Double-way backwashing pressure filter tank and backwashing method thereof

A filter tank and pressure technology, applied in the direction of gravity filter, filtration separation, separation method, etc., can solve the problems of screen blockage, incomplete backwashing of filter, insufficient regeneration of filter material, etc., so as to solve blockage and improve reaction rate Rinsing effect, sufficient effect of reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: Two-way backwash pressure filter tank Take the tank body 1 with a diameter of 4 m as an example.

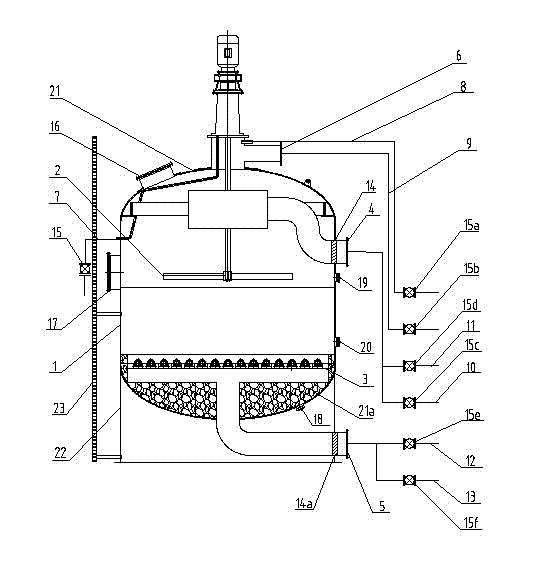

[0018] figure 1 It is a structural schematic diagram of the present invention, which shows the overall structure of the filter tank. As shown in the figure, the double-way backwash pressure filter tank is composed of a tank body 1, an agitator 2 and a filter bed 3, and the agitator 2 is in the tank body 1 is set vertically in the center, and the agitator 2 is composed of a motor, an electric reducer, a stirring shaft and blades. The tank body 1 has a water inlet 4 and a water outlet 5, and the tank body 1 is connected with an overflow pipe 7 and an exhaust pipe 8. Screen pipe 14 and screen pipe 14a are all housed on water inlet 4 and water outlet 5, and purpose is to prevent fine filter material from being washed away by water flow. A filter bed 3 is installed inside the tank body 1, and a filter material is placed on the filter bed 3. The filter material c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com