Multistation automatic pipe cutting machine

A multi-station, pipe cutting machine technology, applied in the direction of pipe shearing device, shearing device, manufacturing tools, etc., can solve the problems of wasting time and reducing production efficiency, so as to improve the dimensional accuracy of finished products, improve production efficiency, and ensure the surface Effects of Finish and Squareness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

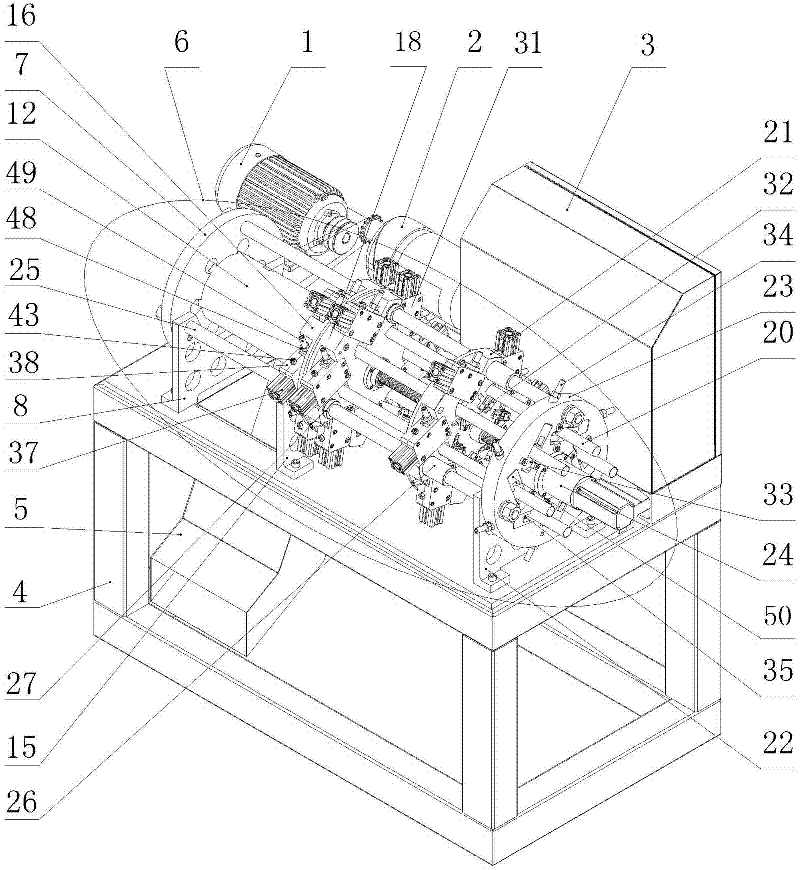

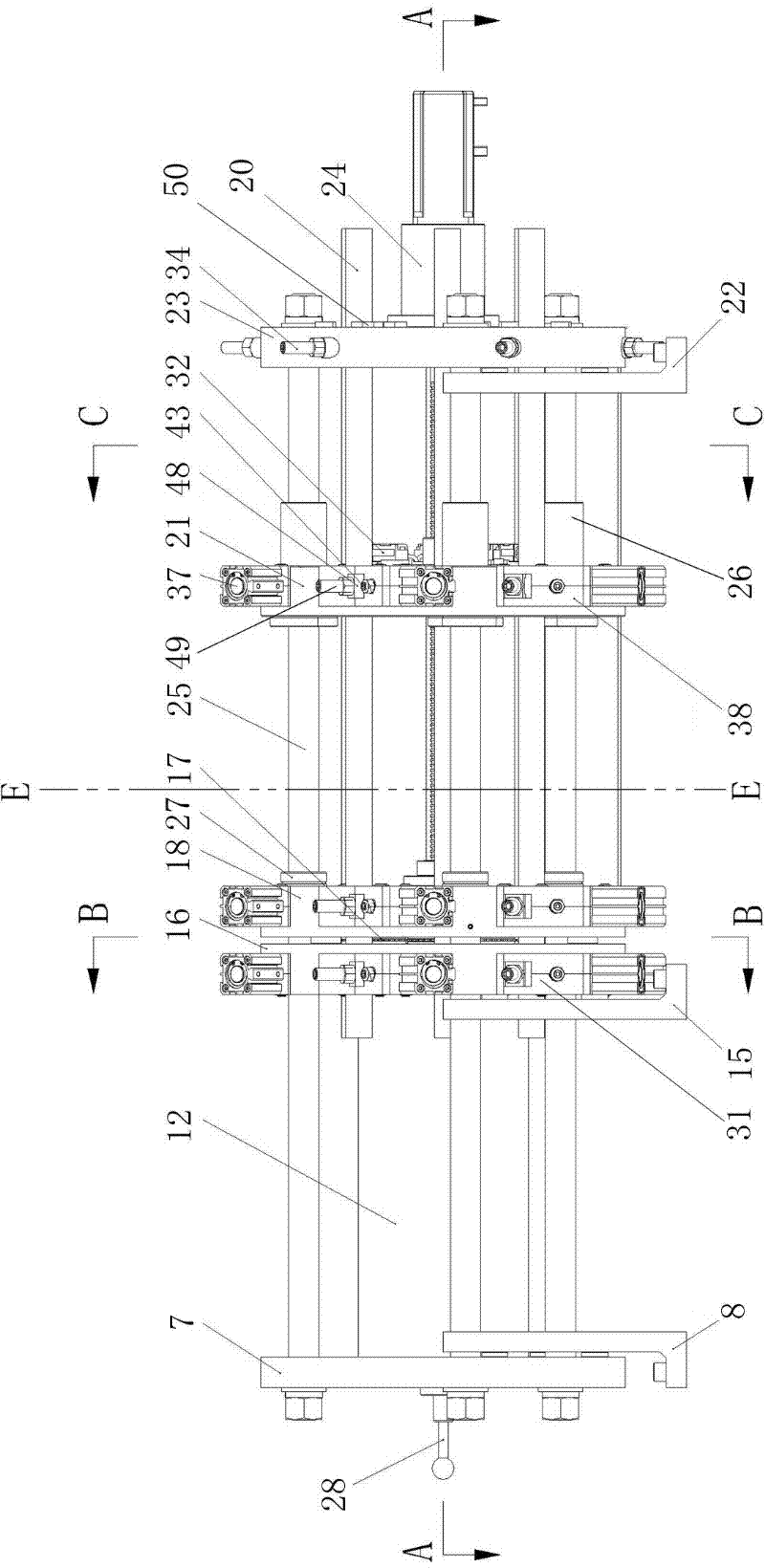

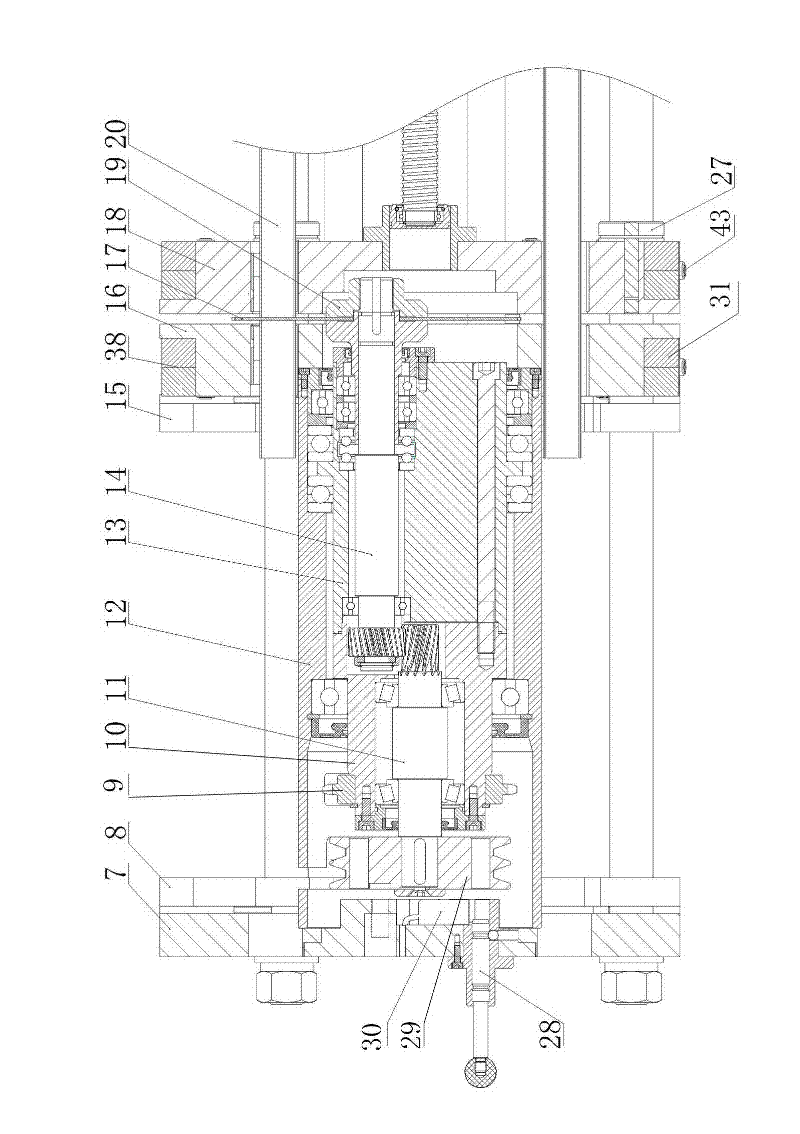

[0029] Such as figure 1- As shown in -10, the multi-station automatic pipe cutting machine includes a frame 4, a motor 1, a reducer 2 located at the matching position of the frame 4, and a mechanism for controlling the automatic coordination of each part of the machine according to a predetermined program. The electrical control box 3 is provided with a main mechanism 6 controlled by the electrical control box 3 on the top of the frame 4, and is used for carrying cutting, clamping, and feeding; 6. Three connecting plates 8, 15, 22 are used to fix on the frame 4. The main body mechanism 6 and the three connecting plates 8, 15, 22 are respectively provided with a main body fixing plate 7, a middle main body fixing plate 16 and a The fixed plate 23; the connecting plates 8, 15, 22 are connected with the main body fixed plate 7, the middle main body fixed plate 16 and the fixed plate 23 through three guide rail shafts 25 in the axial direction, and the fitting position between the...

Embodiment 2

[0033] The feeding driving device 24 is composed of a cylinder or an oil cylinder, that is, the cylinder or the oil cylinder body is fixed on the fixed plate 23, and the piston rod is connected with the feeding clamping fixed plate 21 as the power output end of the feeding driving device 24, and the others are the same as in Embodiment 1. No longer.

[0034] Specifically use the working process of the present invention: first connect the power supply and the gas source, adjust the pressure of the gas source, turn on the power switch and the reset switch on the electrical control box 3, the feeding drive device 24 drives the feeding clamping device fixing plate 21, and the The pipe material 20 clamped by the clamps 31 corresponding to the positions of a and b material holes is sent into the material hole of the corresponding processing position of the middle main body fixing plate 16 and the cutting and clamping fixing plate 18, and the clamps 31 at the corresponding positions c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap