Oil-containing refrigerant and production process thereof

A production process and refrigerant technology, applied in the petroleum industry, heat exchange materials, chemical instruments and methods, etc., can solve the problems of wasting refrigerant and lubricating oil, aggravate environmental pollution, increase maintenance costs, etc., and reduce maintenance costs , Exacerbating environmental pollution and increasing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation

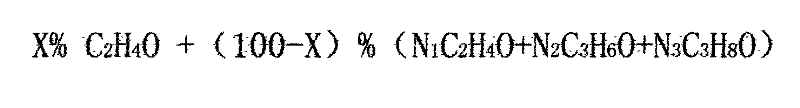

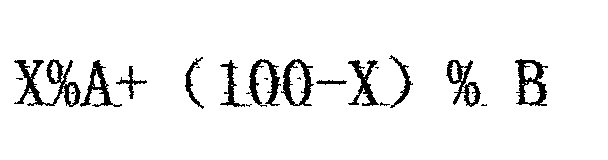

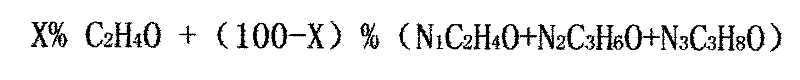

[0014] Combine below figure 1 , 2 , to describe the embodiments of the present invention. In the attached picture, N 1 , N 2 , N 3 is a constant, C 2 h 2 f 4 For R134a refrigerant, C 2 h 4 O is ethylene oxide, C 3 h 6 O is propylene oxide, C 3 h 8 O is tetrahydrofuran, N 1 C 2 h 4 O+N 2 C 3 h 6 O+N 3 C 3 h 8 O is polyether compressor oil, X% is refrigerant content, (100-X)% is lubricating oil content, A is refrigerant, B is lubricating oil.

[0015] An oil-containing refrigerant and its production process are mainly composed of a pressure vessel and a mixture of refrigerant and lubricating oil sealed in the pressure vessel.

[0016] The pressure vessel is a general pressure tank filled with corresponding refrigerant.

[0017] Described refrigerant, present embodiment mainly uses R134a (tetrafluoroethane C 2 h 2 f 4 ) as an example, it is currently widely used in automotive air conditioning systems.

[0018] Described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com