Apparatus for automatically inspecting defects of PCB (printed circuit board)

A PCB circuit board, automatic inspection technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of high mechanical movement precision, high maintenance technical requirements, low manufacturing cost, etc., and achieve a high degree of automation , high detection accuracy and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing of description:

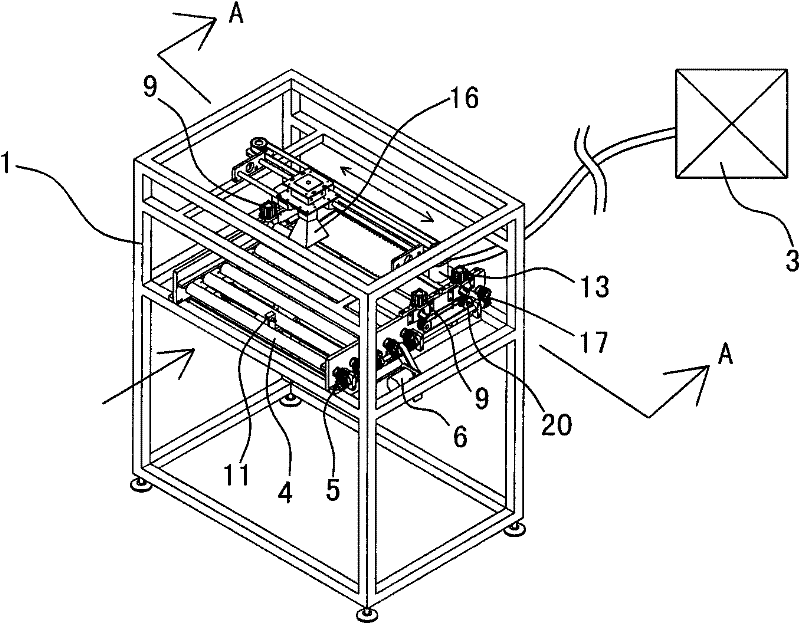

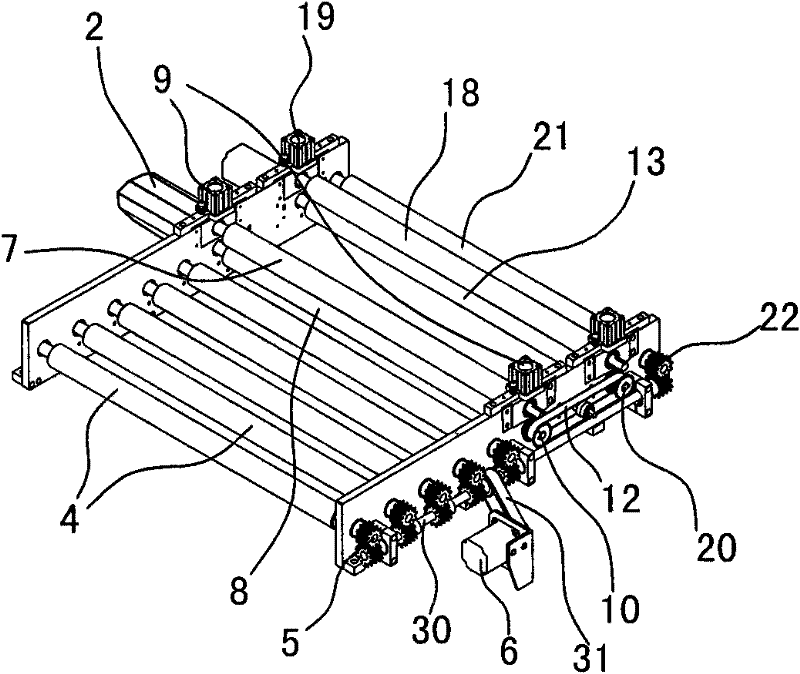

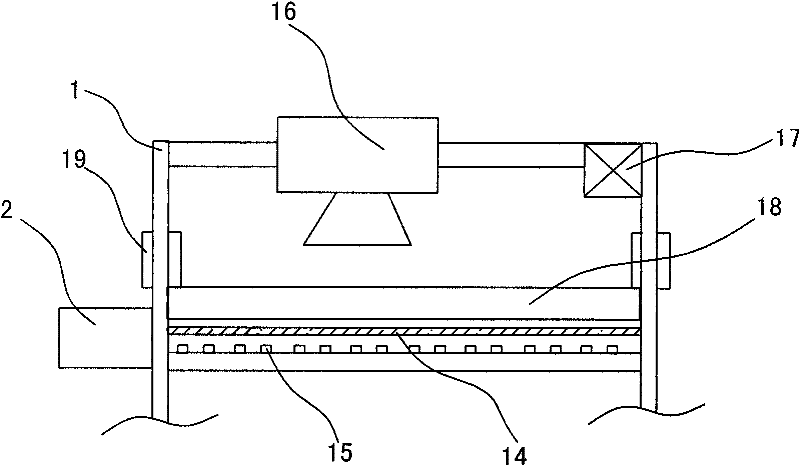

[0019] as attached figure 1 , attached figure 2 and attached image 3 As shown, this embodiment discloses an automatic inspection device for PCB circuit board defects. The automatic inspection device for PCB circuit board defects includes a frame 1, and the frame 1 is sequentially provided with a group of horizontally arranged board feeding rollers, a board feeding Pressure roller group, position detection switch 11 for detecting the position of PCB circuit board, detection light source mechanism, camera device, plate output pinch roller group, horizontally arranged plate output roller group and power device 2, the PCB circuit board defects are automatically inspected The equipment also includes a computer 3 with defect analysis, inspection and control programs; horizontally arranged board feeding rollers, board feeding pinch rollers, position detection sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com