Induction cooker and temperature measurement method thereof

A technology of induction cooker and electromagnetic heating coil, which is applied to thermometers using electric/magnetic elements that are directly sensitive to heat, using electromagnetic means, thermometers, etc., can solve the problems of increasing battery replacement costs and inconvenient use by users, and achieve simplified structure, Accurate temperature measurement and accurate temperature measurement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

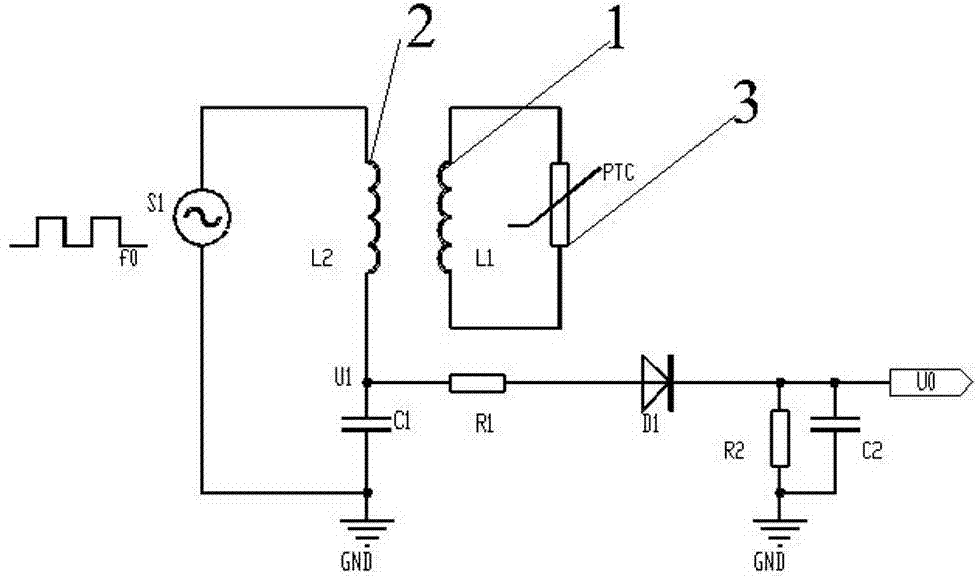

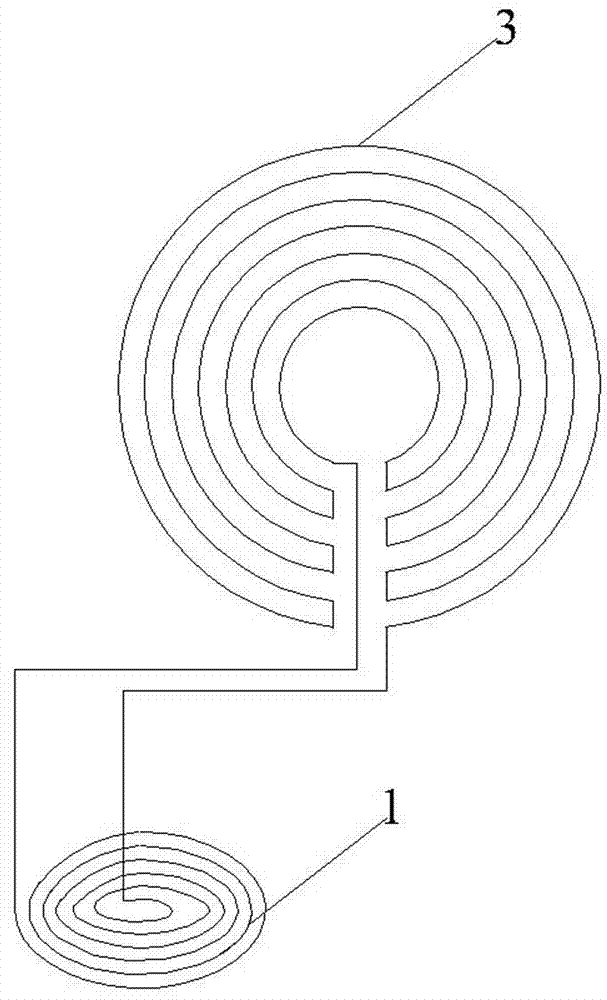

[0027] The precise temperature measuring device for an electromagnetic oven shown in Example 1 includes an electromagnetic oven porcelain plate, an electromagnetic heating coil and a control circuit.

[0028] At least one positive temperature coefficient temperature sensor 3 pattern is printed on the upper surface of the panel to achieve contact with the heated pan, and a first coil 1 is printed on the panel with conductive paste, and the first coil 1 is in contact with the heated pan. The positive temperature coefficient temperature sensor 3 is electrically connected, and also includes a second coil 2 magnetically coupled with the first coil, and a processing circuit electrically connected between the second coil and the control circuit.

[0029] The processing circuit includes: at least one first capacitor, an oscillating signal generator connected in series with the first capacitor, the oscillating signal generator is used to provide an oscillating signal with a fixed freque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| q value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com