Fire extinguishing device for biomass flue gas

A technology of extinguishing device and biomass, which is applied in fire rescue and other directions, can solve the problems of dust easily blocking mesh holes and losing fire extinguishing star, etc., to achieve the effect of small pressure loss, not easy to block, and obvious capture effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

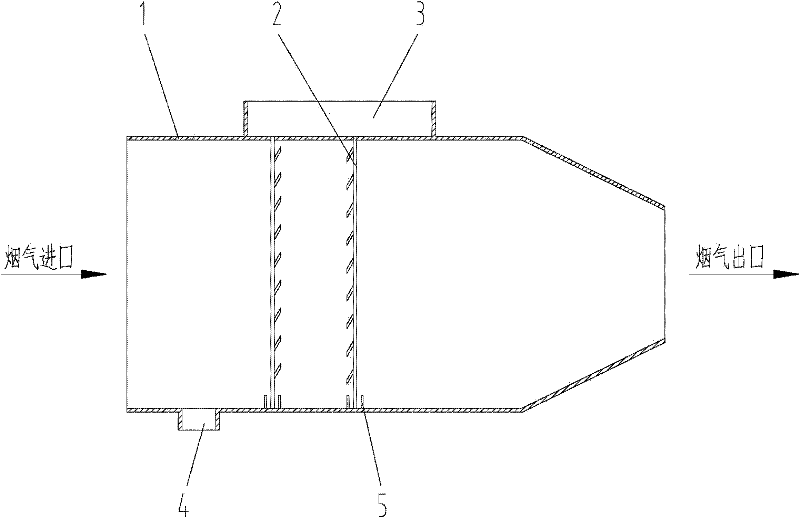

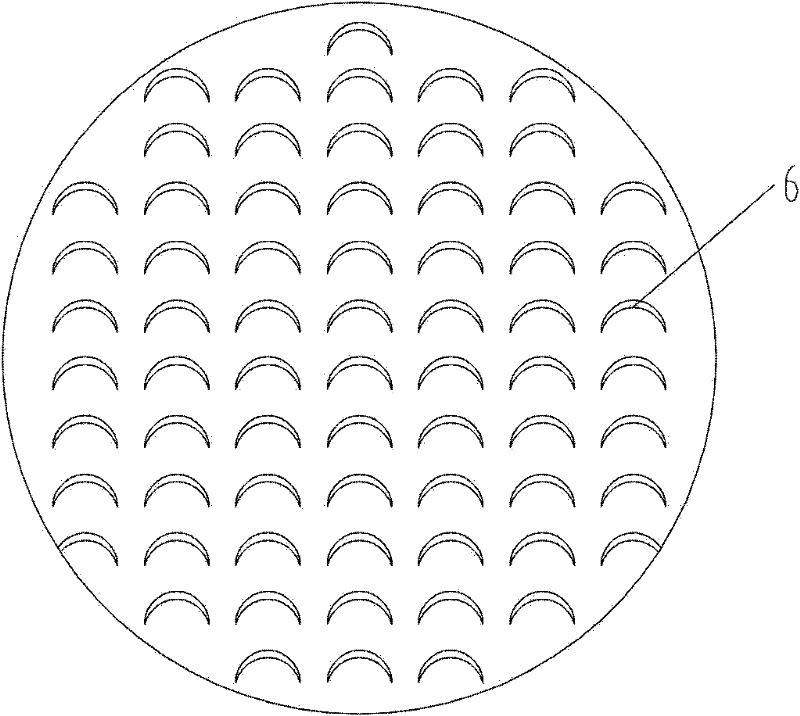

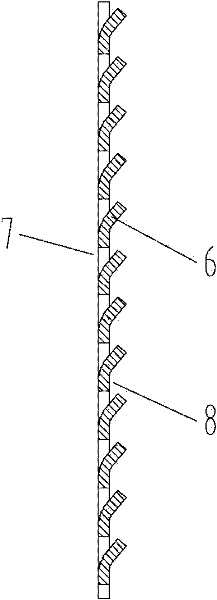

[0020] Such as figure 1 As shown, the flue gas and spark extinguishing device of the present invention is composed of a housing 1 and two orifice plates 2 . The shell is cylindrical and arranged horizontally, and it is composed of a straight section and a cone section. The inlet of the flue gas is at one end of the straight section, and the outlet of the flue gas is at one end of the cone section. The outlet of the cone section adopts a gradual design to reduce the local smoke resistance. The inner wall of the straight section of the housing 1 is provided with a slot 5, and the slot is formed by two splints welded to the inner wall of the housing. The orifice plate 2 is vertically inserted between the two splints in the slot 5 to facilitate the installation of the orifice plate. The orifice plate is made of high temperature resistant metal material, and the plane of the orifice plate 2 is perpendicular to the axial direction of the shell 1 . In addition to the vertical set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com