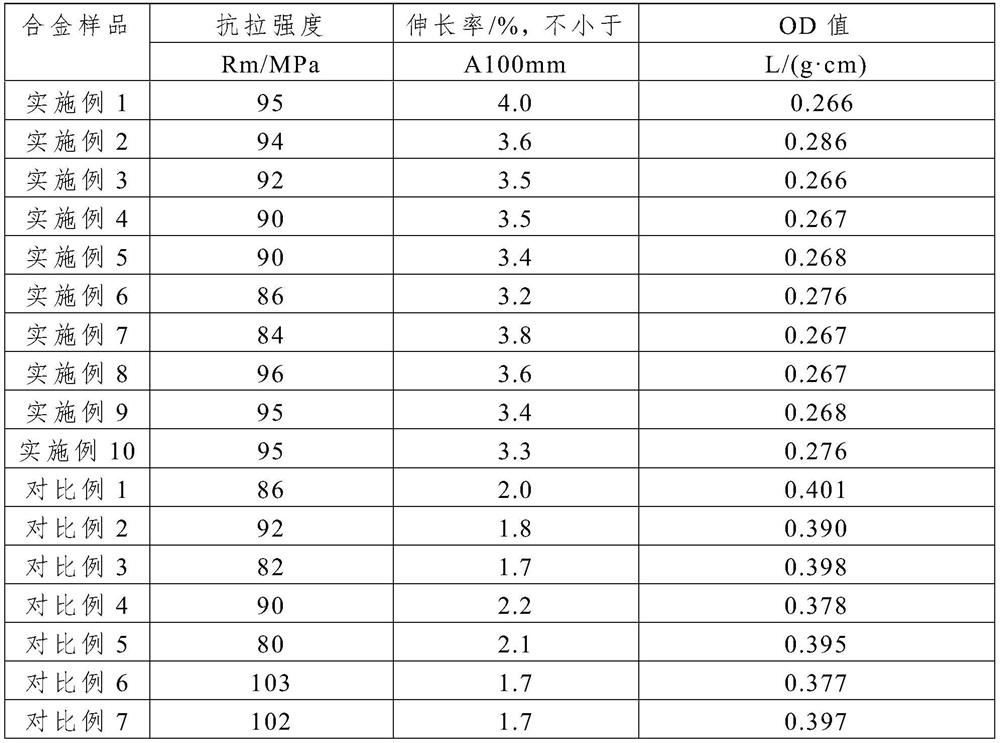

Embodiment 1

[0052] Embodiment 1: Prepare aluminum-titanium foil according to the following steps:

[0053] Determine the composition of the aluminum-titanium foil by weight percentage: Fe: 1.1%, Si: 0.3%, Cu: 0.03%, Ti: 0.10%, and the balance is Al and impurities.

[0054] After the solid material is loaded into the melting furnace and the temperature is raised to about 720°C, the solid material is melted into a high-temperature molten liquid.

[0055] According to the composition of solid material and aluminum-titanium foil, add aluminum-silicon alloy, iron agent, aluminum-titanium alloy, and copper agent to the high-temperature molten liquid, and adjust the composition of the high-temperature molten liquid by adding aluminum-silicon alloy, iron agent, aluminum-titanium alloy, and copper agent. .

[0056] Pour the aluminum-titanium liquid (that is, the high-temperature molten solution) that meets the composition standards in the smelting furnace into the holding furnace, and confirm tha...

Embodiment 2

[0068] Embodiment 2: Prepare aluminum-titanium foil according to the following steps:

[0069] It is determined that the composition of the aluminum-titanium foil is: Fe / Si≥3 by weight percentage. Specifically, its chemical composition by weight percentage is: Fe: 1.1%, Si: 0.2, Cu: 0.01, Ti: 0.05, and the balance is Al and impurities.

[0070] After the solid material is loaded into the melting furnace and the temperature is raised to about 720°C, the solid material is melted into a high-temperature molten liquid.

[0071] According to the composition of solid material and aluminum-titanium foil, add aluminum-silicon alloy, iron agent, aluminum-titanium alloy, and copper agent to the high-temperature molten liquid, and adjust the composition of the high-temperature molten liquid by adding aluminum-silicon alloy, iron agent, aluminum-titanium alloy, and copper agent. .

[0072] Pour the aluminum-titanium liquid (that is, the high-temperature molten solution) that meets the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com