Charge coupled device (CCD) detection device for automatic burling machine

A detection device and cloth inspection machine technology, applied in the direction of optical testing defects/defects, etc., can solve the problems of inability to effectively distinguish defects, low detection rate, etc., and achieve easy analysis and identification of defects, clear cloth line stripes, and improved detection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

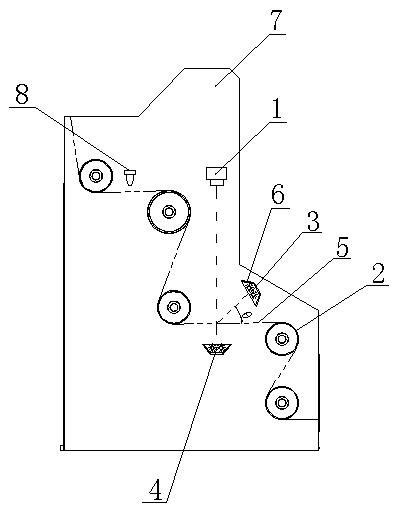

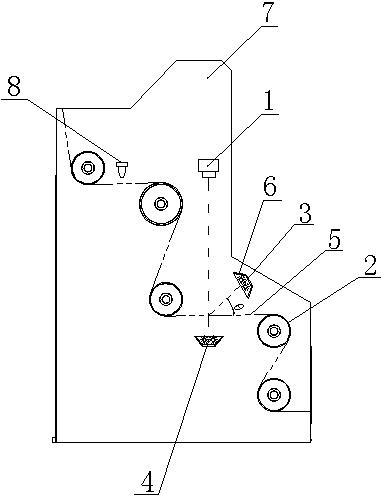

[0013] As shown in the figure, a CCD detection device of an automatic cloth inspection machine includes a CCD camera 1, a cloth guide roller 2 and a light source. The CCD camera 1 , the cloth guide roller 2 and the light source are arranged in the casing 7 . The cloth 5 is arranged between two cloth guide rollers 2, the light source includes a main light source 3 and a backlight 4, the backlight 4 is arranged on one side of the cloth 5, the CCD camera 1 is arranged on the other side of the cloth 5, the CCD camera 1 and the backlight The source 4 is arranged oppositely, the intersection of the main optical axis of the cloth 5 and the CCD camera 1 is the detection area, and the main light source 3 is arranged between the cloth 5 and the CCD camera 1 . In order to reduce the impact of ambient light on the shooting clarity, the preferred method is: the cloth 5 is horizontally arranged between two cloth guide rollers 2, and the cloth 5 is flattened by the cloth guide rollers 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com