Automatic detection equipment of laser paper and laser membranes

An automatic detection and laser film technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of unable to meet production development, missed detection, easy fatigue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

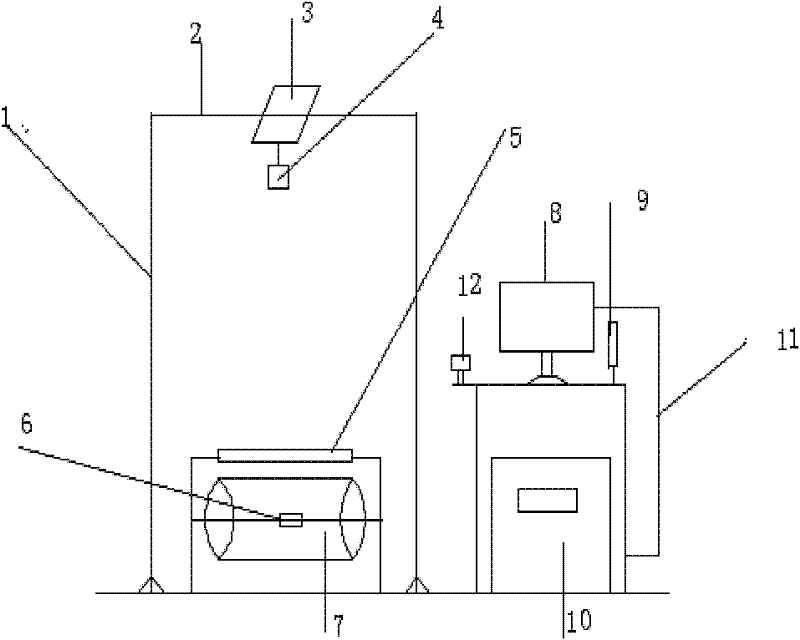

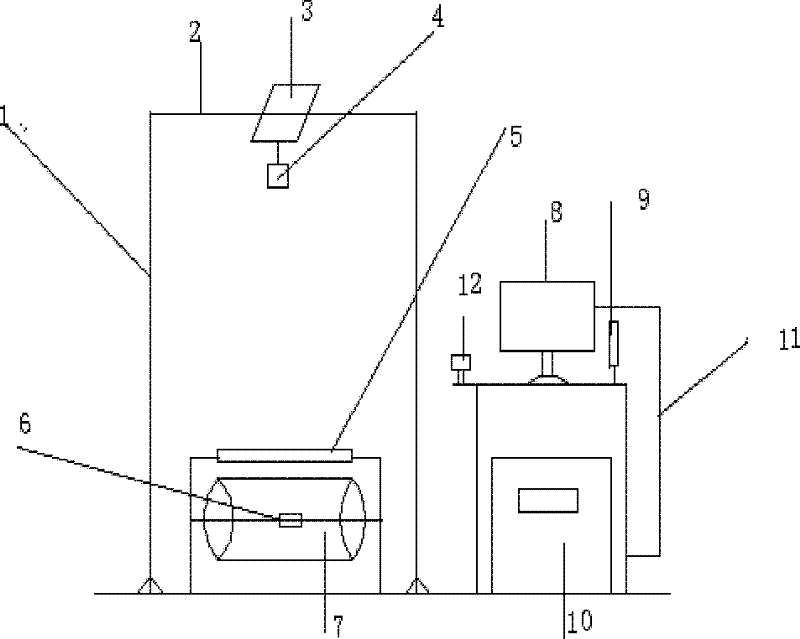

[0012] figure 1 It is the automatic detection equipment of laser paper and laser film involved in the present invention. The automatic detection equipment is installed on the output terminal after the process of film pressing, coating, coating, etc., and the output terminal is the rotating roller 7. Parts (ie laser paper and laser film) are on roller 7. An illuminating lamp 5 and an imaging device are arranged above the roller 7. As shown in the figure, the illuminating lamp 5 is arranged on a support and is in working condition all the time. Preferably, a backlight light source can be used, that is, the illuminating lamp 5 is arranged between two rollers 7 arranged side by side. The imaging device is a camera 4, which is fixed on a vertical support 1. By adjusting the angle and height of the camera 4, high-definition images can be obtained. In this embodiment, the camera 4 is fixed on the camera bracket 3 , and the camera bracket 3 is fixed on the upper cross bar 2 of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com