Online-peeling rotary intaglio printing apparatus and production process thereof

A gravure printing and in-line technology, applied in rotary printing presses, gravure rotary printing presses, printing and other directions, can solve the problems of scratching and sticking, difficult to control the surface quality of transfer composite paper, very sensitive to external force, etc., to reduce waste. The effect of eliminating rubbing and sticking, and eliminating quality defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

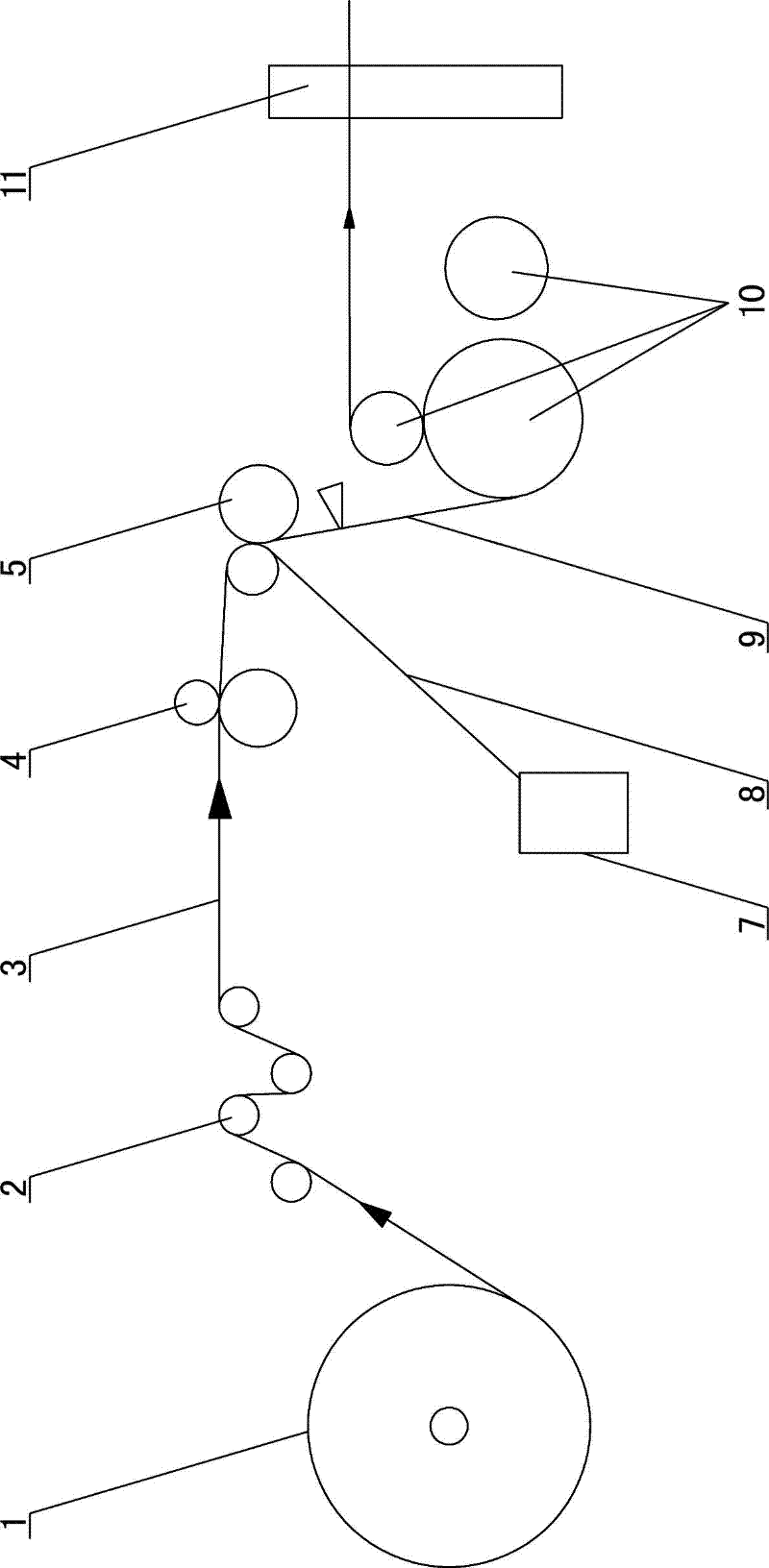

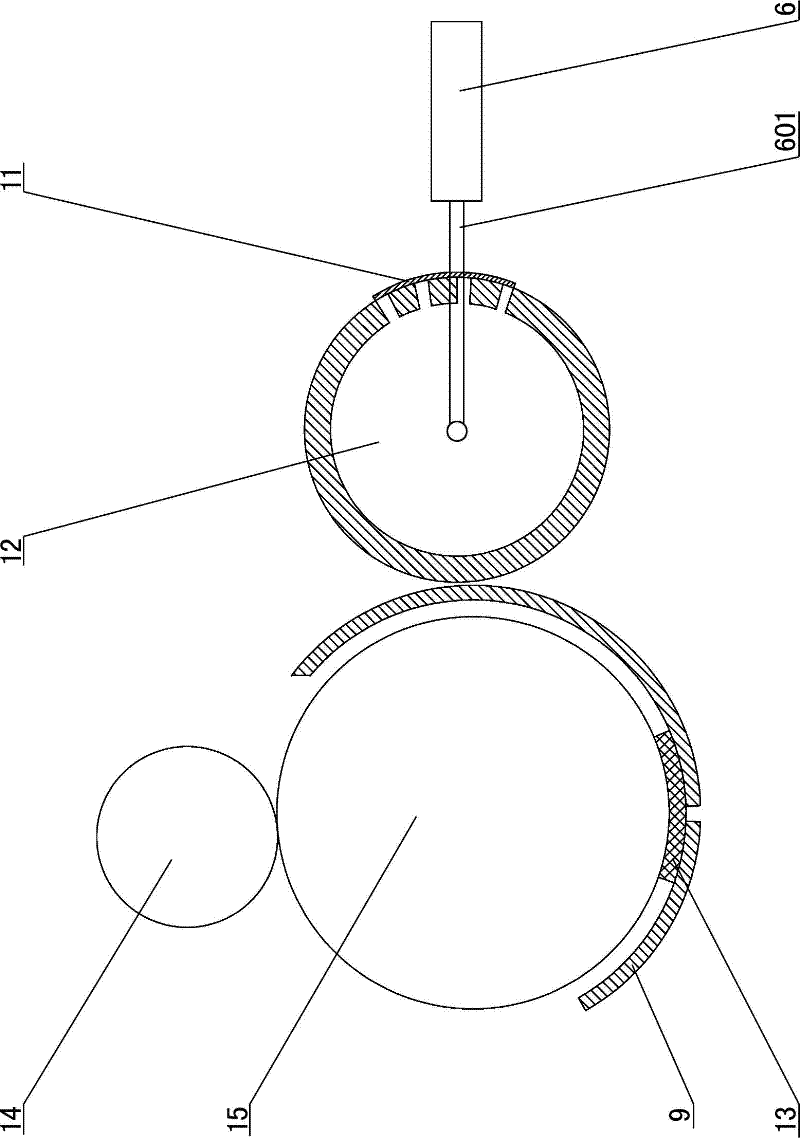

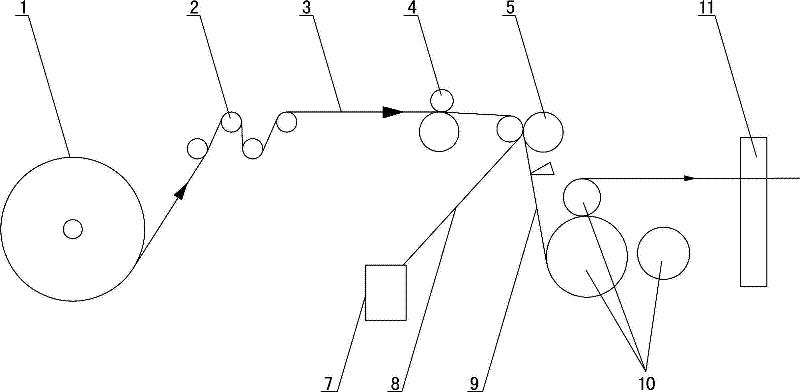

[0023] Such as figure 1 , 2 As shown, an in-line peeling rotary gravure printing equipment in this preferred embodiment includes in turn a rotary double-station non-stop unwinding machine 1, an introduction device 4, a stripping unit 5, a double-station film winder 7, and a unit 式Rotary gravure printing unit 11. In other words, the above-mentioned equipment is arranged in the order of processing. The composite paper roll with base film transfer is unrolled by the rotary double-station non-stop unwinder 1 into a strip of base film transfer composite paper 3, and then the base film transfer composite paper 3 is smoothly introduced by the introduction device 4, The base film transfer composite paper 3 is rectified by the correction device of the introduction device 4 and then enters the peeling unit 5 to peel the base film 8. The transfer composite paper 9 and the base film 8 on the surface are peeled and separated. The peeled base film 8 The double-station film winder 7 is used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com