Bowl mill ore-feeding amount intelligent control apparatus

A technology of intelligent control and ball mill, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problem of different ore particle size, and achieve the effect of saving transformation funds, improving practicability, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

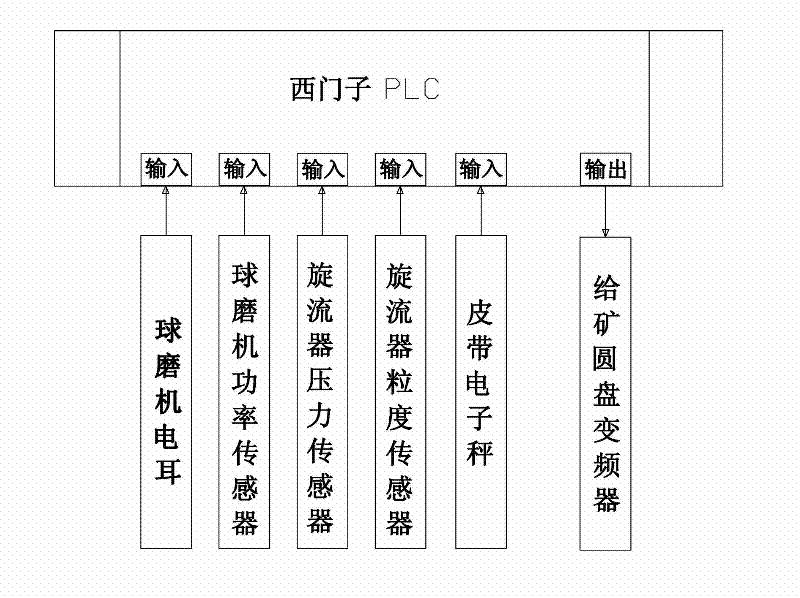

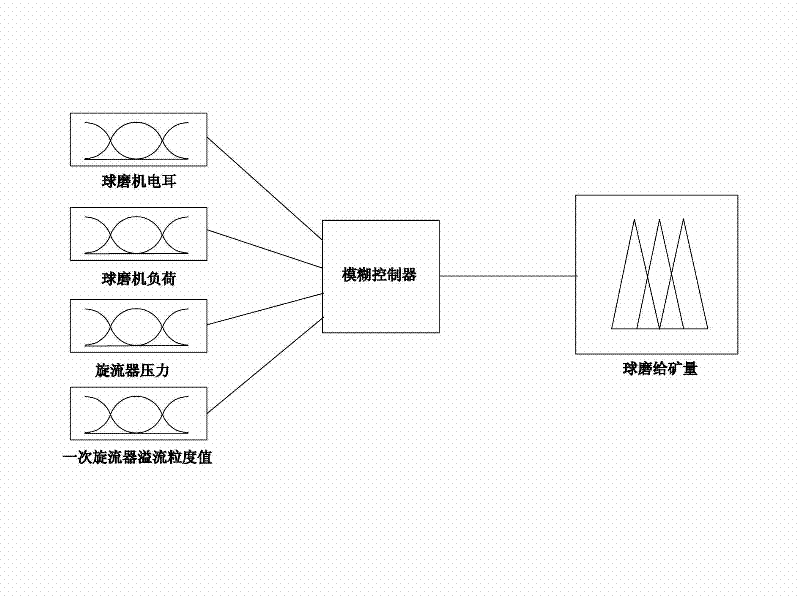

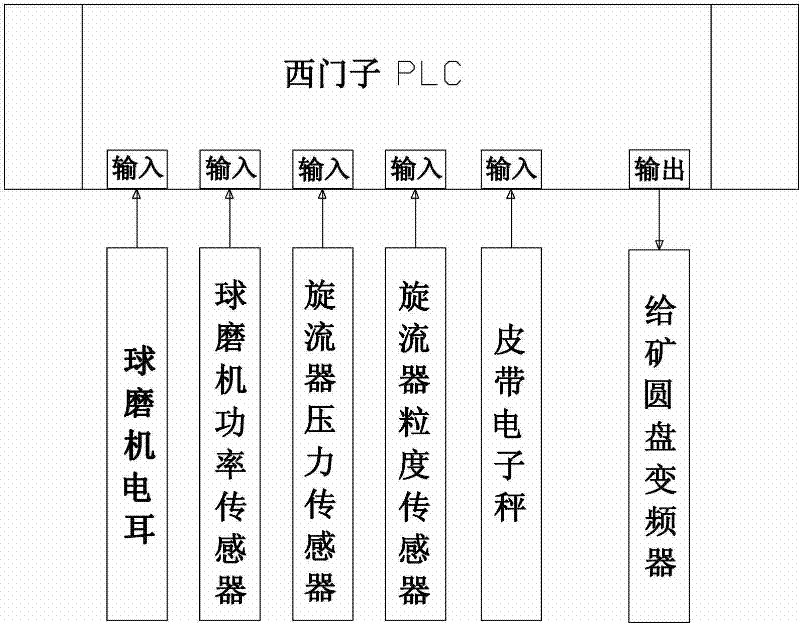

[0025] Such as figure 1 As shown, the intelligent control device for ball mill feeding amount of the present invention is characterized in that a PLC equipped with a PID controller and a fuzzy controller is respectively connected to an input parameter sensor of the PLC input interface, "manual" / "automatic" "change-over switch, ore quantity setting device is composed, the output interface of this PLC is connected with the ore disc frequency converter of the ball mill, the described fuzzy controller is an ore-feeding fuzzy controller, and the input parameter sensor includes setting The ball mill electromechanical ear on the ball mill, the power sensor of the ball mill, the cyclone pressure sensor on the cyclone, the cyclone particle size sensor and the belt electronic scale on the belt conveyor, the input parameter interface and the describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com