Testing device for deep wells and high-temperature and high-pressure wells

A high temperature and high pressure, testing device technology, applied in wellbore/well valve devices, isolation devices, wellbore/well components, etc. The effect of eye collapse, stable liquid and gas flow rate, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0041] In the present invention, for the convenience of description, the description of the relative positional relationship of each component is based on the description attached to the description. figure 1 For example, the positional relationship of top, bottom, left, right, etc. is determined according to the layout direction of the drawings in the specification.

[0042] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

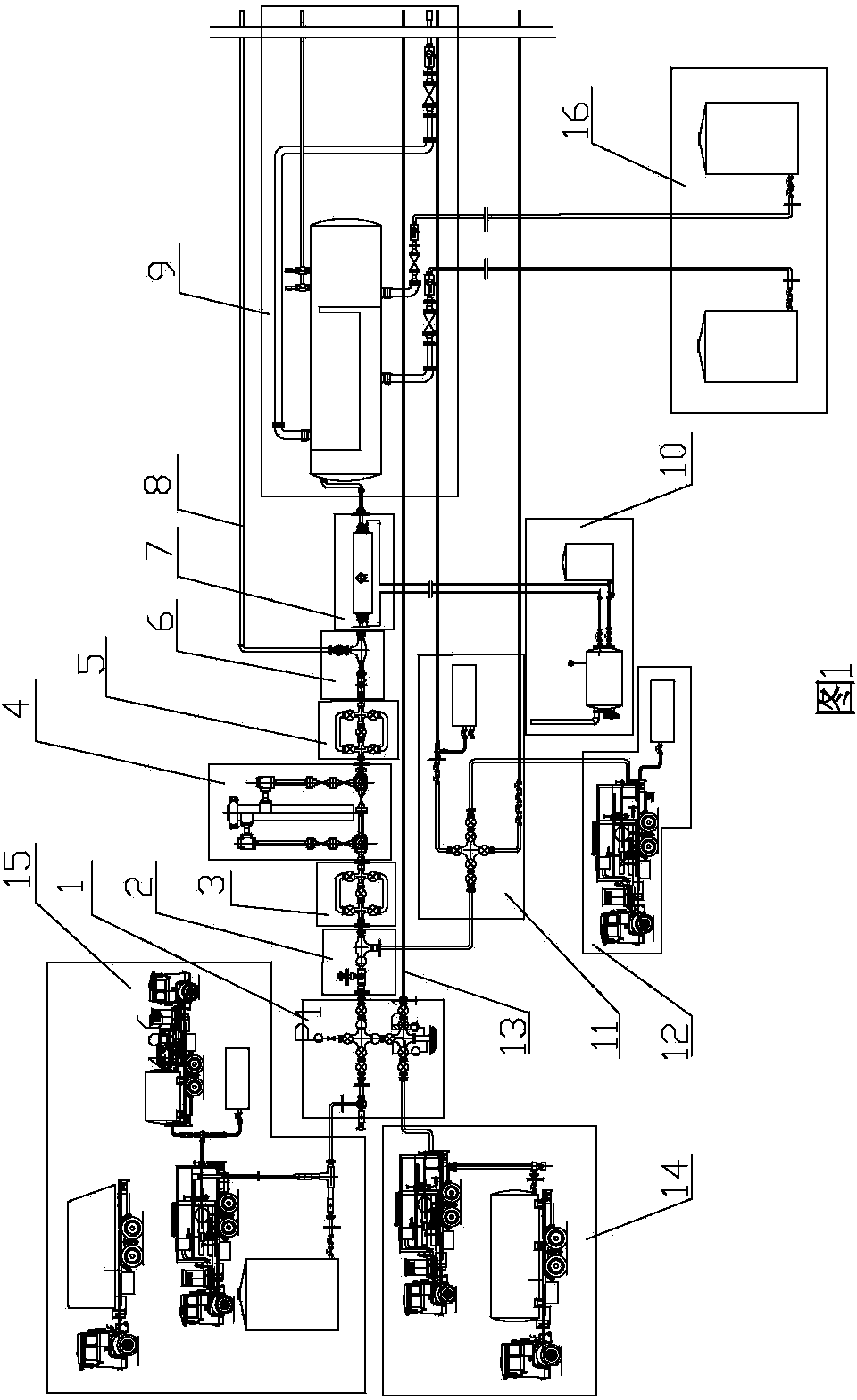

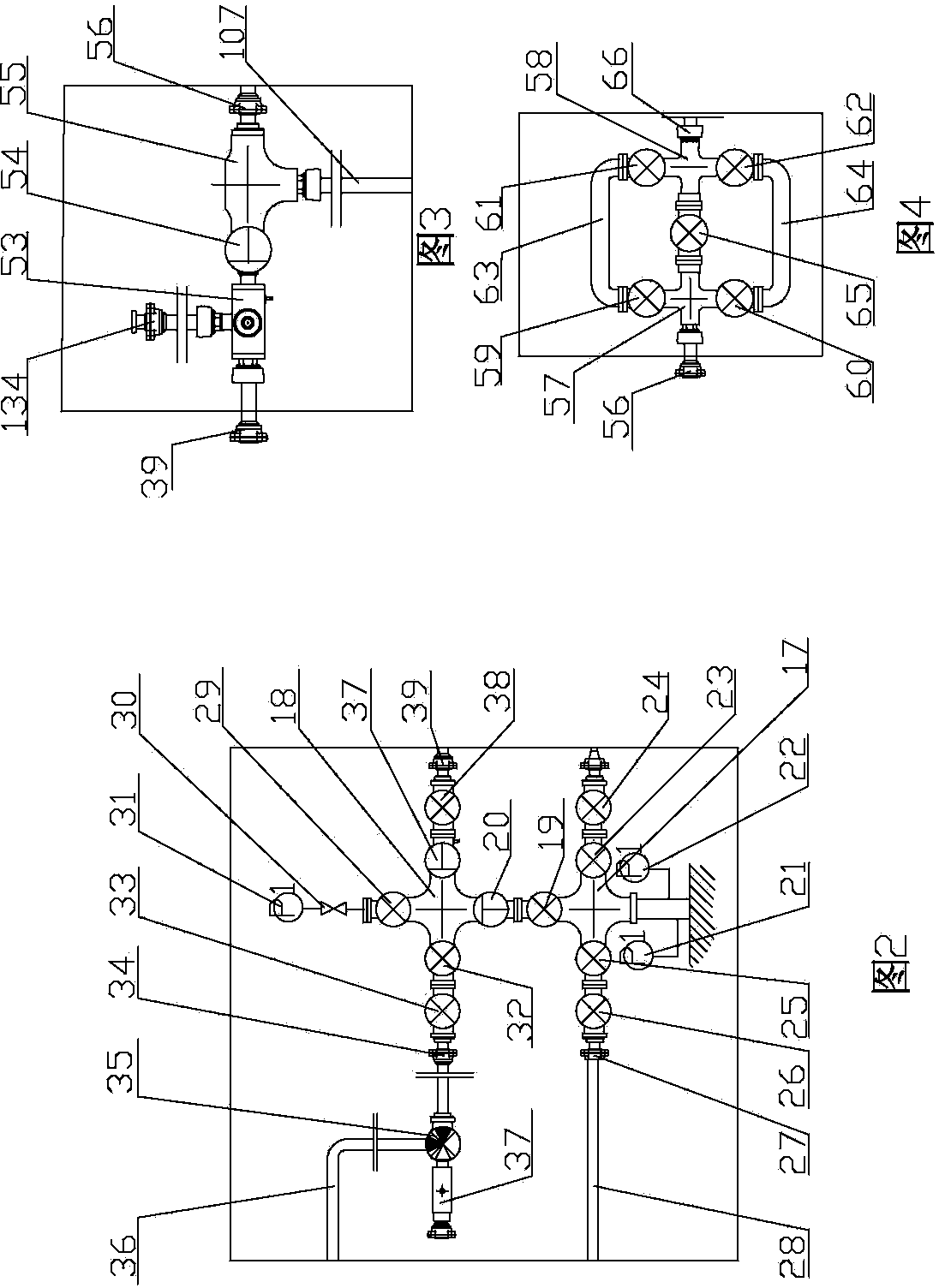

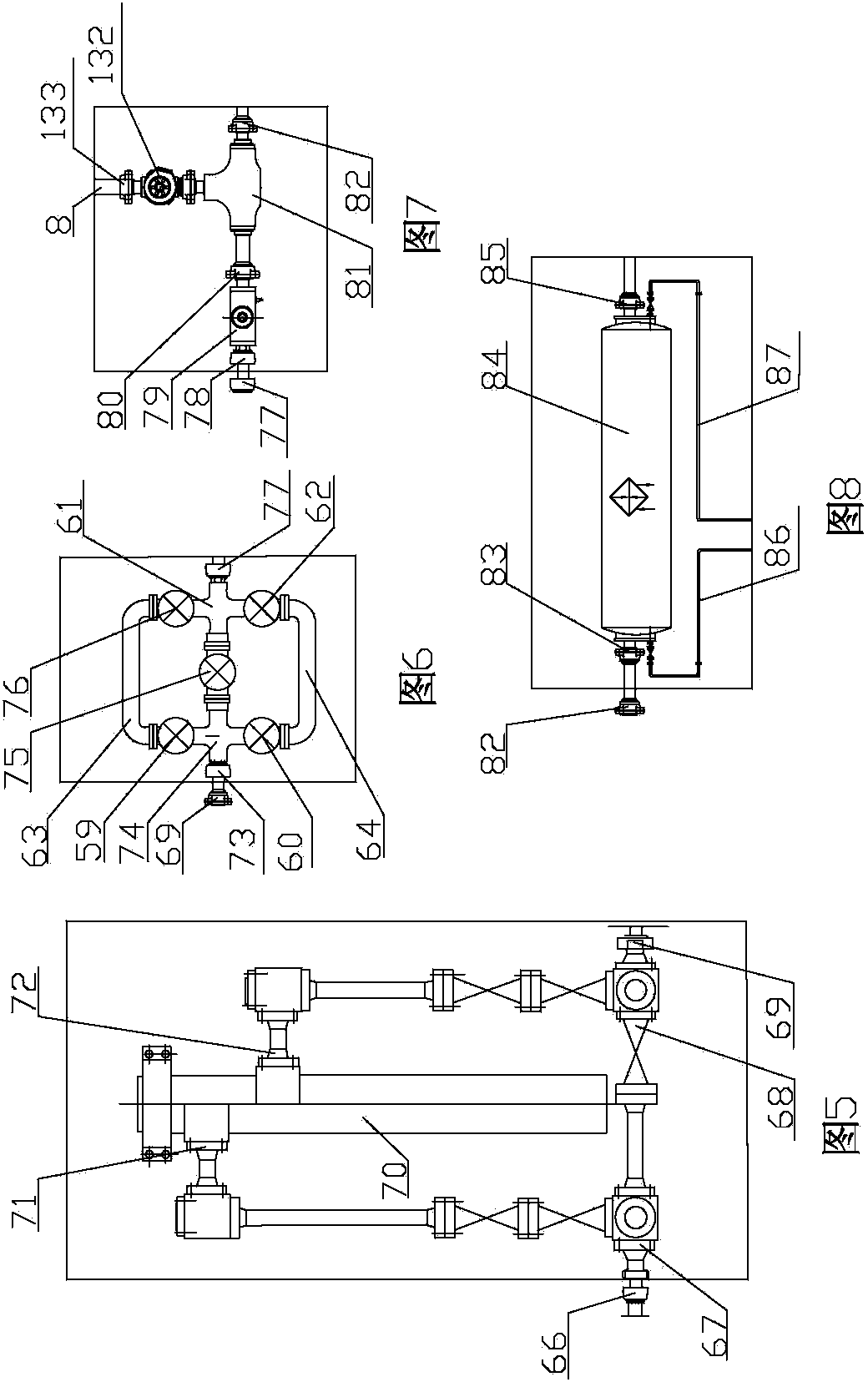

[0043] as attached figure 1 As shown, the deep well and high temperature and high pressure well testing device includes a gas production wellhead 1, an injection device 2, a front nozzle manifold 3, a desander 4, a rear nozzle manifold 5, an emergency vent valve 6, a heat exchanger 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com