Dynamic load simulation testing instrument and simulation testing method

A simulation test and dynamic load technology, applied in the direction of motor generator testing, etc., can solve problems such as poor simulation and debugging, different force on the motor shaft, harsh environment, etc., to achieve convenient parameter adjustment and modification, easy load setting, and easy operation The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The dynamic load simulation tester and simulation test method proposed by the present invention will be further described below in conjunction with the accompanying drawings and a preferred embodiment-the simulation debugging cam structure.

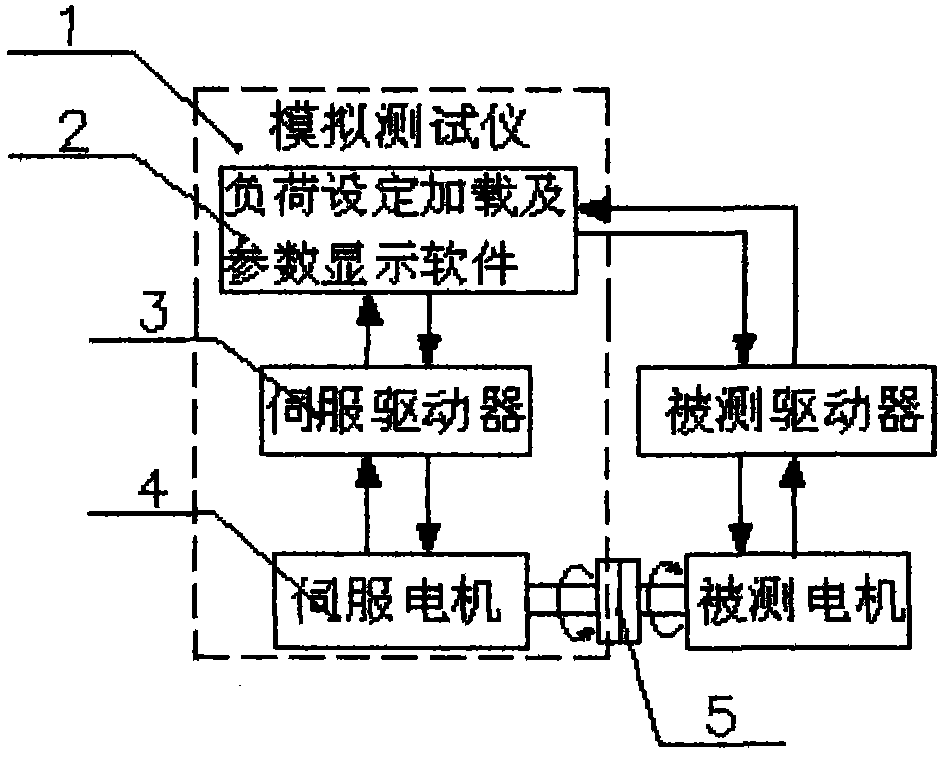

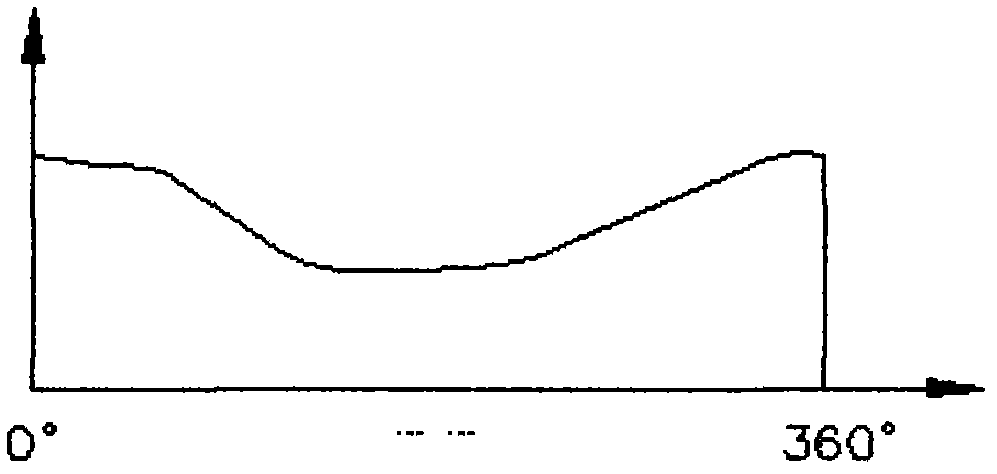

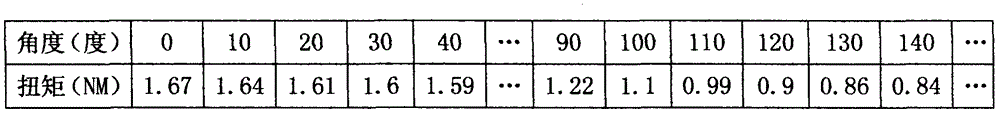

[0027] figure 1 It is a working principle diagram of a dynamic load simulation tester of the present invention. The simulation tester 1 includes a servo motor 4, a servo driver 3 with a torque drive mode, and load setting loading and parameter display software 2. Among them, the servo driver 3 is connected with the host PC by a bus. The load setting loading and parameter display software 2 can send control commands that simulate the position and torque relationship of the actual mechanical structure through the bus to the servo driver 3 to control the movement of the servo motor 4, and it can be real-time Display the actual movement information of the measured motor's position, speed, torque, etc., and display the deviation of the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com